How to make steam heating yourself: device, rules and requirements

Each house should be warm, otherwise living in it will be very uncomfortable, even if it is very spacious and beautiful. Owners solve the heating problem in different ways, based on their own capabilities and climatic conditions.

Some equip houses with steam heating: it is quite simple to assemble such a system with your own hands. How to do it? Let's try to figure it out.

The content of the article:

The principle of operation of steam heating

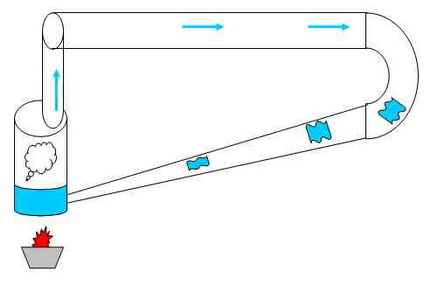

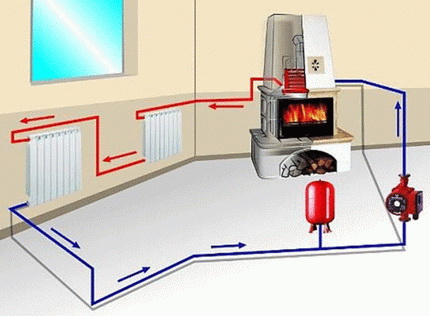

Many confuse the system of steam and water heating. Indeed, in appearance they are very similar. In both cases, there is always a boiler, pipes and radiators. But for the steam system, steam acts as a coolant, for water - water.

This is the fundamental difference between the two systems. The boiler does not heat, but evaporates water, the resulting steam moves through pipes to radiators.

Inside them, cooling and condensation of steam occurs. In the process of condensation, a kilogram of steam releases more than 2000 kJ of heat, while water cooling at 50 ° C will produce only 120 kJ.

It is clear that the heat transfer of steam is many times greater, which explains the high efficiency of this type of heating. Condensate formed inside the radiators flows into the lower part of the parts and flows by gravity towards the boiler.

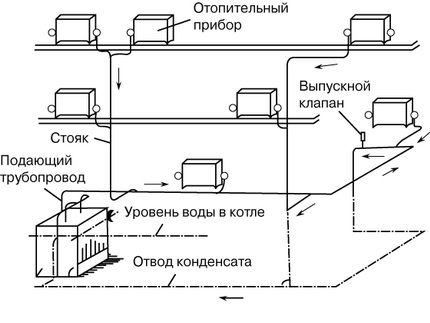

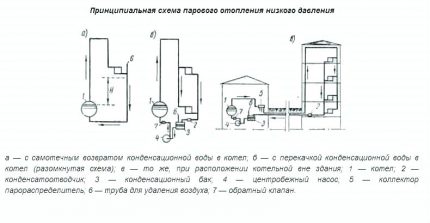

By the method of returning the coolant that has turned into condensate, all types of steam heating systems are divided into two varieties:

- Closed. In this case, there are no gaps in the circuit, and condensate flows through pipes laid at a certain angle directly into the boiler for subsequent heating.

- Open. The system is distinguished by the presence of a storage tank, where condensate from radiators enters. From this tank, he is pumped back into the boiler using a pump.

According to the methods of pipe assembly and wiring, steam heating circuits are divided into types that are absolutely similar to water systems.

According to the absolute pressure parameters of the heating system, steam is divided into high-pressure varieties with an excess index> 0.07 MPa; low pressure with excess pressure in the range of 0.005-0.07 MPa; vacuum with absolute pressure <0.1 MPa.

If there are sections or devices in the low pressure circuits that communicate with the atmosphere, they are classified as open, if not closed.

Why choose steam heating?

Admittedly, steam heating systems cannot be considered very popular. Such heating is rather rare. We consider in detail its advantages and disadvantages.

The first, no doubt, include:

- The efficiency of the heating system. It is so high that a small number of radiators are enough to heat the rooms, and in some cases you can do without them: there will be enough pipes.

