Water copper pipes: assortment marking, scope, advantages

Exceptional reliability, anti-corrosion properties and resistance to water shocks bring water copper pipes to the leadership position of pipe fittings. The limited operation of copper rolling is a consequence of the high cost of products.

Nevertheless, capital investments in the water supply system are justified and allow the consumer not to think about reconstructing the engineering network for decades. In addition to durability, in this article we will analyze other advantages of the copper pipeline, and note the disadvantages.

We also consider the composition, basic characteristics, features of the marking of copper pipes and the features of their application in various fields.

The content of the article:

Composition and characteristics of copper pipes

Copper water supply is a rather exclusive option for arranging a communication system. Despite the mass of absolute advantages, copper is being used less and less. The main reason is the appearance of available alternative materials (plastic and metal-plastic fittings).

The metal alloy M1 is characterized by the highest copper content. The purity of the alloy provides high ductility, electrical and thermal conductivity, as well as corrosion resistance. The material is malleable to different processing technologies.

Mass fraction of components of the M1 alloy:

- copper and silver - 99.9;

- oxygen - 50;

- iron, lead - 5 each;

- sulfur, zinc - 4 each;

- tin, antimony, arsenic and nickel - 2 each;

- bismuth - 1.

In M2, the mass fraction of copper / silver is reduced to 99.7, the nickel and oxygen content are increased to 200 and 70, respectively.The proportion of tin and iron is increased to 50. The primary copper alloy has similar characteristics with the M1 metal alloy.

Technical copper (M3) is the result of secondary smelting or fire refining. The material has a significant mass fraction of nickel (200), tin, lead and arsenic (80 each). The copper content is 99.5. M3 alloy copper pipes have good strength and affordable cost.

Characteristics of copper pipes:

- operating temperature range - from -200 ° С to +300 ° С;

- permissible pressure is 100-200 atmospheres (for a number of grades the limit value reaches 450 atmospheres);

- relative elongation at break - 10-40%;

- diameter of water fittings - 3-350 mm, wall thickness - 0.8-10 mm;

- estimated service life - more than 70 years.

The critical operating temperature of a copper water supply depends on the method of connecting the elements and the type of solder used. In more detail about technology of installation of the copper pipeline talked here.

The actual period of service significantly exceeds the period declared by the manufacturer. The oldest copper communications in Europe are used without replacement for the second century.

Strengths and weaknesses of copper water supply

Copper pipes are similar to their closest competitors (steel communications) in terms of strength and temperature characteristics. However, copper is more preferred due to its unique properties.

The main advantages of copper pipes

Copper pipes have their positive and negative points. First, consider the benefits of a copper pipeline.

Corrosion resistance and ductility

Perhaps the main argument in favor of copper plumbing is immunity to rust. This property explains the uptime of utility networks and minimizes the negative impact on plumbing fixtures.

Plasticity - this quality explains a number of significant operational advantages of a copper pipeline:

- flexibility of material in processing - pipes can be bent to create complex trunk networks using a hand tool;

- retention of a given shape - soft polymer products cannot boast of this property;

- applicability connecting fittings;

- the likelihood of deformation without mechanical destruction;

- temperature jumps do not cause changes in linear parameters;

- maintenance of cycles of freezing / thawing with preservation of integrity.

Another point - increased resistance to water hammer. The indicator of destructive pressure allows you to not be afraid for the integrity of the system during the "jumps" of the water pressure.

Surface smoothness and bactericidal

An archival argument in favor of a water pipe made of copper.High uniformity of the material provides a perfectly even coating, which reduces the molecular bonds of the metal, which means that the formation of salts and oxides is reduced.

Copper alloy has an antibacterial property - circulating through pipes, the water is partially disinfected. An additional plus - colonies of microorganisms do not breed on the walls.

Resistance to chemicals and UV rays

Copper is not destroyed by interaction with saline solutions, formalion and dilute non-oxidizing acids. In contact with chlorine does not form oxides hazardous to humans.

Copper does not lose its characteristics under the influence of UV radiation, which can not be said about communications from thermoplastic polymers.

Along with good strength indicators, copper alloy pipes are slightly lighter in weight of steel counterparts. This facilitates their transportation and installation. The indisputable advantage of the copper pipeline is the possibility of multiple applications.

Cons of the copper pipe

The copper pipeline also has its negative aspects. Let's consider them in more detail.

The disadvantages of a copper water supply include:

- High price. When compared with the cost of analogues, copper products lose. Arranging a network of “yellow” metal will cost several times more than installing a plastic or steel line.

- The complexity of installation. All docking technology copper fittings (assembly on fittings or soldering) are quite complex processes that require work skills.

- Acid intolerance. It is impossible to use copper pipes to transport an acidic medium with a pH level of more than 9. Water with such an indicator is unsuitable for drinking.

- Thermal conductivity. The parameter is 1.7 times higher than that of aluminum products and almost six times higher than the thermal conductivity of steel. When transporting a hot medium, the pipe heats up - heat losses increase, there is a risk of burns. In cold water systems, condensation forms on the pipeline.

The problem can be solved by using a coating of polyvinyl chloride or polyethylene. The outer sleeve prevents condensation, “cools” the surface, maintains the temperature of the transported medium and reduces noise.

Copper pipes with external thermal insulation are used only in those cases when it is necessary to reduce the impact of the external environment on the water supplied by the system. They are also needed in order to prevent icy congestion, which can disrupt the functionality of the water supply.

Copper pipes themselves are not threatened by freezing and subsequent thawing.The ductility of copper allows you to maintain tightness even if the pipeline had to be slightly deformed under the influence of an ice plug.

Additional disadvantages of using copper are electrical conductivity, as well as incompatibility with aluminum and steel water pipes. To prevent the risk of electric shock during installation, care must be taken to properly ground the equipment.

A significant drawback of copper pipes is the occurrence of electrochemical corrosion, resulting from the contact of copper with other materials:

A variety of copper pipe rolling

The choice of material for the arrangement of a copper water supply system should be based on an assessment of a number of parameters: the manufacturing method, the level of lamination and strength, as well as the overall dimensions. The ability to decipher the marking of the assortment will help you navigate the variety of pipe fittings.

Classification # 1 - Production Method

Obtaining a copper pipe according to GOST is carried out according to one of the technologies: cold rolling, pressing followed by welding. Production tactics affect the performance of the finished product.

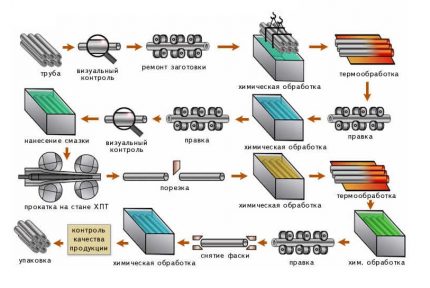

How to produce pipes by rolling?

The technology involves the deformation of a metal billet in the process of passing it between the rotating shafts of a tube rolling machine.

Break-in occurs step by step - with each feed, the sleeve rotates 90 °, ensuring uniform processing and the absence of longitudinal marks on the pipe.

Advantages of rolling fittings:

- seamless construction provides high strength;

- accuracy of parameters along the entire length of the product.

The method of cold deformation creates water and heating copper pipes that experience significant pressure from the inside during the service.

At the stage of final processing, pipe fittings can be subjected to thermal effects. This is done in order to return copper to its elasticity.

Pipes are:

- unannealed;

- annealed.

The unannealed following characteristics - “bending stiffness”, resistance to external damage and water hammer (limit - 450 MPa). Suitable for assembling water pipes of a simple configuration.

Annealed have the following parameters: high ductility (when stretched along the length of 1.5 times maintain integrity), increased cost.

Press manufacturing

Pipes are made of sheet copper - the blank of the metal sheet is fed to the molding press rollers of the machine. After shaping, the joint is welded.

The final stage is the passage of the pipe through the calibration rollers to align the profile and eliminate longitudinal deformation.

Classification # 2 - by degree of hardness

The mechanical properties and scope are determined by the type of pipe. It is customary to classify copper fittings into three categories characterizing the ductility and strength of the product.

Hard products

This niche is represented by unburnt specimens. Possible labeling of solid pipes: T, H, z6, F30. The material is optimal for creating central channels of water supply networks where high pressure water is supplied.

Semi-solid pipe type

Semi-solid pipe coding options: P, NN or z. They are characterized by balanced characteristics of elasticity and strength. The relative elongation of the pipe with an outer diameter of 3 mm and a wall thickness of 0.8 mm is 10%. The same indicator for soft rental of a similar size is 38%.

Parts made of semi-solid "meter" withstand the distribution of the expansion of the outer diameter by 15%. Changing the geometry of the pipeline is carried out using a pipe bender.

Soft Pipe Features

Marking of soft pipes - M, W, F22 or r. Products have flexibility and do not tear when distributing an outer diameter of up to 25%. Pipe products are supplied in bays.

The main field of application is the installation of engineering networks with a beam distribution of supply leads to devices. To get the desired shape of the small-diameter trunk will turn out personally without special equipment.

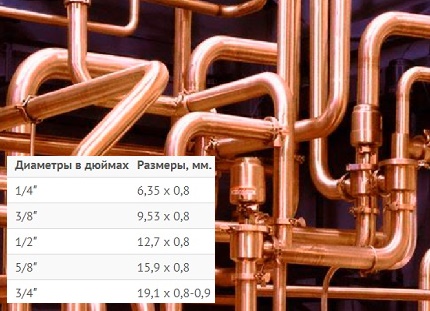

Classification # 3 - by overall dimensions

The main parameters of the pipe dimension are the inner, outer diameter and wall thickness. The flexibility of copper to processing allows the production of pipe lines of various shapes and sizes. GOST 617-2006 about 130 items with original cross-section indicators were ranked as a copper fittings range, of which about 70 were rolled products.

Unlike a previous document (GOST 617-19) in the new resolution, the dimension is displayed in millimeters, not inches. The main dimensions are indicated in fractional terms. The numerator identifies the outer diameter, the denominator identifies the wall thickness. Previously, only the external size (3/8 inch) was indicated.

An example of decoding the dimension of the pipe 15/1:

- diameter on the outer surface - 15 mm;

- internal section - 14 mm;

- wall thickness - 1 mm.

The length of rolled products of domestic production depends on the diameter. If the cross-sectional size is within 18 mm, there are coils of 10 m in length or measuring sections of 1-6 m (assortment pitch is 0.5 m). Larger specimens are produced in segments of 1.5-6 m.

Rectangular pipes are used much less frequently in water supply. The products are manufactured mainly by pressing technology, dimensions: diameter - 30-280 mm, wall thickness - 5-30 mm.

Regulatory requirements according to GOST

External parameters, mechanical characteristics, alloy composition, assortment and marking designations are regulated by two main provisions: GOST 617-2006 (Copper pipes for general use) and GOST 11383-75. European-made products meet standard EN-1057 from 2006.

Code of Requirements:

- The inner and outer surface of the pipe must not have any impurities that impede the inspection of products. The presence of delaminations, rusts, cracks and shells on the pipe "sleeve" is unacceptable.

- Dents up to 0.25 mm deep are acceptable. The quantity limit is no more than two per linear meter and no more than 10% of defective products per supply lot.

- No burrs at pipe ends. The normalized cut braid for specimens with a diameter of up to 20 mm is 2 mm, for products with a cross section of 20-170 mm - 3-5 mm, respectively, for pipe fittings with a diameter of 170 mm and more, a cut of 7 mm is permissible.

- For bays and soft pipes, ovality is not limited.

Each bay or batch of pipe cuts must be accompanied by a packing list and information label.

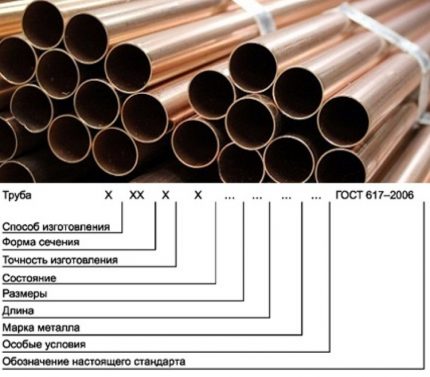

Explanation of the designations of pipe products

Basic features are grouped in pipe labeling.

Conditional indicators are prescribed according to a clearly defined scheme:

- Manufacturing technology: D - cold formed, G - pressing.

- Cross Cut Geometry: KR - round shape.

- Production accuracy indicator: N - within normal limits, P - increased accuracy with respect to diameter / wall thickness, And - high accuracy in diameter, K - maximum accuracy in the wall.

- Type of material in ductility. In addition to the indicated abbreviations M / P / T (soft / semi-solid / hard pipe), the following product markings are used: L - soft with high elasticity, F - semi-solid high strength, H - solid high strength.

- Dimensions - value of the outer diameter / wall thickness.

- Length: ND and MD - non-dimensional and measured pipelines, respectively, KD - multiple-gauge rolled products, BT - delivery in bays.

- Metal gradedetermining the composition of the alloy.

- Special conditions: B - high accuracy in length, O - accuracy in curvature, P - regulated tensile rate, H - confirmed Vickers hardness, BU and BS - ordered and spiral winding of the coil, respectively.

Instead of missing data, the designation "X" is put.

Scope and restrictions of use

Copper pipes are used in various communication systems for domestic and industrial use.

Water supply and heating network

Traditionally used in the arrangement of water supply of various target orientations. Characteristics of copper and an extensive line of pipe products allow you to equip highways of different capacities and meters.

In the heating network, a double effect is achieved. On the one hand, it is a long service life due to corrosion resistance, on the other hand, it protects the system from uncontrolled changes in the temperature of the coolant. But these effects are achieved only with the correct assembly of the pipeline.

In more detail about the varieties of copper pipes for heating and the features of their installation, we wrote in next article.

The use of a copper pipe with an insulating sheath is justified in "warm floor" systems.

Gas pipeline and fuel system

The convenience of copper rolling is the tightness of the line. When transporting gas, there is no oxidation and galvanic corrosion. Reliability of pressed joints and adhesions increases the safety of the gas pipeline in areas with seismic activity.

Thanks to neutrality, copper fittings are used in networks for pumping fuel oil - there is no risk of ignition, the formation of a static charge.

Nuances and limitations of use:

- The boundary velocity of fluid transportation in the water supply system is 2 m / s. Compliance with the recommendation will extend the service of the "plastic" highway.

- Copper is a soft metal and constant contact with a medium filled with solid particles can lead to a “leaching” of the walls. To prevent the formation of erosion, it is desirable to provide a preliminary purification of water from foreign suspensions. It is enough to install a filter of rough (mechanical) cleaning.

- Under favorable conditions, an oxide film appears on the inner walls of the copper pipe - the coating does not impair the quality of the water and protects the metal from wear. Requirements for the formation of patina: the pH of the aqueous stream is 6–9, the hardness is 1.42–3.42 mg / l. With other parameters, cyclic destruction and restoration of the film due to the expenditure of metal occurs.

- Lead solder should not be used for the installation of drinking water - metal and its compounds are toxic. The substance is able to accumulate in the body, exerting a gradual fatal effect on various organs.

Docking of copper communications with a pipeline made of brass and plastic is permissible. When combining copper pipes with steel and aluminum elements, the joining sequence must be adhered to.

In addition to soldering, the compression and crimping technologies are used in the connection of copper pipes:

Large diameter copper pipes are mainly connected by flanges and bolts screwed into them, soldering into the socket is allowed, compression methods are used extremely rarely.

Conclusions and useful video on the topic

Video reviews complement the information provided. Competitive advantages and negative characteristics of the copper pipeline, features of installation works:

Pipe connection technology using fittings and soldering:

Advantages of a copper water supply system are undeniable. A wide range of rolled products allows you to choose the best material for the solution of a particular problem. Subject to installation techniques and operational recommendations, an uninterrupted service of the water supply system is guaranteed for over 50 years.

Have you thought about buying copper pipes for installing a water supply system, but still doubt the feasibility of such a solution? Ask your questions under our article - our experts and owners of copper plumbing will help dispel your doubts.

If you are the owner of such a pipeline, write your opinion on its use, add real photos and recommendations for selection and installation.

Copper pipes for heating: types, specifics of marking + application features

Copper pipes for heating: types, specifics of marking + application features  Press fittings for plastic pipes: types, marking, purpose + installation example

Press fittings for plastic pipes: types, marking, purpose + installation example  DIY copper pipe installation: copper pipe installation technology

DIY copper pipe installation: copper pipe installation technology  How to choose fiberglass pipes: production specifics and an overview of leading manufacturers

How to choose fiberglass pipes: production specifics and an overview of leading manufacturers  Connecting copper pipes: instructions and comparison of various installation technologies

Connecting copper pipes: instructions and comparison of various installation technologies  Polypropylene pipes and fittings: types of PP products for the assembly of pipelines and methods of connection

Polypropylene pipes and fittings: types of PP products for the assembly of pipelines and methods of connection  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Copper pipes for home water supply are the most ideal option for their durability, reliability and antibacterial properties (neither mold nor bacteria reproduce). But, unfortunately, a very expensive option - not everyone can decide on this, they put mostly plastic. And it is better to put copper pipes on hot water with a heat-insulating coating so that the heat does not go into the air. Installation is time-consuming if soldered, but it was done once and for half a century is definitely enough. Thing!

The most reliable engineering networks only for welding and stainless steel. So, lovers of plastic and copper, do not fool around. One example is the use of stainless steel in the collapsed twin towers in the USA, built for centuries!

In general, copper has been standing for centuries and nothing. Plastic is not a topic here, but stainless steel is even more expensive than copper ... moreover, where can I get it? And the properties are almost the same.

Stainless steel pipes are not bad and quite competitive with copper pipes, both in price and quality. But nevertheless I will choose copper - it is much simpler and more convenient to install, resistant to corrosion, and generally more reliable.