Brick stove for the home: guidelines for choosing the optimal type and examples of routines for independent masters

The hearth is the heart of buildings not connected to centralized networks. It generates the necessary heat for life and gives energy for cooking. The microclimate in the construction, and its service life itself, depend on its productivity and efficiency, and these are very important factors for the operation of the unit, agree?

The article we presented details how to correctly build a brick oven for a home. The construction schemes of the home are given, the technological nuances are thoroughly analyzed. We offer carefully selected, meticulously verified, practice-confirmed information on the selection and arrangement of brick stoves.

Beginners and owners of suburban property who want to monitor the work of hired craftsmen will be helped by the information we have proposed, based on construction requirements. Great help in mastering the material will be photo images and video guides.

The content of the article:

Brick oven design selection

The structural abundance of brick kilns is not easy to figure out. However, the owners of suburban real estate who want to equip the house with a brick assembly, this difficult question should be studied. It is better to determine in advance the optimal option for the purpose and device than to rebuild and modernize.

Brick stoves are divided into types according to the following aspects:

- Destination.

- Type of gas movement.

- Performance.

- The frequency of the furnace.

- Geometric data.

Ideally, a stove that is perfect for you personally is selected according to two or three of the most important criteria. We will analyze what should be attributed to aspects that are significant in your opinion, which will become the basis for choosing the optimal brick aggregate.

Destination classification

By purpose, brick stoves for private households are divided into three groups:

- Heating. Brick structures that fulfill the only duty - the supply of heat to the serviced premises. Heated rooms can be no more than three. Moreover, the walls of the stove should, if possible, serve as part of the interior partitions.

- Heating and cooking. Stoves equipped with both a heat-generating surface and a hob. Brick slabs equipped only with a cast iron hob also belong to this category.

- Special purpose. These are units designed to solve highly specialized tasks: baking bread, preparing a bath for taking procedures, drying clothes or finishing indoors. This group includes furnaces for garages, greenhouses, workshops.

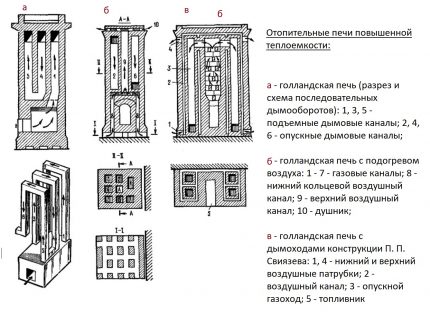

Typical representatives of the first group are Dutch women, thin-walled stoves built in frames, tiled and Markov designs. Characteristic of the second group are Russian stoves, stoves with and without a water circuit, as well as kitchen centers.

In the third group there is an abundance of variations. However, if we take into account structures made of bricks, then the stoves mainly prevail. Although they can be metal, but with a brick lining - the lining of the firebox with refractory bricks.

Brick stoves are built from a material with high heat capacity and relatively low thermal conductivity.Simply put, heating, cooking and bath stoves made of bricks are heated more slowly than metal ones, but they also retain much longer heat.

The low thermal conductivity of the brick is also good because, despite the high temperature inside the furnace, reaching 500-700º, the external surface of the brick structure is heated only to 95-100º. This superior property meets both hygiene and safety requirements.

Dividing into species by gas movement

The priority qualities of the material weightily complement the design features of the furnaces. To increase the heat capacity, smoke channels and chambers are provided in them, through which smoke circulates for a while before leaving the furnace through the chimney and into the atmosphere.

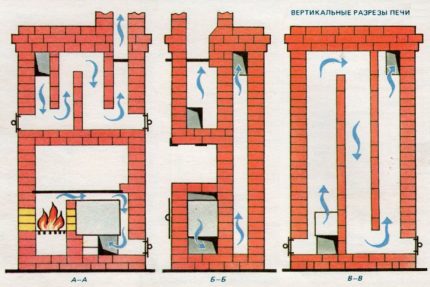

The movement of gases through the smoke channels - smoke exaggerated exaggerated will be described as follows:

- Flue gases of high temperature, rushing from the furnace upwards, meet the stove overlap on their way.

