Limit switch: what is it, marking + connection rules

Almost all automated systems contain such a device as a limit switch, which is responsible for turning them off when the moving part reaches a certain point. In lighting control systems, limit switches are used as sensors. When programmed circumstances arise, they form a signal.

We will tell you all about the functional purpose and types of trip devices. In the article we presented, we have described proven wiring diagrams, listed the connection rules. Marking features are given, selection tips are given.

The content of the article:

What are limit switches?

Limit switches are electrical devices designed to open and close the working circuit. Mount them on moving mechanisms to limit their movement within predetermined boundaries. The functions that these devices perform are identical to the standard switch.

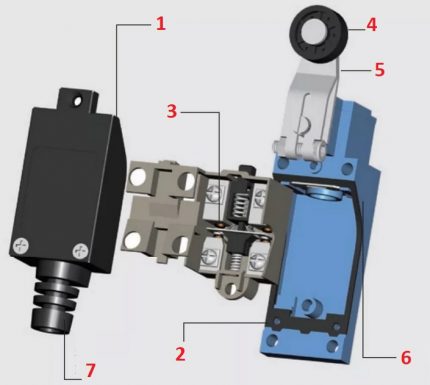

The filling of the limit switches is enclosed in a durable case, most often metal. All its elements are optimized for easy fastening and easy orientation in space.

Bright, different colors of LEDs allow you to control the power supply and the response of the sensor. Two pairs of contacts, most often available in the trailer, make it possible to monitor the status of its connection.

If the transmission of the signal does not follow with a closed pair, it does not return, this indicates a malfunction of the cable leading to the switch. After the sensor is triggered, it is possible to use an open pair of contacts to pass the signal.

Sensitive sensors are the foundation in leakage protection systems. When water is detected, for the identification of which they are intended, the devices not only signal an alarm situation in sound and color mode, but also block the operation of the systems through which water is transported.

Functional classification

There are three main groups of limit switches: mechanical, non-contact, magnetic. The main function of all these devices is to automatically disconnect the working mechanism when it reaches the established position by its moving part. These switches serve not only to open the circuit, but also to connect it.

The operation of the circuit in the end sensors is coordinated in two ways: by directly acting on the movable contacts and positionally controlling them. In the first case, they are called contact, in the second - non-contact. An example of contact limit switches are sensors responsible for closing automobile doors.

Sensors of this type can not only turn on and off the mechanisms, but also set the position of the subject of control. These include float switchesas well as fuel level sensors. The signal for their operation is a change in resistance corresponding to a certain liquid level.

Minus contact sensors in the presence of mechanical moving parts, relatively short service life due to ineffective protection against moisture and dust. The advantage is simple design, installation and operation. The proximity switches are much more reliably protected from external influences. More durable is their resource.

Mechanical Ends

The control of the end switches of this type can be roller or lever. They work as soon as the control mechanism in the form of a wheel, button or lever is subjected to mechanical stress.

In this case, a change in the position of the contacts occurs - they can close or open. The process is accompanied by a signal - control or warning.

Most often, limit switches have two contacts - open and closed. There are single end devices, but they are rare. In any case, there are contacts in each case, and a working diagram with their numbers is shown on the panel.

The design of the roller VK provides for turning off by pressing the actuator on the button in the form of a small rod. Since it is connected with dynamic contacts, at the moment of contact, the supply circuit opens.

The difference between the lever switches is that their movable contacts are connected via a rod or through a rod to a small lever. The action occurs when the actuator clicks on this lever.

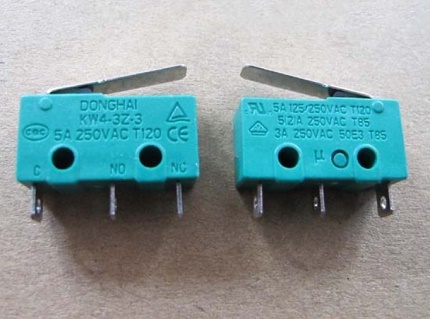

In addition to standard end devices, there are microswitches. They work on the same principle, but their adjustment during installation requires greater accuracy due to the small stroke. To increase the working stroke, they resort to such a technique as the inclusion of an intermediate element in the circuit - a lever with a roller.