- Low inertia of the system, due to which the heating circuit warms up very quickly. Just a few minutes after starting the boiler, the rooms begin to feel warm.

- Heat losses in the system are practically absent, which makes it very economical in comparison with others.

- The possibility of rare use, because due to the small amount of water in the pipes, the system does not defrost. As an option, it can be installed in country houses where people come from time to time.

The main advantage of steam heating is considered to be its efficiency. Initial costs for its arrangement are rather modest; during operation it requires relatively small investments.

However, even with so many advantages, the disadvantages of the system are very significant. They are primarily associated with the fact that water vapor is used as a heat carrier, the temperature of which is very high.

Due to this, all elements of the system are heated to 100 ° C and even higher. It is clear that any accidental contact with them will cause a burn. Therefore, all radiators, pipes and other structural details must be closed. Especially if there are children in the house.

The high temperature of radiators and pipes provokes active air circulation in the room, which is quite uncomfortable and sometimes dangerous, for example, with an allergic reaction to dust.

When using steam heating, the air in the rooms becomes too dry. Hot pipes and radiators dry it. This requires additional use. humidifiers.

Not all finishing materials that decorate rooms heated in this way can withstand the proximity to incandescent radiators and pipes. Therefore, their choice is very limited.

The most acceptable option in this case is cement plaster painted with heat-resistant paint. Everything else is in question. Steam heating has one more disadvantage that affects the comfort of those living in the house: the noise produced by the steam passing through the pipes.

The more significant disadvantages include poor adjustability of the system. The heat transfer of the structure can hardly be controlled, which leads to overheating of the premises.

There are solutions. The first is the installation of automation, which will turn on the boiler when the rooms cool down. In this case, living in the house will be quite uncomfortable from the constant temperature fluctuation.

A more “gentle”, but time-consuming method is arranging several parallel branches that will need to be put into operation as necessary.

The main disadvantage of steam heating, because of which it is not used much, is its increased emergency hazard. You need to understand that if a gust occurs from a pipe or radiator, hot steam will beat under pressure, which is extremely dangerous.

That is why such systems are now prohibited in multi-apartment buildings and are less commonly used in manufacturing. In private houses, they can be equipped under the personal responsibility of the owner.

The main elements of the steam system

The steam system includes several essential elements. Let's consider each of them in more detail.

Steam boiler - the heart of the system

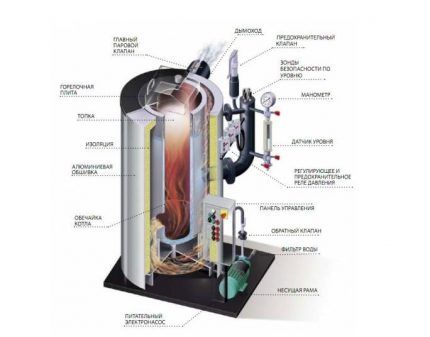

The main function of the heater is to convert water to steam, which subsequently enters the pipeline. The main structural elements of the device are collectors, a drum and pipelines.

In addition, there is a container with water, which is called the water space. Above it, during the operation of the device, vapor space is formed. They are separated by the so-called evaporation mirror.

Inside the steam space can be installed additional equipment designed for the separation of steam. The operation of the boiler is based on the principle of heat exchange of flue gases, water and steam.

There are two varieties of steam heating devices: fire-tube and water-tube. In the first case, heated gases move inside the pipeline laid inside the tank with water.

They give off heat to the liquid, which reaches a boiling state. Water pipe species work a little differently. Here, through the pipes laid inside the chamber with flue gases, water moves. She warms up and boils.

Water and steam inside the boiler can move forcibly or naturally. In the first case, the pump is included in the design, in the second - the difference in the densities of water and steam is used.

In all varieties of steam boilers, approximately the same principle of converting water into steam is used:

- The prepared liquid is supplied to the tank located in the upper part of the boiler.

- From here, water flows down the pipes into the collector.

- Fluid from the reservoir rises to the upper drum, passing through the heating zone.

- Inside the pipe with water, as a result of heating, steam forms, which rises.

- Steam, if necessary, is passed through a separator, where it is separated from the water. After which he enters the steam line.

A steam boiler can use a wide variety of fuels. Depending on this, certain changes are made to its design. They touch the combustion chamber. For solid fuel, a grate is installed, on which coal, firewood, etc. are placed.

For liquid and gaseous fuels, special burners are used. There are also practical combined options.

Depending on the heated area, the boiler power is selected.

This can be done based on averaged values:

- 25 kW for buildings up to 200 sq. m;

- 30 kW for homes ranging from 200 to 300 square meters. m;

- 35-60 kW for buildings from 300 to 600 square meters. m

If you need more accurate data, use the standard calculation method, where for every 10 square meters. meters accounted for 1 kW of equipment power. Do not forget that the formula is used for houses with a ceiling height of 2.7 m or less.

For higher buildings, you need to take more power. When choosing a boiler, special attention should be paid to its certification. Any steam heating system is potentially dangerous, therefore testing equipment is mandatory.

Pipes and radiators

The temperature of the coolant in steam systems ranges from 100 to 130 ° C, which is much higher than in liquid systems, where it is from 70 to 90 ° C. Therefore, the use of similar equipment for equipping systems is strongly discouraged.

First of all, this concerns metal-plastic and polypropylene pipes. The maximum operating temperatures for these materials vary between 90-100 ° C, therefore their use is strictly prohibited.

For pipelines of steam systems, three types of pipes are usually used. The most inexpensive option is steel. They easily withstand temperatures of 130 ° C, which is more than enough, and differ in sufficient strength.

However, the condensate formed inside the parts pretty quickly destroys the pipes, since steel is susceptible to corrosion, and the aggressive atmosphere formed by steam only reinforces this disadvantage.

Another drawback of steel elements is the need for joining by welding, which takes a lot of time and effort. Galvanized steel pipes are much more resistant to corrosion. They also withstand high temperatures.

The threaded method is usually used to connect them, which greatly simplifies the process. The main disadvantage of galvanized pipes is their high cost.

Ideal option considered copper pipes. The material withstands high temperatures, is sufficiently ductile and yet durable, not susceptible to corrosion. Soldering is used to connect copper parts.

Copper pipelines are very durable and strong, but their cost is very high. Thus, the most acceptable option in terms of quality and price is steel pipes with an anti-corrosion coating or galvanized.

Radiators for steam systems are selected according to the principle of strength. It is important that they withstand high temperatures and are resistant to corrosion. Based on this, massive can be considered the best option. cast iron batteriesthe worst - steel panel.

Given the high efficiency of the system, in some cases the use of finned steel pipes is quite acceptable.

Instrumentation Unit

The steam heating system is characterized by increased emergency danger, therefore, the presence of monitoring devices is mandatory. The pressure in the system is monitored, if necessary, it normalizes. For these purposes, a gearbox is usually used.

The device is equipped with a valve through which excess steam is removed from the system. For powerful installations, you may need not one, but several such valves.

Varieties of heating system

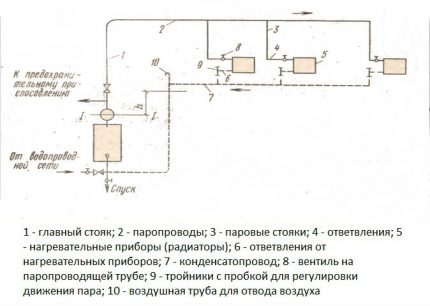

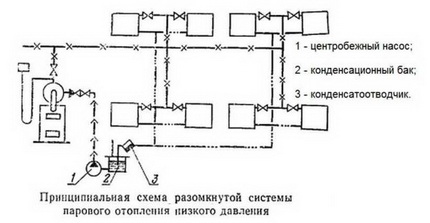

In practice, you can find a fairly large number of variations of steam heating. By the number of pipes, one and two-pipe varieties of steam systems are distinguished. In the first case, the steam moves continuously through the pipe.

In the first part of his journey, he gives up heat to the batteries and gradually turns into a liquid state. Then it moves like condensate. So that there are no obstacles to the coolant, the pipe diameter should be large enough.

A significant disadvantage of the single pipe system is the difference in the heating of the radiators. Those located closer to the boiler are heated more. Those next are smaller. But this difference will be noticeable only in large buildings. AT double pipe systems steam moves through one pipe, condensate flows through another. Thus, it is possible to make the temperature in all radiators equal.

But at the same time, the consumption of pipes increases significantly. Like water, steam heating can be single or dual circuit. In the first case, the system is used only for heating rooms, in the second - also for heating water for domestic purposes. The distribution of heating is also different.

Three options are practiced:

- Top wired. The main steam line is laid above the heating devices, pipes from it to the radiators drop from it. Even lower, a condensate line is laid at the floor itself. The system is the most stable and easiest to implement.

- With bottom wiring. The line is located below the steam heating appliances. As a result, steam moves in the same pipe, which should be slightly larger than usual diameter, in one direction, and condensate in the opposite direction. This provokes water hammer and depressurization of the structure.

- With mixed wiring. The steam pipe is mounted slightly above the level of the radiators. Everything else is the same as in a top-wired system, thanks to which it is possible to preserve all its advantages. The main disadvantage is the high risk of injury due to easy access to hot pipes.

When arranging the circuit with natural coercion, it must be remembered that the steam pipe is mounted with a slight slope in the direction of steam movement, and the condensate pipe is condensate.

The slope should be 0.01 - 0.005, i.e. for each linear meter of a horizontal branch there should be 1.0 - 0.5 cm of a bias. The inclined position of the steam and condensate pipelines will eliminate the noise of the steam passing through the pipes and provide free condensate drainage.

According to the level of internal pressure of the system, two main varieties are distinguished:

- Vacuum The complete tightness of the system is assumed, inside which a special pump is created, creating a vacuum. As a result, the vapor condenses at lower temperatures, which makes such a system relatively safe.

- Atmospheric. The pressure inside the circuit is several times higher than atmospheric. In the event of an accident, this is extremely dangerous. In addition, radiators operating in such a system are heated to very high temperatures.

There are many options for arranging steam heating, so everyone can choose the best option for their home, taking into account all the features of the building.

How to equip a boiler room?

A steam boiler operating on any fuel should be installed only in a room specially equipped for this.

The standards developed for standard steam appliances with a pressure of up to 0.07 MPa, generating steam with a temperature of 120-130 ° C, provide for a number of requirements for such boiler rooms:

- the distance from the walls to the heater cannot be less than 100 cm;

- the height of the room should be at least 220 cm;

- minimum fire resistance of doors - 30 minutes, walls - 75 minutes;

- the presence of quality ventilation;

- the presence of doors and windows facing the street.

It is best to equip a boiler room in separate roombut blocking of a suitable room is also allowed. Inside it must be finished with non-combustible materials. Ceramic tiles are best suited for these purposes.

Preparing for the installation of a steam system

To properly make steam heating, you need to start with the preparation of the project. Its development is a difficult task, which is best solved by specialists. In the finished project, many points should be taken into account.

First of all, the calculation of thermal loads on each of the premises and on the building as a whole is performed. A steam source is selected, and the mechanism and degree of automation of the system is determined.

In addition, the steam consumption is necessarily determined, on the basis of this, the equipment and the scheme for its use are selected. After the project is ready, you can begin to draw up an installation plan.

For its implementation, a building plan will be required, on which the equipment locations are applied. They usually start with a boiler. Its location is determined. If the system has natural circulation, the boiler must be below the battery level.

In this case, it is usually lowered into the basement or the basement, so condensate can drain to the device on its own. Then, the layout of the entire heating system is applied to the house plan. Moreover, all the necessary equipment is noted.

Experts advise to perform this operation directly "in place", being in the room where the equipment will be located. This is the only way to notice and take into account all the protrusions and obstacles that will have to be circled.

All transitions and angles are necessarily marked on the diagram. After it is finished, you can proceed to calculate the amount of material necessary for its implementation. Once again, it is worth paying attention to the importance of the right choice of equipment.

The steam system is potentially accidentally dangerous, so you should not save on materials and devices. Everything must be of high quality and certified, otherwise serious problems cannot be avoided.

Steam heating installation technology

Start work with the installation of a heating boiler. It is mounted in a prepared room on a concrete base. In some cases, a separate small foundation is prepared for the equipment.

The device is installed on the base strictly horizontally, the correctness is checked by the building level. Noticed errors are immediately eliminated.

The boiler placed on the base is connected to the exhaust system. The connection must be strong and completely tight.

The next stage is the suspension of radiators. To do this, in the places indicated on the installation diagram, special hooks are driven into the wall, on which the batteries are mounted. If it is intended to use finned tubes, then they are fixed.

The strength of the heat emitters is checked. Next, you can begin to equip the expansion tank. It is fixed at the highest point at a small distance from the boiler, it is best to keep this distance as small as possible.

Now you can install a group of control devices. They are mounted at the exit of the boiler. At a minimum, a pressure gauge and a relief valve should be located here.

All installed equipment is interconnected by pipes. The connection method depends on the material from which they are made. In any case, the correctness and reliability of the connections made should be carefully checked.

For open systems, a condensate collection tank is installed at the end of the line and a pump is mounted. The pipe that goes from it to the heating appliance should have a smaller diameter than the other pipes.

The steam boiler is connected to the heating circuit. At the same time, all necessary shutoff valves and filters must be installed, which will delay large particles of dirt that may be contained in the water.

If the equipment runs on gas, the fuel line is connected. Flexible hoses are not allowed in this case - only rigid eyeliner.

Next, you can conduct a test run. To do this, water is poured into the circuit, after which the equipment is put into operation. First, at the minimum operating temperature, then it is gradually increased, while monitoring the correct operation and integrity of the system.

If the slightest flaws are identified, the equipment is stopped and all malfunctions in its operation are eliminated.

Conclusions and useful video on the topic

How to convert a stove into a steam boiler:

The principle of operation of a steam boiler:

Home-made steam heating:

Steam heating is a very simple and economical way to heat a house. Many are attracted by its minimal heat loss, high efficiency and low maintenance.

However, it must be remembered that steam heating is potentially dangerous, and an emergency in this case can lead to serious injuries. Therefore, it is necessary to take its calculation and arrangement seriously.

After reading the material, there were questions and would you like to get an answer? Please leave your comments in the block below, share your experience in arranging steam heating, and participate in the discussion of the topic.

Steam heating in a private house and in a country house based on a stove or boiler

Steam heating in a private house and in a country house based on a stove or boiler  Do-it-yourself water heating: all about water heating systems

Do-it-yourself water heating: all about water heating systems  DIY air heating: all about air heating systems

DIY air heating: all about air heating systems  How to arrange air heating of a country house: rules and schemes of construction

How to arrange air heating of a country house: rules and schemes of construction  Water heating in a private house: rules, norms and organization options

Water heating in a private house: rules, norms and organization options  How the boiler is strapped with polypropylene: the rules for the construction of the pp circuit

How the boiler is strapped with polypropylene: the rules for the construction of the pp circuit  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Although such a heating system is rather rare, I decided recently to install it in my country house and did not regret it. Firstly, it is very convenient, as the rooms warm up much faster than with water heating. Secondly, it is not expensive, the installation costs are minimal, and the savings in the future are noticeable. For a summer residence, this is the best option, since it is much easier and faster to drain the condensate from the conservation system than to prepare the water circuit for wintering.

Not for nothing that steam heating was abandoned all over the world. This solution is not optimal. It’s also expensive and dangerous.