- Having stumbled upon an obstacle, gases flow into vertical and horizontal channels and ply them, giving off heat to the walls of the furnace.

- The flue gas that transferred heat to the brick cools down, descends to the exit to the chimney, and exits through it out into the atmosphere.

Note that in furnaces with horizontally oriented channels, gas cooling is faster, because gases move more slowly along them than along vertical paths. As a result, heat is distributed unevenly over the heat-releasing array, most often it accumulates at the exit of the furnace.

Therefore, in the stove business brick constructions with vertical smoke circuits prevail. In them, the movement of gas occurs due to the action of natural laws. They are connected to each other or to the channel exiting the firebox with short horizontal jumpers.

The disadvantages of structures with vertical smoke circuits include a noticeable difference in the heating of the part of the furnace located above the channel adjacent to the furnace and the channel combined with the chimney. In units with horizontal revolutions, the bottom of the stove warms up better, at the top they are colder, which is better according to sanitary standards.

If you decide how and what kind of brick oven to build in the house, you need to consider that the smoke ideally moves vertically in an ascending or descending direction, depending on the design. Only under the pressure of the gases accumulated above or under the overlap, does it flow into the next revolution.

The presence in the design of channels of too much length, even if vertically oriented paths predominate over the area, is also not the best option. As a result of too long circulation, the gas cools too much, which, like in the case of horizontal revolutions, threatens uneven heating.

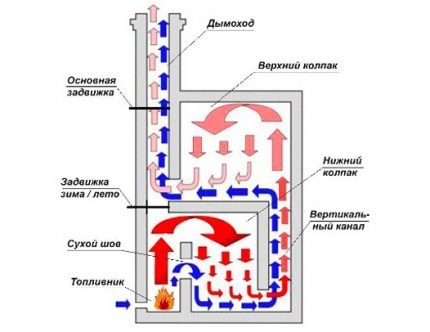

The disadvantages of uneven distribution are to some extent eliminated in bell-type furnaces. In this group of furnace designs, traditional separate channels are combined in one chamber - a hood located above the firebox.

Gas, flowing out of the furnace into the hood through a narrow hole, hits the upper ceiling of the stove. Spreading from the blow in different directions, it falls down, from where it is pulled into the chimney under the influence of natural traction. The scheme with a cap allows you to evenly distribute heat, but this group also has drawbacks - the upper part heats up more strongly than the lower one.

In terms of heat capacity, bell-shaped designs are ahead of stoves with revolutions. Therefore, the former choose to equip large area houses, the latter for dachas and small buildings, for heating of which an unnecessarily productive unit is not needed.

Brick Performance

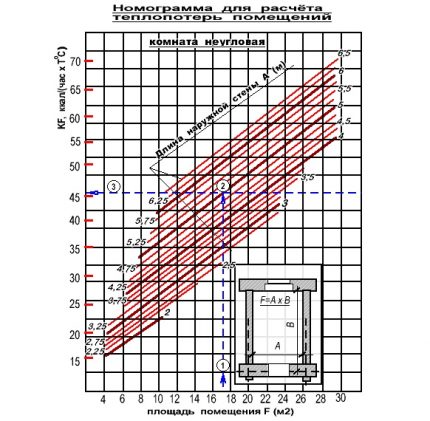

The stove must cover the heat loss of the treated rooms. Therefore, its power is directly related to the thermal characteristics of the rooms. They are found by adding losses through walls and floors with ceilings, through door and window structures, through ventilation system.

Calculation of heat loss will make it possible to determine the productivity of the furnace, which should be slightly greater than the calculated value, but not more than 15%. If the capacity of the brick aggregate is greater than the specified limit, you should choose another design.