This type of circuit breaker is used both in production and at home. The design of the elevator used a large number of KU.

Among them is a switch in the form of a sensor, limiting the minimum and maximum elevator stroke, signaling a cable break, giving a signal to open the door and performing many more actions. On the doors in many apartments there are microswitches that turn on the light in the room when it is opened.

In automobiles, such mechanical end sensors are incorporated into alarm and lighting circuits. Their feature is the presence of a single input with a positive potential connected to it. The housing is a negative terminal, pressed against a metal element on the car body, free of paint.

With the mass of the car, this element is connected by cable. The main condition is that the switch must not come into contact with a wet surface. Connect the end sensors when installing a car alarm using a circuit. Their outputs can be installed both on the doors and in the passenger compartment on lighting fixtures.

To turn on when the door is opened, and turn off when it is closed, perform a short to positive. If there is a backlight for the ceiling of the cabin and doors, a trailer block is used that performs various functions. As a result of the operation of the block, important sensors are blocked when trying to open locks.

Features of contactless limit switches

One of the varieties of limit switches is their non-contact modification (BVK). Communication devices configured to operate when it falls into the sensitivity zone of a specific object.

There are no moving parts in the device itself, just as there is no mechanical contact between the object of influence and the switch element configured on it.

BVK consists of the following parts:

- sensitive element;

- power key;

- component that analyzes the signal.

The distance at which the device begins to act is set based on the modification of the sensor and the requirements of the process. The exclusion of both moving and rubbing elements from it significantly increases the reliability of these devices.

Non-contact sensors or, as they are also called, proximity sensors have extensive functionality. There are two categories - switches and position sensors.

The first task of the IOO is to detect the position of the subject. In addition, the sensor performs counting, positioning, separation, sorting of objects. He can control the speed, movement, calculate the angle of rotation, adjust the skew and perform many other actions.

In domestic conditions proximity switches while mainly used in the organization of lighting control. However, in the field of system design “Smart home” it has a much larger scope and much more prospects.

Sensitive instruments are used in industry, in the transport industry, as an element of automation, in oil refining. By the principle of detecting approaching objects, BKVs are distinguished inductive, capacitive, optical, ultrasonic.

Inductive proximity sensors

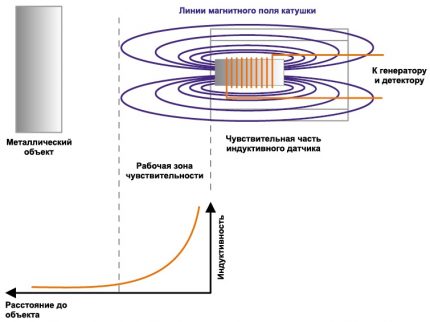

They are configured for both metallic and amorphous materials. Among those reacting to metal, there are magnetic and ferromagnetic options. Inside the sensor is a core - metal or magnetized.

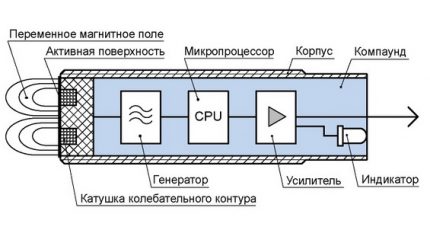

If you describe the design of such a sensor in more detail, it consists of a transducer, including a copper coil located in a ferrite cup. Its functions include redirecting the vector of electromagnetic lines to the front of the circuit breaker.

The oscillator in the circuit can be either with a fixed negative resistance, or any other type. The magnetic field lines are oriented perpendicular to the direction of the current flowing along the turns of the magnetized core.

An alternating force field is caused by an alternating voltage at the core inputs. The next important node is the signal shaper, which creates hysteresis and the range of the control signal. It includes a detector controlled by a trigger.

The key point in the functioning of the induction limit switch is the changes that occur when an object is approaching or moving away. As soon as the voltage threshold exceeds the permissible value, the sensor is triggered by connecting a trigger that opens the key.

Capacitive proximity switches

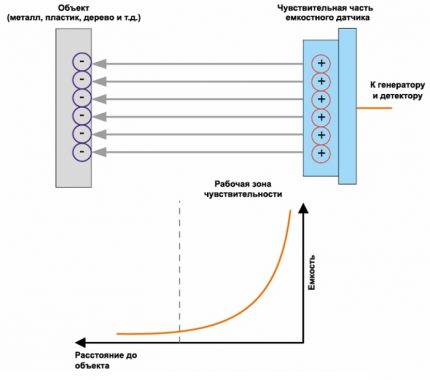

After the appearance of the object, the vibrator circuit of the capacitive device starts, the time parameters are set. As the subject approaches the sensor, the capacitance of the latter increases, and the frequency produced by the multivibrator decreases.

As soon as the frequency threshold is exceeded, the device turns off. Many models operate on this principle. motion sensorsturning off and on the light bulbs when an object is detected in the sensitivity zone.

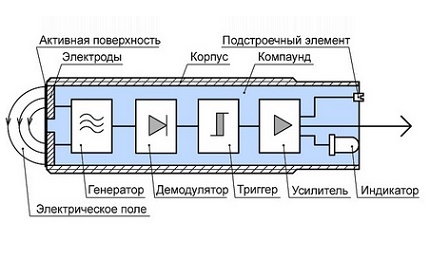

The structural diagram of a capacitive sensor resembles an inductive device: both models have a generator and a detector.

In addition to the generator that generates an electric field, their design includes such basic parts as a demodulator. It acts as a converter of the amplitude of high-frequency oscillations with a simultaneous change in voltage. The next important component is the trigger, which is responsible for a certain signal level, switching, and hysteresis dependence.

To increase the input signal to a specified value, an amplifier is included in the capacitive circuit breaker circuit. The LED indicator is responsible for monitoring the settings and operation of the device.

A switch such as a compound protects the switch from moisture and solid particles. A plastic or brass case protects everything inside it from mechanical damage. The kit also includes fasteners.

The switching element in this device is located on the capacitor and is a plate interacting with a vibrator. The role of the threshold element is performed by a comparator connected to a vibrator. The latter, in turn, is connected to a frequency and voltage converter.

The difference between capacitive and inductive models is that the former respond to air humidity and density change. The second ones are insensitive to such influences.

The device of ultrasonic switches

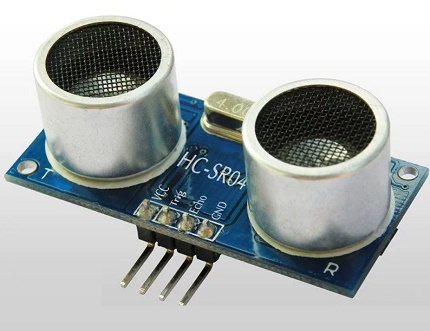

The design of ultrasonic limit switches provides for the presence of quartz sound emitters forming pulse waves with a length of 100 - 500 kNc, and a receiver whose settings correspond to a certain frequency.

When changing the amplitude of sound waves as a result of maneuvers of a moving object, the BVK microswitch captures new values and, based on this, controls the output signals.

The principle of operation of ultrasonic sensors is based on a change in the time during which the sound wave moves from the sensor to the controlled object. The detection distance of such devices is quite large - up to 10 m. Their great advantage is that they can detect an object of any shape and color that reflects sound.

Such sensors are used to detect objects with a flat surface, occupying a perpendicular position with respect to the midline of detection.

Inaccuracies in their work can cause:

- Suddenly arising air currents of high power, amplifying or attenuating the wave.

- A sharp change in temperature.With a large amount of heat emitted by the object, the speed of the propagated waves changes.

- Deviation from the vertical angle between the horizontal plane of the object and the axis of the sensor. If this error exceeds 10⁰, the sensor does not work.

- Angular outlines of the object. In this case, its identification is very difficult.

Oscillations propagate in a solid, gaseous, liquid medium, and the speed depends on the corresponding parameters. Ultrasonic sensors do not have moving parts, so there is no relationship between the number of cycles and the life of the device. They are characterized by increased resistance to influences of all kinds from the outside.

Optical contactless devices

BKV of this type control objects, both overlapping radiation and reflecting it. When an object enters the space between the switch and the light source, the sensor interrupts the light flux. The element responsible for this action can be relay or semiconductor. The response radius extends to 150 m.

Proximity sensors operate in a wide temperature range - from -60 to + 150 ° C. They withstand a pressure of about 500 bar, can be operated in an aggressive environment and even in conditions of increased explosion hazard.

Magnetic End Types

This type of switch, otherwise called float switch or reed switch, gradually replaces mechanical models. Their contacts change position when they are at some distance from the magnet. In this case, a signal is supplied to the control circuit.

In the reed switch there is one or two contacts made of a special material - a ferromagnet. The magnetic trailer is small in size. They place it in a case made of plastic or glass, and are mounted in its circuit into an electrical circuit.

The contacts in such a switch are open, closed, switchable. In devices of the first type, the contact closes when activated. Normally closed contacts open in similar circumstances, and switches behave according to the situation.

The choice of model depends on specific circumstances. Reed switches are used in the construction of sliding gates. With their help, the structure is stopped when it reaches its extreme position when opening or closing.

Some float models are used as part of a burglar alarm at the entrance to the house. When the door is closed, the circuit is closed due to the influence of a magnetic field on the trailer. The opening door provokes the movement of the magnet and the opening of the contact, which triggers the alarm.

The fact that there is no mechanical contact in this design is its advantage that increases longevity. They differ in the simplest structure based on the interaction of magnetically controlled contacts with a conventional magnet.

Rules and specifics of connection

Although the limit switches themselves are quite simple in construction, they are used in equipment with complex electrical circuits. Therefore, their connection should be carried out by specialists and strictly according to the principle schemes, based on the features of the technology.

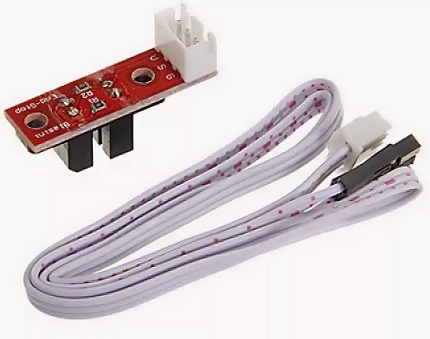

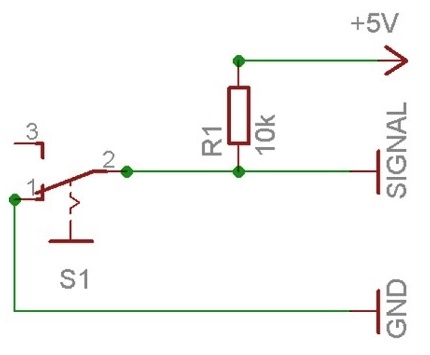

Consider the example of connecting a simple mechanical switch in a 3D printer. This is necessary in order to set the extreme coordinates for its carriage. The plug-in trailer has 3 contacts - COM, NO, NC. When the sensor is open, the first and last contact are under + 5V voltage. The second contact (NO) is grounded.

Connect the sensor using two wires - red and black. When the appliance trips, a typical click should sound. The indicator switch is connected in the same way, but it also has a third wire - green.

Its operation is signaled by a lit LED and a click. Its connectors on the board have the designations: for the red wire V (+5 V), for the black - G (ground), for the green - S (signal).

The same letters indicate the connectors on the optical switch. It will more accurately control the operation of the carriage, but may malfunction in dusty and sunlight conditions. The triggering of the optical pair is accompanied by the inclusion of a light-emitting diode and occurs completely silently.

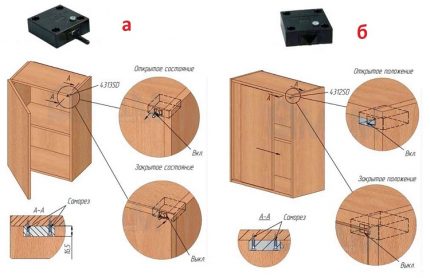

Limit switches are widely used by furniture makers, installing them in sliding wardrobes. Connection is performed according to the instructions attached to each model. The diagram indicates the mounting location of the plastic structure with the key. For the middle door, it must be installed so that it is not an obstacle for the correct movement of the other door of the section along the guides.

In the case of installing a limit switch for a swing door, it is fixed with self-tapping screws inside the cabinet. When closed, the door presses the button, opens the circuit and the lighting does not work. In the open - the door releases the button and the lighting turns on.

Limit Switch Marking

Each of these switching devices is labeled accordingly. Having decrypted it, you can get all the information about a specific model of the limit switch. If there is a VU222M record on it, then it means that you have a switch of the terminal series VU222 in front of you. The moving element is a modernized lever.

In detail, we decode for example the marking of the VP 15M4221-54U2 switch. It is equipped with one movable acting element of the 15 series. It has one make contact and one make contact, equipped with a pusher with a roller.

The protection level is IP54 on the drive side, “U” indicates the climatic version, and number 2 indicates the category of placement. The product complies with TU U 31.2-25019584-005-2004.

Industry Leading Manufacturers

Many companies produce such sensors. Among them are recognized leaders. Among them is the German company Sick, as the main manufacturer of such high-quality products. Autonics supplies inductive and capacitive type proximity switches to the market.

Non-contact sensors of high quality are produced by the Russian company TEKO. They are characterized by ultra high tightness (IP 68). These limit switches work in the most hazardous environments, including explosive ones, and various installation methods are available.

Limit switches of the Ukrainian manufacturer Promfaktor are popular. Switches and switches end VP, PP, VU are produced here. The warranty, subject to all operating rules, is 3 years.

Conclusions and useful video on the topic

Video # 1. Popular about limit switch:

Video # 2. Installing HF on a homemade CNC machine:

The purpose of the limit switches can be very different. They are used both in complex industrial systems and in everyday life to increase our comfort. The main thing is that their connection to the electrical circuit must be performed only after complete removal of voltage.

Please write comments in the block below. Perhaps you will share information that will be useful to site visitors. Leave posts with recommendations, post photos on the topic, ask questions.

Intermediate relay: how it works, labeling and types, nuances of adjustment and connection

Intermediate relay: how it works, labeling and types, nuances of adjustment and connection  Thermal relay: operating principle, types, connection diagram + adjustment and marking

Thermal relay: operating principle, types, connection diagram + adjustment and marking  Pressure switch for compressor: device, marking + wiring diagram and adjustment

Pressure switch for compressor: device, marking + wiring diagram and adjustment  Electromagnetic relay: device, marking, types + subtleties of connection and adjustment

Electromagnetic relay: device, marking, types + subtleties of connection and adjustment  380V electromagnetic starter: device, connection rules and selection recommendations

380V electromagnetic starter: device, connection rules and selection recommendations  Pulse relay for lighting control: how it works, types, labeling and connection

Pulse relay for lighting control: how it works, types, labeling and connection  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements