Water flows from a gas boiler: what to do if heating system equipment has flowed

When you see that water is flowing from a gas boiler, do not put off the solution to this problem in a long box. After all, you don’t want to change the whole boiler because of a small crack in the heat exchanger, do you? We must say right away that coolant leaks occur for other reasons and in other places. How to detect and eliminate them is the topic of our article.

We will tell you by what signs you can quickly identify a leak. Let’s show you which structural components are most susceptible to loss of tightness. Our recommendations will help to quickly identify the cause, to eliminate it, without waiting for irreparable damage.

The content of the article:

Water Leak Locations

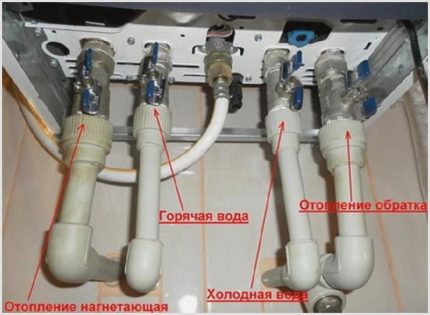

Leaks can occur all along the water. If a dual-circuit gas boiler flows, the problem may be in the following nodes:

- heat exchanger;

- pipes;

- expansion tank;

- places of detachable connections.

The level of complexity of the upcoming repair largely depends on the place of the water leak.

The easiest way is to repair leaks at the joints. It is more difficult to repair a leaking pipeline inside the equipment. The most laborious process is repair or replacement of the heat exchanger.

Leaks must be repaired as soon as possible after they occur. Loss of coolant can lead to automatic shutdown of the boiler.

An attempt to compensate for the loss of coolant by periodically adding a new portion is fraught with accelerated wear of the boiler. Water is saturated with oxygen, which accelerates the corrosion of metal components, which reduces the life of thermal equipment.

How to determine if the boiler is leaking?

A coolant leak reduces the hydraulic pressure in the heating system.We must say right away that pressure can change for other reasons, for example, in connection with a change in the density of water. But if the pressure gauge needle stubbornly falls down or a notification about the lack of water in the system is displayed, it is necessary to check for leaks.

Inspection of problem areas is carried out: first of all, detachable connections, including cranes. But not always the place of the leak can be determined visually, because coolant will not necessarily flow in a continuous stream, flooding the floor. More often than not, it just drips. Getting on hot surfaces, drops evaporate.

Therefore, you need to pay attention not only to damp places, but also to traces of drips, spots of rust. It is better to look for leaks with a flashlight, inspect hard-to-reach areas with a mirror. Place napkins under the possible leak points. Their wetting will serve as confirmation that there is a coolant leak.

If only a pressure drop indicates a leak, it may not be in the boiler, but in other elements of the heating system, including radiators, which are also subject to inspection.

It can be done as follows: water is drained from the circuit and air is pumped using a compressor. It will exit the leak with a characteristic noise. If the pipes are laid under tiles or in concrete floors, you will have to use a phonendoscope to hear the sound of air coming out. Also in this case, a leak search can be performed using a thermal imager.

What to do with condensate?

A pool of water under the boiler is not necessarily a sign of leakage. Perhaps this is condensate, that is, water formed during the condensation of steam.

When the boiler starts, air containing moisture enters its combustion chamber. When a gas-air mixture is burned, this moisture passes into hot steam much faster than the heat carrier heats up. Vapors come into contact with the still cold surface of the heat exchanger and settle on it in the form of condensate.

After heating the coolant to 60-70 degrees, the condensate evaporates. To speed up this process, when starting the boiler, you can set the adjustment knob to the appropriate division, and then, if necessary, reduce the heating to 40-50 degrees.

Condensation during a long-running boiler with a coolant temperature above 60 degrees can indicate an incorrect organization of the heating system. It is worth checking once again whether mistakes were made during the design and installation of the harness.

Do not underestimate the problem. condensation, since prolonged exposure to an acidic medium on metal surfaces leads to their corrosion. Wet surfaces attract soot to themselves, because of which the thermal conductivity deteriorates and the efficiency of the boiler decreases.

Condensation also settles on the internal surfaces of insulated chimneys, which leads to accelerated pollution and wear. Insulation of the chimney helps to solve the problem.

Flowing through threaded connections?

The heating circuit of the boiler is closed. Heated coolant flows from the heat exchanger tube to the supply pipe and then to the radiators. The coolant returns through the return pipe, entering the heat exchanger again and then continuing to circulate in a circle.

Pipes of the heating circuit are connected to the supply and return pipes using threaded (detachable) connections using connecting parts - flanges with union nuts, or otherwise American.

Threaded connections are sealed with elastic, heat-resistant, ring-shaped seals. If they are worn or if installed incorrectly, water leakage occurs. Poorly tightened nuts lead to the same consequences.

If you see water dripping at the threaded joint, you should first try to tighten the nut. Excessive zeal is useless here, since if the nut is tightened too much, it may break. If water leakage continues after tightening the nut, the seal must be replaced.

Switch off the gas and water supply in advance, drain the water from the heat exchanger. Unscrew the union nut, replace the gaskets and reinstall the nut.

Manufacturers of heating boilers seal detachable joints with gaskets made of rubber, silicone, paronite or other flexible materials. They are easy to use, durable and always commercially available. Often come with locks. When choosing gaskets, the size of the thread is taken into account.

You can also use sanitary flax as a sealant. Regardless of the presence of leaks, the seals change during each disassembly of water lines.

The problem in the expansion tank

The volume of water filling the heating circuit changes depending on the level of heating. With increasing temperature, the volume of water increases, which entails a change in hydraulic pressure inside the closed heating system.

At this moment, the elements of the heating circuit would undergo an increased load, fraught with their breakdown. But this does not happen, as the design of the boiler is supplemented by a security system, including an expansion tank, which accepts the resulting excess water.

For installation on heating pipelines use open and closed expansion tanks. Open tanks are installed outside the boiler rooms, for example, in attics, and are equipped with a whole system of pipes for connecting expansion, circulation, signal, overflow pipes.

All models of wall-mounted both double and single-circuit boilers are equipped with built-in expansion tanks. They belong to the closed type, have only one pipe and two internal cavities separated by a membrane. To ensure regulatory pressure in a broad tank, in its upper cavity there is air or an inert gas, for example, argon and there is an air valve with a nipple.

The excess coolant through the pipe enters the lower cavity. The membrane bends, air is compressed in the upper cavity, and the coolant occupies part of the internal space of the expansion tank.

Excess coolant generated during heating is discharged safety valve the boiler itself or the heating system. If necessary, the liquid is replenished through the boiler feed valve.

In open and closed expansion tanks, leaks occur at the places of threaded connections of pipes with pipes. To eliminate them, tighten the union nuts or replace the gaskets, as described above.

The metal bodies of the expansion tanks are subject to corrosion due to the presence of oxygen bubbles in the water mass. Corrosion leads to the formation of fistulas (holes), which become the place of leakage of the coolant.

The more often you have to pump a new portion of water into the system, the higher the risk of damage to the body of the expansion tank and other metal components. If there are fistulas, the tank is changed to a new one.

Leakage through safety valve

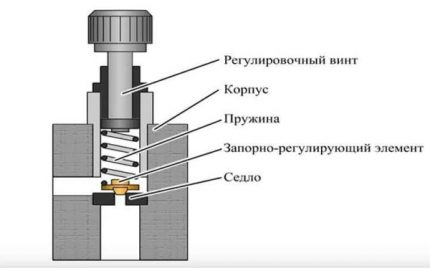

An important element of the security system is the safety valve, which is necessary for “securing” a closed expansion tank.In boilers for individual heating systems, spring-loaded safety valves are usually installed.

A metal spring is located in the body of such a valve, which presses on the stem, and it, in turn, holds the support plate in the position when it is firmly pressed against the seat.

If, with increasing pressure in the heating system, the expansion tank for one reason or another does not cope with its functions, the coolant increases the pressure on the plate. The spring is compressed at this moment and lifts the plate above the saddle. Through the hole formed, the excess coolant rushes into the drainage pipe and then into the sewer.

If the expansion tank is not selected correctly and its volume is insufficient to accommodate all the incoming water, rupture of the membrane may occur and the water will fill the entire upper cavity. With a further increase in pressure safety valvethrough which there is a removal of the formed excess coolant.

The safety valve also activates if the diaphragm is torn due to wear, air leaks through a faulty nipple, or malfunctions in the control automatics

If the connection of the valve pipe to the drain pipe is not tight enough, the coolant will not be in the sewer, but on the floor. To prevent this from happening, during a technical inspection, pay attention to this area and, in the presence of the slightest leaks, perform sealing.

Be sure to determine the cause of the valve. If necessary, install a new expansion tank, taking into account the volume of coolant in the system, change a worn membrane, a faulty nipple or a tank assembly, solve problems with settings and controls.

The emergency situation for the heating boiler is standard for the safety valve itself, because it is needed in order to reduce the damage from the consequences of the accident. But the valve itself may fail, causing the coolant to leak.

Most often, the breakdown is associated with a spring, which constantly experiences stress and, as a result, loses its elasticity, which leads to leaks even during normal operation of the system. The defective valve is replaced with a new one.

When choosing a valve, its technical parameters are taken into account:

- nominal diameter of a branch pipe opening (DN);

- threaded connection size;

- set pressure.

The requirements for safety valves for heating systems are regulated by GOST 12.2.085-2002.

But what if the gas boiler leaks due to a breakdown of a newly installed valve? This happens when a grain of debris gets in between the plate and the saddle, for example, rust from an expansion tank. In this case, the valve is removed, washed under running water and installed in place.

The valve is installed so that the spring is vertical. An arrow is shown on the body, indicating the direction of flow of the coolant. To seal threaded joints, heat-resistant elastic gaskets or sanitary flax are used.

Damage to the heat exchanger and pipes

If the heat exchanger of the gas boiler is flowing, the wall may have burned out, a crack or fistula has formed. According to the material of manufacture, heat exchangers are divided into copper, steel, cast iron.

Cracks in the metal are formed under the influence of thermal stress and hydraulic pressure. Corrosion processes lead to the formation of fistulas.Repair is carried out by soldering.

The main stages of the process:

- heat exchanger dismantling;

- cleaning and degreasing the area around the leak;

- soldering using flux and solder;

- test;

- installation.

When leaking in an easily accessible place, complete disassembly heat exchanger for repair not required. It is enough to remove the casing, shut off the gas and water, disconnect the electric wires, drain the rest of the water.

The place of soldering is cleaned and degreased with a solvent. Soldering is carried out using a soldering iron or gas burner. The heat exchanger is installed in place and communications are connected to it.

Tests are carried out by crimping. The circuit is filled with water, the pressure is increased to a test value and it is controlled using two pressure gauges for at least 5 minutes. If the pressure drop is not fixed, during visual inspection of leaks was not noticed, the repair can be considered completed.

In case of severe damage, repair of the heat exchanger is not practical. They just change it to a new one. It is also impossible to solder many Chinese-made heat exchangers, as they are made of thin-sheet alloys that cannot withstand soldering.

Conclusions and useful video on the topic

Methods of sealing threaded joints in individual heating systems using various materials:

Elimination of leakage from the overpressure valve in a double-circuit gas boiler:

In heating boilers, coolant leakage can occur in different parts of the heating and domestic hot water circuits. It is not difficult to replace the seal on threaded connections yourself. To eliminate leakage through the fistula of the heat exchanger, skills of a plumber and a welder, considerable experience, tools will be required.

Repair of damaged elements is not always possible, sometimes their replacement is more appropriate. With the prompt elimination of leaks, negative consequences do not occur and the boiler is operated in the previous mode.

Please leave comments, ask questions, post photographs on the topic of the article in the block below. Tell us if you had to repair the heating unit, share the technological nuances known to you. It is possible that your advice will be very useful to readers of the site.

What to do if the gas boiler blows in the wind: causes of the boiler attenuation and methods for resolving the problem

What to do if the gas boiler blows in the wind: causes of the boiler attenuation and methods for resolving the problem  The principle of operation of a dual-circuit gas heating boiler and features of its connection

The principle of operation of a dual-circuit gas heating boiler and features of its connection  Layout of a gas heating boiler: general principles and recommendations

Layout of a gas heating boiler: general principles and recommendations  Connecting a double-circuit gas boiler to the heating system: requirements and norms + installation steps

Connecting a double-circuit gas boiler to the heating system: requirements and norms + installation steps  How to increase the efficiency of a gas boiler with your own hands: the best ways to increase the efficiency of the boiler

How to increase the efficiency of a gas boiler with your own hands: the best ways to increase the efficiency of the boiler  Conord gas boiler malfunctions: common breakdowns and solutions

Conord gas boiler malfunctions: common breakdowns and solutions  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Hello! Please tell me what could be the problem. Faced such a problem: the tap in the bathroom knocks out on the ground floor (straight thread breaks). Repeated for the second time. All the rest stand still.