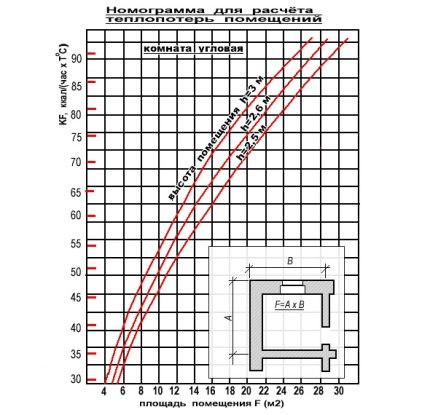

To facilitate the process of choosing the most suitable brick oven for masonry in a low-rise building, nomograms have been developed. The graph below, which simplifies calculations for the selection of a stove, was created for rooms with one external wall.

Using the presented nomogram is extremely simple. On the abscissa axis of this graph, it is necessary to postpone the point # 1 - the size of the area of the room, which we are now dealing with heat loss. It should be pulled up to the intersection with the inclined line, this is point # 2.

Then, to the left of point # 2, draw a horizontal line to the point of intersection with the ordinate axis. This is point # 3, the coefficient of the outer fences, we denote it by KF. We multiply the coefficient by the average temperature observed in the region during the winter months (we find it in Construction Climatology).

For rooms with two external walls, another nomogram has been developed. To work with it, in addition to the area of the room, information about the height of the ceilings will be required.

To calculate the thermal characteristics of furnaces with closed surfaces facing the rooms, correction factors are used. If one or two side surfaces are closed, the resulting values are multiplied by 0.75.

Frequency of the furnace firebox

According to the frequency of fuel loading and the specifics of its processing, the stoves are divided into two groups:

- Periodic action. These are stoves in which it is required to load firewood and carry out the furnace several times a day. Due to the fact that the temperature in their fireboxes sometimes reaches 1000º, they differ in thick walls. Usually they are placed in ¾ or in 1 brick.

- Continuous burning. These furnaces are not designed to accumulate heat, therefore they have thin walls folded into a half brick or в. The fuel embedded in a typical mine firebox in such stoves smolders for about a day, portionwise releasing a small amount of heat.

Since continuous burning requires a regular supply of a large amount of oxygen, in the summer cottage similar structures did not particularly take root. True, they "excellently" cope with the heating of large private houses, industrial and commercial buildings with their own boiler and mechanical ventilation.

Periodic combustion stoves are selected, focusing on the priority number of furnace processes per day. In mid-latitudes, the stove should be heated twice in 24 hours.

As much in the northern regions, but the furnace in the north is increasing in duration. In the south of our country, heating is enough once.

Geometrical parameters of the unit

In terms of the majority of cooking centers and heating stoves resembles a rectangle. Moreover, hobs are mostly rectangular, and combined structures are square or rectangular.

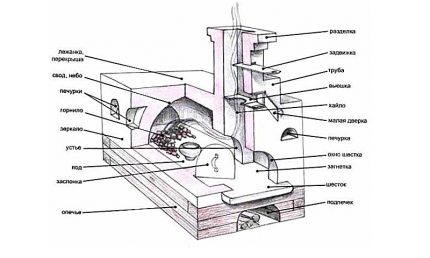

In Russian versions, designs are usually supplemented by attached brick beds, sleeping places on the upper ceiling of the furnace. Not only stoves are attached to the stoves, but also attacks, and stoves for drying things, harvesting mushrooms for the future and similar purposes.

Heating stoves are rectangular, square and even round, the so-called Irish. Round varieties are constructed in a metal frame, thanks to which it becomes possible to lay in ¼ brick. This ensures durability and increases heat transfer.

Thick-walled models include Russian stoves and heating units, folded with a wall thickness from half to a whole brick. All structures constructed with wall thickness up to ½ brick belong to the class of thin-walled.

If you think how to build an effective brick stove in a house intended for permanent residence at the lowest cost, then it is better to prefer a rectangular or square heating and cooking structure. The construction of a cooking center and a heating Dutch is quite acceptable.

For giving, a miniature square or round thin-walled stove is quite suitable, if cooking is not supposed. Among the combined options, one of the small varieties of the Russian or Swedish stove will be optimal.

We also recommend reading an article on how to build a mini Russian stove with your own hands. More details - go to the link.

Three options for laying the stove with orders

The construction of a brick stove is quite expensive. The most modest option for a small cottage on average can cost 150 thousand rubles. Therefore, there are many who want to build a simple stove in a private house without stove-makers, that is, with their own hands. In the implementation of this idea, we are happy to help independent craftsmen.

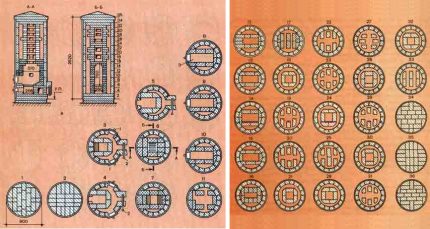

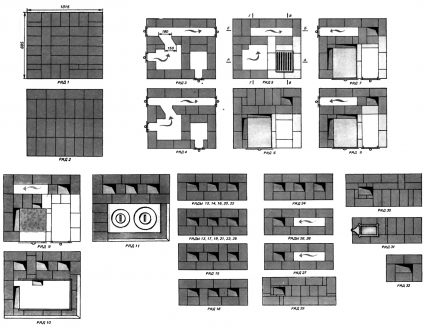

We will make a reservation right away that only the procedure for constructing a furnace massif, the main part of the structure with functional chambers and channels, is understood in the orders proposed for consideration.

We do not consider the construction of the foundation, since its main postulates are given in another article on our website. We do not disassemble the laying of the chimney within the attic or attic and above the roof. We do not offer projects and orders of complex two-story heating structures, but present the simplest schemes.

Option # 1: Russian stove with a high stove bench

This universal furnace construction is being built in the middle and northern latitudes of our country. You can heat it once / twice depending on weather conditions. If the fuel is loaded only once a day, then the heat transfer of the unit will be 2100 kcal / hour. When carrying out two furnaces, the efficiency will increase to 3000 kcal / hour.

When performing a single firebox per day, the lateral and rear surfaces of the array are allocated in the amount of 1200 kcal / hour, the overlap will emit 500 kcal / hour, and the front wall is 400 kcal / hour. Two furnaces will increase the indicated indicators to 1750, 700 and 550 kcal / hour, respectively.

As in most Russian ovens under the hearth, the outer edge of the hearth, on which the dishes with food are exposed before being sent to the mouth or before being removed, has a notch. It is called a subfire, intended for storing devices for caring for the structure.

Productivity allows you to perfectly process an area of up to 30 m². A feature of the described design is the presence of vaulted ceilings over the technological holes. If there is any doubt that they will be executed perfectly, you can fold them without arches, just rectangles.

The starting first row is laid out solid, for its construction it is generally recommended to use cement or lime mortar. The next three rows from the 2nd to the 4th are built in the form of a well, but with a hole for the heel, located on the front side. In each row, the brick is laid with dressing, i.e. with a run of seams.

In the 5th row, the laying of the arch begins, which is placed on a figured formwork arranged from a board or scraps of plywood. To support the elements of the bricks, heels are choked. Then two rows 6 and 7 are laid with a dressing, at the same time a vault is being erected. During the construction of the 8th row, the arch is closed.

The construction of the furnace in rows 8, 9, 10 is performed in one brick. In the 11th row, the cold stove is closed. Sand is poured on top so that a bias is formed towards the rear wall of the stove.

In the 12th row, the hearth is made - a continuous brick surface. Lay it right on the sand. Since this part of the furnace will come in contact with direct fire, it is better to use refractory bricks in construction. If under does not go perfectly smooth, then it is leveled by adding sand from above and grinding the surface.

From the 13th to the 16th row, the crucible is laid. The construction is done in ¾ brick. Elements are laid with dressing, but the solution is not used. The brick is clamped at 45º to make it possible to arrange castles.

In the 17th row, the next arch is laid, the mouth and back wall of the stove are formed. As a result, at the same time, the basis for the construction of the cooking chamber is arranged. It is being erected with a brick placed on the edge. Heels are choking.

In the 18th row, they begin to erect the walls of the stove. The space between the cooking chamber and the heating part is filled with sand with broken bricks. In the 19th, the vaulted opening was again performed, this one is located above the sixth, and behind it the mouth of the stove is arranged.

In the 20th row, the masonry is made so that the walls are aligned, and the hole above the sixth is reduced. From this series begins the erection of an overtube. In the 21st row, the construction is carried out in the same way as in the 19th.

The vault closes in the 22nd row. To the right of the annulus, the base of the chamber is designed to collect soot. On the same side, bricks are squeezed for the construction of a view that blocks the chimney to preserve heat in frosty times.

From the 22nd to the 32nd row, an overtube is built, view valves are installed, a chimney channel with a section of 26 × 26 cm is built.

Then the chimney is constructed and an additional damper is installed. The frame for the shutter is made of a metal corner or strip 3 mm thick.

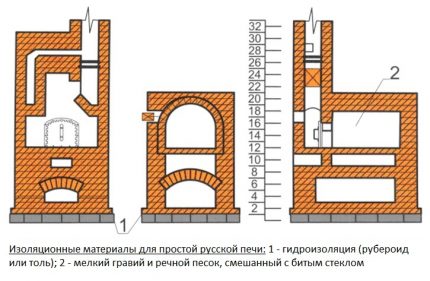

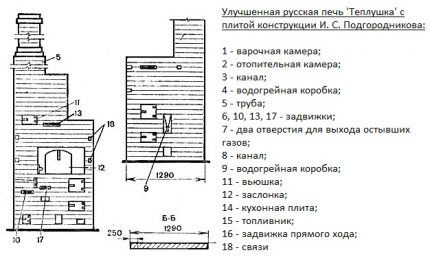

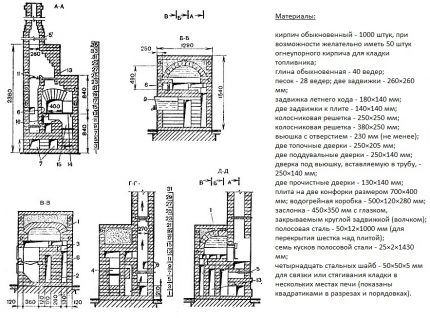

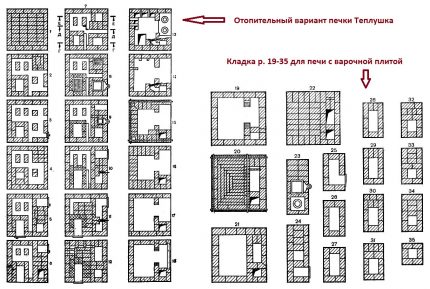

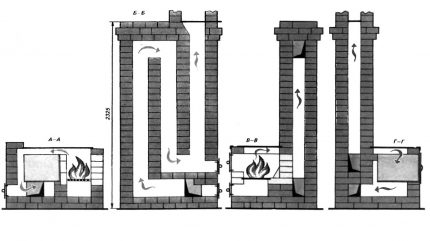

Option # 2: the advanced Teplushka stove

In order to get rid of the main drawback of brick kilns - uneven heating, standard designs are being modernized. An example is a stove called “Teplushka”, in which part of the flue gases from the cooking chamber is diverted directly to the chimney, and most of it runs along the smoke circuits in order to generate heat for the rooms.

This building belongs to the bell dome class. Structurally, it is one large-sized hood, which is divided into two chambers: a cooking stove, located at the top, and a heating, arranged at the bottom. To fix the hearth inside a virtually hollow structure, several columns are installed.

The chambers are connected to each other by means of four holes arranged on the sides of the hearth. Through them, flue gases from the furnace are sent to the cooking compartment, then redirected down to the heating zone, and from there they are vented to the atmosphere.The height of the chimney should be at least 5 m, and consider it from the bottom of the firebox.

Thanks to the non-standard design, the productivity of the stove is increased by about 2.5 times. It warms up faster and more willingly transfers heat to the premises, which means that less firewood is required to obtain and maintain the desired temperature. But the construction will take as much brick, bonding and insulating material as it takes to build a Russian stove.

During two furnaces, the stove produces 3200 kcal / hour. The unit is suitable for serving an area of 35 m².

The chimney is offset to the side of the firebox. At the bottom of the smoke channel there are two openings through which cooled smoke is discharged outside the house. A valve is provided that allows the removal of gases from the cooking chamber in the summer, without involving the heating part in operation.

Cooking in such an oven is carried out with the shutter closed, the process is monitored through the eye arranged in it.

We will not dwell on the analysis of the rules, the schemes show the masonry in detail. Just note that in the 21st row, the ceiling is covered with sand and cracked bricks to increase the heat transfer of the structure.

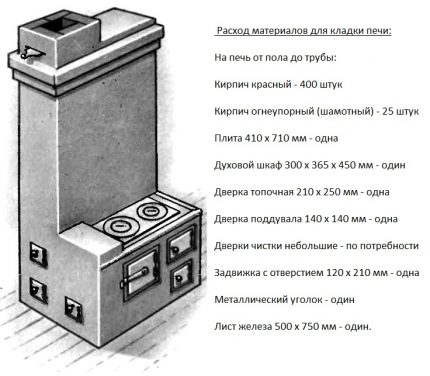

Option # 3: a simple stove with a shield

We want to please the adherents of simple heating and cooking units with an extremely simple design. This stove is designed to heat a small area of 15-20 m².

The principle of operation of this stove is also extremely simple. Gases from the furnace enter the cooking chamber. From there, they flow to the side, then move to the chimneys built in the rear wall.

In order to better warm the bottom of the stove, a horizontal channel is arranged, within which the smoke lingers for a long time.

Warming up the bottom of the brick structure, the smoke under the pressure of the next portion passes into the three vertical channels located above, from which it flies further into the atmosphere.

Conclusions and useful video on the topic

Video instruction on the construction of a heating and cooking unit:

Video guide on the competent overlapping of horizontal channels in the furnace and the basic techniques for their implementation:

Video lesson on the implementation of facing a firebox with refractory bricks:

The construction of a brick furnace in a country house requires concentrated attention, a thoughtful approach and a balanced assessment. Such a thing does not endure fuss. It doesn’t matter if you yourself undertake the construction or control the hired stove-makers, you need to thoroughly understand the issue of the device and the masonry, which we tried to help you with.

If you know firsthand how brick stoves are being built, please share your knowledge with our readers - leave your comments in the block below. There you can ask a question about the topic of the article, and we will try to respond to them promptly.

A furnace with a water circuit for heating a house: features of furnace heating + selection of the best option

A furnace with a water circuit for heating a house: features of furnace heating + selection of the best option  Russian bath stove: TOP-10 and guidelines for choosing the best model of a sauna stove

Russian bath stove: TOP-10 and guidelines for choosing the best model of a sauna stove  Wood stoves for heating a private house: rating of popular models + benchmarks for the buyer

Wood stoves for heating a private house: rating of popular models + benchmarks for the buyer  Types of brick ovens for the home: types of units according to purpose and design features

Types of brick ovens for the home: types of units according to purpose and design features  Gas bath stove: TOP-10 rating of sauna stoves for Russian and Finnish baths

Gas bath stove: TOP-10 rating of sauna stoves for Russian and Finnish baths  Brick stoves for giving on wood: the best orders and a step-by-step guide to the construction

Brick stoves for giving on wood: the best orders and a step-by-step guide to the construction  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Brick for a stove is now very expensive. A good refractory costs 30 rubles apiece at least, and with a brand higher and more cost. But there is an option to save. Buy bricks already used in the old stove. They are not inferior in quality to new ones. Only, of course, you need to pick them up without cracks. Silicate brick, if the customer wants, I use only for the foundation. For laying an array, it is not at all suitable. It is possible to revet the finished stove not with tiles, but with clinker tiles.

All vertical channel furnaces have one problem. It’s hard to rekindle. Especially if the pipe comes out low. I once solved this problem with a built-in valve in the first channel. In the open state, it connected the channel to the pipe, with such direct draft the furnace was easily ignited even at high humidity. I kindled and closed the damper - the heat went through the channels and the whole furnace warms up.