Fire safety requirements for gas boiler rooms: subtleties of arranging rooms for gas boiler rooms

Gas boiler houses, both domestic and central, belong to facilities that need increased attention and compliance with all the rules for the arrangement established in legislative acts. The strict fire safety requirements for gas boiler rooms must be strictly observed and only a responsible attitude can guarantee the safety of people living nearby.

Why is it so important to follow the recommendations of specialists and are boiler houses really so dangerous or is it just a myth designed to add some trouble to their construction?

Let's look at all the nuances.

The content of the article:

Terms and definitions for gas boiler plants

To make it easier for you to understand the essence of the conversation, we’ll immediately explain what and what is called.

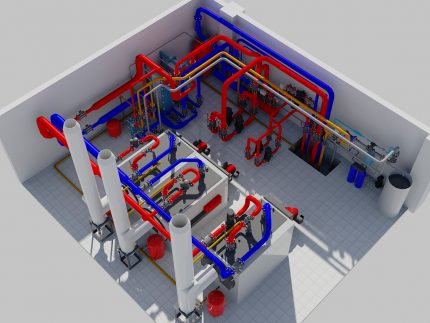

Boiler room - this is a separate room or building, a complex of buildings and structures, with technological facilities designed for the processing and distribution of thermal energy received from the incoming gas resource.

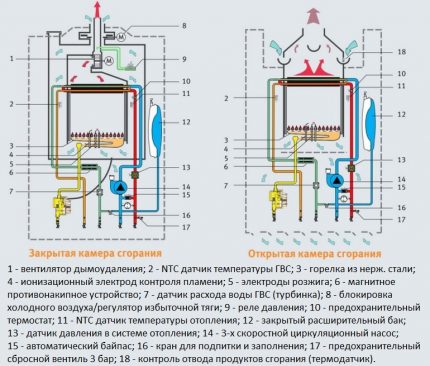

Boiler plants - this is the equipment of the boiler room, which includes a heat generator, in our case, a boiler, various devices and mechanisms that allow us to carry out and control the generation of thermal energy (this includes chimneys, ventilation, signaling devices, various automation, remote sensors, etc.) for the production needs of residential, public buildings and premises for other purposes.

Units for gas boiler houses are almost always automated, which facilitates the process of processing and supplying fuel, in comparison with solid fuel.

Consumer- a subscriber receiving thermal energy in the form of heating or hot water, coming from the boiler room legally in accordance with the concluded agreement, the right of ownership, residence.

Central boiler rooms - buildings for heating purposes, providing heat supply to several objects.

Decentralized- autonomous boiler rooms.

OPO- hazardous production facility.

In addition, by appointment, heat supply facilities are divided into:

- Heating, that is, designed to equip heating, ventilation, air conditioning and hot water structures with thermal energy.

- Heating and manufacturing - the same as in the first case with the addition of technological support for industrial buildings.

- Production - only for technological heating. Used in industry.

Fire safety of boiler rooms is a priority in approving design documentation for the installation of gas-powered appliances.

Now let's look at the documentation that governs the fire safety requirements of buildings.

Fire safety standards for boiler rooms

To understand the rules and safety standards, you need to know the laws that will help to avoid unnecessary paperwork and requirements for conversion.

Here are the main ones:

- SNiP 21-01-97 * (SP 112.13330.2011) - about the fire safety of buildings.

- PP of the Russian Federation No. 1521 of December 26, 2014 - a list of mandatory standards, including gas systems.

- Rosstandart order of 10/03/2011 N 5214- a list of documents on the basis of which, on a voluntary basis, compliance with TR on the safety of gas distribution networks is ensured.

- SP 62.13330.2011 - Gas distribution systems.

- SP 42-101-2003 - the basic rules for the construction and design of gas distribution systems.

- PP number 870- TP safety of gas distribution networks.

- SP 402.1325800.2018 - gas consumption design rules.

- SP 3 (4, 5, 6, 7, 10) .13130 - rules that protect fire systems.

- SP 60.13330 2016 - heating, ventilation and air conditioning.

- SP 402.1325800.2018 - “Residential buildings. Rules for the design of gas consumption systems. "

- SP 89.13330.2016 - Boiler plants.

- Federal Law No. 123 - "TR on fire safety requirements."

- PP number 390- "On the fire regime."

- NPB 105-03.

Of course, there are still a lot of rules and norms, but these are the basics that will help to properly equip the boiler room in compliance with all fire safety standards.

Why equip a separate boiler house at home?

When arranging the heating system, the owner of the house faces a choice where the gas-using equipment will be located.

Consider the types of boiler rooms.

Boiler rooms may be:

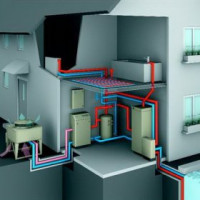

- inside the house - usually provided even at the stage of construction of the house, since the built may not have free space suitable for the parameters;

- on a separate foundation as an extension, along a blank wall and observing the distance to the nearest door and window from 1 meter without capital adjoining a residential building;

- freestanding - are located at some distance from the main house.

The regulations determine that if the power of gas-powered equipment does not exceed 60 kW, it can be post in the kitchen (except for the kitchen-niche), in the kitchen-dining room, other non-residential premises, except for bathrooms and a bathroom.

The minimum furnace volume for 30 kW of power is a minimum of 7.5 cubic meters. m. From 60 to 150 kW require a separate room. The minimum volume of the room is 13.5 cubic meters. m. From 150 to 350 kW. The minimum volume of the room is from 15 cubic meters. m

We are talking specifically about individual boiler houses, that is, with equipment power from 60 to 350 kW.

Rules for the arrangement of premises of autonomous boiler rooms

In order not to get confused in the huge number of regulations, when arranging an autonomous gas boiler for your house or apartment, you can use SP 402.1325800.2018.

This document is included in the list approved by the Ministry of Justice as a voluntary application, but there are several nuances.

A voluntary application document does not cancel the obligation to comply with the rules in the absence or incomplete content of an alternative solution. And meanwhile, the application of this Code of Rules ensures sufficient compliance with TR on the safety of buildings and structures.

Consider its main points that will help us in arranging the premises of a heat-generating boiler in a house or apartment.

So, a separate room of the boiler room, designed to provide thermal energy and hot water, should be at least 15 cubic meters. meters in area and not less than 2.5 m in height when installing a boiler with an open combustion chamber, or 2.2 m with a closed combustion chamber.

The boiler room can be equipped in any non-residential, ventilated room that complies with all standards, including basement / basement rooms, except for bathrooms and bathrooms. At the same time, it is a separate room that is necessary when operating units with a capacity of 50 kW or more, while the total capacity of the boilers (if there are 2) should not exceed the mark of 100 kW.

If you equip boiler room in a private house or an apartment, even in a separate room, you can not install more than two heating units or gas-fired water heaters of a capacitive type.

Ventilation should be of a natural type, the hood is provided for 3 times air exchange per hour and the same supply, which also includes the supplied volume of combustion air. To determine the exact parameters, special calculations must be done. Read more about ventilation of a gas boiler here.

Glazing, and the window opening should be at least 0.03 cubic meters. m from each cube of the area volume of the room, either according to GOST R 12.3.047, should be easily removable.

If you do not know what it is, look at GOST R 56288. That is, it can be polycarbonate, triplex, glass with reinforcement, and so on. Such a right is established with justification for the repayment of pressure during explosions and as ensuring the stability of the building.

The door must be mandatory, and opening outward.

Now about the distances. In the passports of gas-using equipment there is information-recommendations of manufacturers on the location of their devices and the distance to various structures.It is very important to strictly observe them, but at the same time count on the convenience of access to the devices for their management, inspection or repair. Moreover, there are several mandatory fire safety standards.

Walls on which double-circuit type wall units are hung must be fireproof, and the equipment itself should be separated from surfaces, including side ones, by at least 2 cm. The distance is provided by standard fasteners. At the same time, consider the weight of the boiler equipment so that the wall materials withstand a load of at least 35-70 kg.

If gas pressure is planned to exceed 0, 0025 MPa, install in front of boilers and gas boilers stabilizerswhich will align the potentials of gas combustion.

Arrangement of an alarm system

Design decisions on the safety of buildings from gas contamination can be carried out at the design stage. For this, systems with automatic shut-off of gas supply in blocked houses, with gas-powered devices from 50 kW, when boiler rooms are located in basements and basement floors, in multi-apartment buildings, including built-in or attached heat-generating ones, are used.

To determine the presence of combustible gases in the air, regardless of the type of boiler room, an alarm system is provided that works at 3-20% concentration of a hazardous mixture in the air from the lower limit. As a rule, light and sound signaling devices comply with GOST R EN 50194-1.

The automation unit of gas units must block the gas supply when:

- the cessation of burning of the flame at the nozzles without a natural shutdown;

- exceeding the pressure indicators on the sensors or at too low indicators - applies to the coolant;

- if the draft or forced air supply is broken;

- when a power outage occurs - in the case of electrically dependent boilers;

- boiling (overheating) of the coolant.

The automation unit in gas boilers is very important for compliance fire safety.

There are still rules related to grounding, lightning protection and electrics in general.

Now we will consider them in more detail, because they also increase the fire hazard of gas-using equipment.

Power supply and water supply

One way or another, there is electrical wiring in the boiler rooms. This is the supply of light, boiler automation, piezo ignition, lighting, pumping equipment and so on. Its arrangement in the boiler rooms is carried out in accordance with the Rules for the installation of electrical installations.

It goes without saying that when laying the electric cable it is very important to ensure that it passes freely, is accessible for inspection, and does not touch the zones of temperature effects.

It is imperative to provide for the supply of a water supply system to the equipment to ensure the domestic hot water system and the water supply circuit.

Ensuring the installation of water supply systems is carried out according to the standards of SP 55.13330, SP 54.13330, as well as SP 30.13330.

Rules for using house boiler rooms

Autonomous-type boiler plants must be operated in compliance with the rules for using gas-using equipment.

Requirements are standard:

- regularly check the functionality of the equipment;

- Do not use devices with malfunctions;

- Do not store flammable liquids near the units;

- keep children away from equipment;

- annually carry out maintenance of devices with the involvement of specialists from the gas distribution station;

- Do not change or repair heat generators and gas pipelines on your own.

An employee who allows your devices to operate must instruct you on the rules of use for your own safety.

Fire hazard of industrial premises

With single-room and apartment buildings figured out. Now let's talk about heat-generating industrial and warehouse purposes. According to the Federal Law No. 123 TR on fire safety requirements.

To determine the degree of explosion / fire hazard of the object, use the division into classes and categories.

According to PP No. 390, a gas boiler house is classified as a hazardous production facility and belongs to category F5. According to the standards, premises of this type are normalized to the fire hazard category from the most dangerous under letter A, to the least indicated by letter D:

- Increased fire / explosion hazard is A.

- Explosion and fire hazard - B.

- Fire hazard refers to category B - from B1 to B4.

- Moderate fire hazard - under the letter G.

- The reduced fire hazard, which is difficult to attribute to such a gas installation, has a symbol D.

As a rule, it is difficult to coordinate the arrangement of a gas object with a D-subclass, so we will consider boiler rooms from A to G.

The subclass should be calculated based on:

- The type of fuel used.

- According to the degree of fire resistance (I, II, III, IV and V).

- The equipment that is installed indoors.

- Design features of the boiler room itself (hazard class for the design of the gas boiler room C0, C1, C2 and C3). It is determined by article 87 of the Federal Law No. 123.

- Characteristics of ongoing processes.

The subclass is also conditionally determined on the basis of SP 12.13130.2009, NPB 105-03, SP 89.13330.2011, Federal Law No. 123. In principle, it is not necessary to determine which hazard class a particular gas boiler belongs to, if there is a task to simply determine whether it is an OPO.

A boiler room, in any case, is a gas consumption network. OPO is determined by the following criteria:

- The presence of boilers under pressure or temperature indicators of the working environment for 115 degrees.

- If the composition of the gas boiler house contains gas with a pressure of 0.005 MPa.

- A boiler room is a centralized system or installation serving socially significant segments of the population.

The fire hazard class in all respects is determined by specialist designers.

Fire safety of boiler rooms

Industrial buildings are subject to special fire safety requirements. First of all, it is individual and compiled according to the definition of the subclass of the premises at the design and training stage.

But there are general rules. Fire safety requirements for a particular building are indicated in the design assignment, the created project is subject to additional approval.

First of all, it is compulsory to have easily deflectable walling, the size of which is calculated individually, however, it should not be less than 0.05 cubic meters. m for category A and from 0.03 cubic meters. m for category B. The area and thickness of the glazing is determined in accordance with SP 56.13330.

If there is no technical variation in the provision of glazing, there is the possibility of arranging the upper floor of aluminum, chrysotile cement and steel sheets, as well as explosive valves.

The fire resistance of the walls, as well as other internal structures, are determined according to the classification of a gas boiler house according to the category of the room, in compliance with fire safety. In any case, it should be non-combustible materials, which in case of ignition do not contain toxic aggregates.

Doors of boiler rooms necessarily open outside. And the gas pipeline inlet must be equipped with an electromagnetic valve. It is necessary to stop the fuel supply when the safety sensors are triggered and the power is cut off.

Internal water supply is a prerequisite for compliance with the PPB. Fire cabinets are placed near shut-off valves and must indicate on their doors the telephone number of the fire department, as well as the crane number.

In this case, a fire extinguishing system should be installed in such a way that the jets hit, if necessary, at any point in the boiler room.

Features of the boiler room operator

The chief engineer, assigned to the boiler room or another authorized person, approves the PPB and appoints a person responsible for fire fighting, who, in turn, conducts briefing of employees, training and classes on the fire minimum in case of emergency.

Be sure to post for employees the evacuation plan and emergency numbers at visually accessible places.

A daily visual inspection of gas equipment is required.

In no case:

- try to start equipment in which burners and fuel supply devices are faulty;

- carry out the kindling process with idle control and adjustment automation;

- start the units without preliminary purging;

- not use the units for their intended purpose, for example, dry clothes and so on;

- smoking in a room with increased explosion / fire hazard - a special smoking area is equipped separately;

- work in clothing stained with flammable substances;

- ignore the disposal of cleaning material;

- Store flammable vials and cylinders near equipment.

And, of course, access to equipment for children and unauthorized persons is prohibited.

Fire alarms are required to be installed in such premises.

The power supply system of the sensors is necessarily uninterrupted.That is, this is a network connection and a UPS.

Fire fighting equipment for gas boiler rooms

As already mentioned, the location of the inventory necessary to extinguish ignitions, have special designations.

Mandatory presence of powder, foam or carbon dioxide fire extinguishers, designed according to the operating certificate. Sand is stored in metal boxes.

Asbestos fiber, felt and rags are used in the work, and here they should be stored in places protected from fire.

The fire protection kit is contained in special sealed boxes painted in red.

Fire safety of production and storage facilities is ensured by compliance with legislative acts.

Conclusions and useful video on the topic

Ventilation in a boiler room with a gas boiler:

So, we have determined the fire safety standards of house gas boiler houses, how to find out which hazard class a gas boiler house belongs to and what rules apply to them. Of course, these are just general requirements, but when designing a heat-generating premises, it is necessary to study all the regulatory documentation in detail.

Perhaps you have skills in designing gas boiler houses or can you add valuable information to our material? Please share your experience in the comments. There you can ask questions about the topic of the article.

Safety group for heating: device, principle of operation, rules for selection and installation

Safety group for heating: device, principle of operation, rules for selection and installation  Window for a gas boiler house in a private house: legislative norms for glazing a room

Window for a gas boiler house in a private house: legislative norms for glazing a room  The scheme of the boiler house of a private house: the principle of automation and equipment location

The scheme of the boiler house of a private house: the principle of automation and equipment location  How to equip a boiler room in a private house: design standards and devices

How to equip a boiler room in a private house: design standards and devices  Chimney for a boiler room: calculation of height and cross-section according to technical standards

Chimney for a boiler room: calculation of height and cross-section according to technical standards  DIY heating manifold: schemes and assembly features

DIY heating manifold: schemes and assembly features  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements