Atmospheric or turbocharged gas boiler - which is better to choose? Weighted Purchase Criteria

The range of models of gas boilers on the market is quite wide. They differ in functionality, installation method, efficiency. To choose atmospheric or turbocharged gas boiler, you should understand in advance the benefits of each type. It is necessary to find out which type will be optimal for individual heating.

You will learn all about the specifics of the operation of equipment with an open and closed combustion chamber from our article. We will introduce practical qualities, pros and cons of operation. Based on our recommendations, the choice of equipment for arranging suburban property will be significantly simpler and easier.

The content of the article:

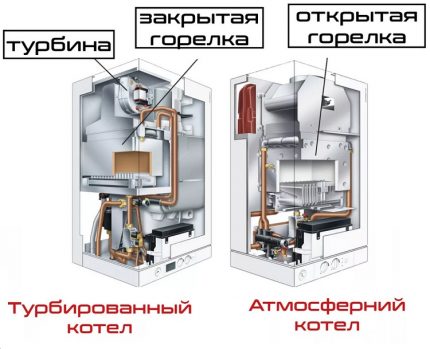

Differences of atmospheric gas boiler from turbocharged

Gas equipment, on the basis of which autonomous heating systems are built, is presented in the market in two versions. The consumer can now purchase or turbocharged or atmospheric (chimney) a type.

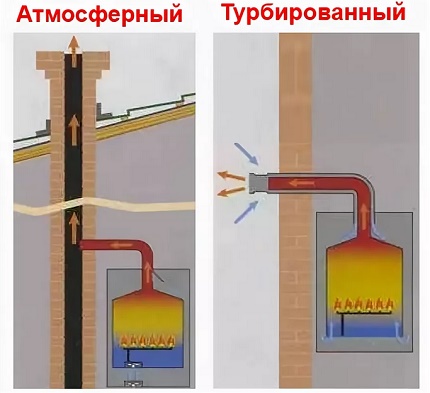

The first group is equipped with a coaxial chimney, as well as a closed combustion chamber. Due to the minimum requirements for the ventilation system, it can be installed in apartment buildings. For the operation of an atmospheric boiler, a traditional chimney is required. It is installed in low-rise private buildings.

In the main working unit of an atmospheric gas boiler, which is an open type, air is taken from the room. The combustion process with the traditional separation of its products occurs openly, therefore, for the installation of atmospheric equipment, a boiler room is set up, separated from the residential area of the house.

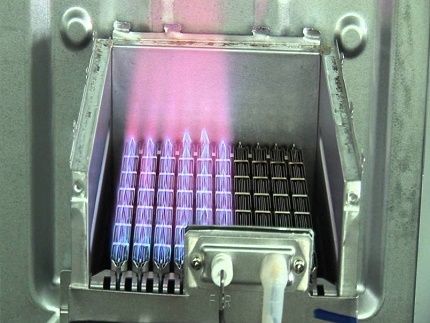

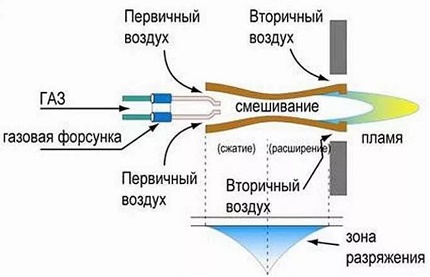

An atmospheric burner is a set of small nozzles through which gas passes under pressure.During combustion, the right amount of air enters the chamber, which enhances the flame. As a result, during the heating of water in the system, an atmospheric boiler spends a minimum of fuel. The smoke is removed through a chimney made of stainless steel.

AT turbocharged The boiler has a closed combustion chamber. Oxygen is driven into the chambers through a coaxial pipe by a fan. Installation of equipment is possible anywhere.

Wall feature turbocharged boiler - the combustion chamber is made of copper, which limits the power to 35 kW. In floor boilers, it is made of cast iron, which can significantly increase power.

Overview turbocharged gas boilers

For heating small apartments and offices, the best choice will be turbocharged gas boiler. It is safe, easy to operate and trouble-free. Stably provides consumers with heated water in the volume they need.

Its advantages over atmospheric:

- if the power is up to 60 kW, the installation location does not matter;

- for combustion, air is not taken from the premises;

- combustion products are removed through a fan to the street through a chimney;

- high efficiency allows you to use less fuel.

Turbine-type boilers are completely safe and can be installed in any room.

Design and operation features

The main structural components of the boiler with a closed burner version:

- gas-burner;

- fan;

- DHW heat exchanger;

- built-in expansion tank;

- heating heat exchanger;

- circulation pump;

- temperature sensors;

- gas valve;

- security systems;

- coaxial chimney;

- electronic control unit.

Installation of such a boiler should be carried out on the outer wall of the house or near the ventilation shaft. Despite the fact that the cost turbocharged models above atmospheric, you can save on the equipment of the boiler room and the installation of a traditional chimney.

Most double-circuit units stop heating the room during the supply of hot water. Contrary to the majority opinion, coolant does not have time to cool down and the temperature in the apartment remains.

Turbocharged boilers are equipped with the "Summer" mode. In this case, hot water is supplied independently from heating systems - This is a good argument in favor of purchasing a model with a closed burner.

Benefits turbocharged boilers:

- air intake for heating is made not from the premises, but from the street:

- sealed combustion chamber;

- no need to install a chimney;

- there is no need to build a boiler room (installation can be carried out in any room);

- compact sizes;

- high efficiency and low energy consumption;

- high performance (on average 10 liters of water are heated per minute);

- automated work and electronic control system;

- high security;

- ease of operation.

Among the shortcomings is the high cost of equipment and parts for repair and dependence on electricity supplies.

Closed burner models

For receipt of heated water in radiators used single-circuit boiler. AT dual circuit models a second heating circuit is provided for preparing hot water.A boiler with a capacity of more than 20 kW will allow heating the room and heating water.

However, the outdoor unit is of low power, it should not be “overloaded”. It is better to heat water with a geyser. According to the standards, it is allowed to put two separate boilers in one boiler room: wall-mounted and floor-mounted. One of them will supply sanitary water, and the second will be a coolant.

Double-circuit models are divided into boilers with bithermic heat exchanger and separate. The first is used for heating and DHW. Its disadvantage is sensitivity to bad water. It quickly forms scale and decreases productivity.

During operation, it is recommended to use descaling powder. A separate heat exchanger performs the same functions as bithermicbut less sensitive to water.

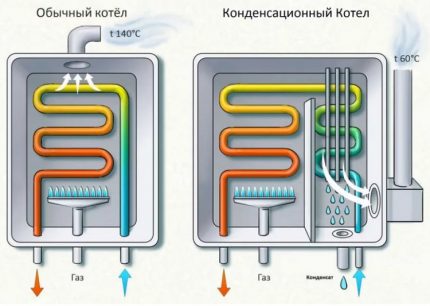

Condensing boilers, in addition to the usual generation of heat, additionally use the energy released during operation of the equipment during condensation of water vapor. In essence, condensation is collected by these models in order to give its heat to heating appliances. Such boilers can save up to 17% of gas, and their efficiency reaches 108%.

You say that the efficiency of any type of heating equipment can not exceed 100%? Maybe that is confirmed by condensation models. They partially use twice the energy released during the combustion of one portion of fuel.

Overview of atmospheric gas boilers

The main characteristics of atmospheric gas boilers:

- power - from 20 to 60 kW;

- large dimensions and weight;

- productivity - up to 30 l / min;

- average efficiency indicator - 79-92%;

- electronic control panel.

This model is equipped with an open combustion chamber. Oxygen is taken from the room where the equipment is located, and combustion products are discharged through a chimney. A leak in the combustion chamber leads to the fact that part of the gases enters the environment and can cause poisoning.

Therefore, for atmospheric boilers, a special room with good ventilation is equipped.

Choosing a place to install:

- the design is installed in a technical building;

- for powerful and dimensional models, a building with a foundation is required;

- to ensure sufficient draft, close proximity of the chimney with minimal bending is necessary;

- It is important to provide communications for the output of a coaxial chimney.

The operation of the atmospheric boiler is based on heating the heat exchanger material with a gas burner. It then transfers the received energy to the heat carrier or water prepared for consumption.

Burner design:

- nozzle;

- head;

- air regulator;

- ejection a tube.

With a partial part of the gas flows directly, and the other part with air. At full - before getting into the combustion chamber, there is a complete mixing of gas with air. In the CIS countries, there are no models with full mixing.

Burners are one and two-stage, with smooth switching of the fuel supply speed and modulated. Cost savings depend on the complexity of the design. Some models may use diesel. But the price of such boilers is much higher.

Burners included CO2 level sensors and flame. If the draft is insufficient, the flame may be extinguished, which will lead to gas contamination of the room.A similar problem is observed in makeshift designs that are remade from solid fuel boilers.

Advantages of atmospheric gas boilers:

- stable operation even with low gas pressure (fate should be that in this case the fuel supply elements fail more quickly);

- for efficient combustion of the mixture an additional air supply is not required;

- silent work;

- ease of operation.

There are significant disadvantages. The most important is the possibility of carbon monoxide leakage and fire. Therefore, boiler equipment with an open type of gas burner requires a separate room (inability to install in apartments).

Types of atmospheric gas boilers

Heating equipment differs among themselves:

- dimensions plus weight directly related to dimensions;

- power;

- Efficiency.

The maximum power of wall-mounted models of atmospheric boilers is 36 kW. This indicator is due to design features.

To select the optimal power, you should take into account the area of the room and the factors of possible heat loss (windows, cold floors and walls). It is recommended to choose a boiler that can heat the area 25% more than the actual one.

In addition to power, when choosing a boiler, you should pay attention to efficiency. This indicator shows how much energy is required to heat the water, and how much it burns. The average performance for atmospheric boilers is 80-90%. More expensive models provide maximum effect - up to 97%.

In condensation boilers, the efficiency is 100%. The fact is that the exhaust gas is heated to 110 ° C. AT turbocharged aggregates, this figure is at 55 ° C. In condensation - 30 ° C.

Floor and wall types of equipment

The floor design is characterized by high weight - up to 100 kg. It requires a lot of space to install it, and installation is time-consuming, complicated and expensive. Most floor-mounted atmospheric boilers do not heat water for supply to mixers. During work floor unit it makes a lot of noise, and the chimney requires regular cleaning.

Positive sides:

- high power

- durability;

- lack of electronics.

Wall-mounted heaters are smaller and lighter (up to 50 kg). Such boilers are mainly double-circuit. The model is easier to install and does not take up much space. You can position the boiler anywhere in the room. Wall-mounted atmospheric boilers single-circuit and bypass.

The disadvantage is wall boiler Depends on the electronics. If something burns out, you will lose hot water and heating. Installation of boilers is carried out mainly in small apartments and houses.

So what to choose?

Turbocharged models use air from the street that enters through a coaxial tube. Unlike atmospheric boilers, they can be installed in the kitchen, in the bathroom and other residential premises. This is the best option for heating an apartment or oversized house.

Choosing between turbocharged and atmospheric boiler, several factors speak in favor of the first:

- no need to allocate space for the boiler room, which attracts owners of small houses;

- can work absolutely autonomously;

- optimal for servicing small-sized objects.

Atmospheric boilers are installed when:

- need to burn a large building;

- the probability of using several types of fuel is necessary;

- there is no possibility of connecting to the mains.

In private houses equipped with a brick chimney, you need it screw up acid resistant pipe. If this is not done, then condensation will destroy the pipe.

In an atmospheric boiler (convection), an open chamber is provided for burning gas. This model is connected to a standard chimney. Air is taken from the room in which the equipment is installed.

High requirements are set for the installation of equipment with an open combustion chamber. Atmospheric-type boilers are not allowed to be installed in houses, the number of floors of which exceeds 9 levels.

AT turbocharged the combustion chamber is hermetically sealed. Waste collection is forced; Pressure is pumped by a turbine or fan. Air from the room where the equipment is installed is not burned.

According to the data sheet, the boiler can be located in the bathroom, in the kitchen, bedroom, next to the meter. It can even be hidden in a specially equipped niche. Smoke discharge carried out through a coaxial chimney.

Conclusion: the main difference between an atmospheric gas boiler and turbocharged consists in the forced intake and exhaust of the exhaust air required as an oxygen source for the operation of the burner.

How to choose a boiler?

At choosing a gas boiler analyze three main parameters: all technical specifications, reliable and trusted manufacturer, cost. Be sure to analyze the room in which the equipment will be installed. The first thing you should pay attention to the power and functionality of the equipment.

Criteria for a wise choice

Important features:

- Performance. The calculation is made after analyzing the area of the room and the possible heat loss.

- The number of circuits served. If it is necessary to heat the room and hot water supply, choose a dual-circuit boiler with a pair of heat exchangers. If DHW not necessary then enough single-circuit boiler. In new dual-circuit heating devices, the Winter / Summer mode is provided.

- Material of which the heat exchanger is made. For the primary circuit, steel or cast iron is used, and for the secondary, copper and aluminum. The service life, thermal conductivity and cost depend on the material.

- Automation. It is provided in the bypass turbocharged the boiler. There are two types: standard and weather dependent. In new models, remote control units are integrated. The model can be additionally equipped with a remote alert. Gas consumption depends on the number of automation functions.

The best models of gas boilers are produced by German companies. In second place in popularity are Italian and French products. Russia also began to supply competitive boilers of low cost.

The most reliable boilers from Baxi, as well as Vaillant Turbo TEC, Viessmann, Vaillant Atmo TEC. In second and third place are models from Neva Lux and Arderia. Low reliability and build quality of Korean products from Navien, Hydrosta, Daewoo and Kiturami.

Installation Requirements

The highest demands are placed on the installation of atmospheric boilers. Installation and connection is carried out only by representatives of the gas company, with whom an agreement is concluded for further maintenance and inspection of equipment. All connecting nodes must be made perfectly, extremely tight.

Turbocharged models are not so demanding, but a hand-held connection is also not particularly recommended. Especially if the fault of an inexperienced artist water gets into the gas pipeline. There is an important condition - the perfect removal of chimney ducts to the street.

Conclusions and useful video on the topic

Video # 1. Heat engineering recommendations for future buyers of gas heating equipment:

Video # 2. Expert opinion: is it possible to connect a boiler with a closed burner to a conventional chimney:

Video # 3. Valuable recommendations for selecting the power of a gas boiler:

Choosing between turbocharged and atmospheric boiler, it is necessary to take into account the structural features and nuances that are characteristic during operation. You should definitely familiarize yourself with them and the technical characteristics of a particular model before making a purchase. We hope that the information provided by us will provide effective assistance.

Want to talk about how to choose a gas boiler for arranging a suburban property or apartment? Share what type of boiler you prefer, reveal the secret why. Please leave comments in the block below, post a photo on the topic of the article, ask questions.

What is better double-circuit or single-circuit gas boiler: features of the device and operation

What is better double-circuit or single-circuit gas boiler: features of the device and operation  Wall or floor gas boiler - which is better? Arguments for choosing the best equipment

Wall or floor gas boiler - which is better? Arguments for choosing the best equipment  How to choose a gas wall-mounted double-circuit boiler: what to look at + what the market offers

How to choose a gas wall-mounted double-circuit boiler: what to look at + what the market offers  How to choose a dual-circuit floor gas boiler: what to look at before buying?

How to choose a dual-circuit floor gas boiler: what to look at before buying?  How to choose the best gas boiler: an overview of the criteria for choosing the best unit

How to choose the best gas boiler: an overview of the criteria for choosing the best unit  Which is better and more profitable - a gas or electric boiler? Arguments for choosing the most practical option

Which is better and more profitable - a gas or electric boiler? Arguments for choosing the most practical option  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements