We make a box for pipes in the bathroom: step-by-step installation instructions

Communications laid on the walls are unlikely to decorate the interior of the bathroom. For masking and decorating pipelines use a variety of structural forms, one of which is a box. Any home master can cope with its construction without problems if he is familiar with the technological subtleties. Right?

We will tell you how to make a beautiful and durable box for pipes in the bathroom with your own hands. For independent owners, we presented a number of the most popular options available to an inexperienced performer. The tips given in the article will ensure the impeccability of the result of the efforts made.

The content of the article:

- How to hide communications?

- Benefits of a camouflage box

- We choose building materials for installation

- Optimum design selection

- Preparing to install the box

- Necessary tools and materials

- Frame Installation Instructions

- Two options for covering the frame

- Installation of the invisible hatch

- Useful device tips

- Conclusions and useful video on the topic

How to hide communications?

The wiring in the bathroom includes pipes connected to various plumbing devices (bathtub, washbasin, and with a combined bathroom and toilet), as well as various devices and devices: valves, filters, water meters.

So that communication systems are not striking, they are hidden using various methods.

One of them is covert cabling. In this case, the pipes are hidden inside the walls, arranging special recesses-strobes in the latter.

True, this method is not universal, since it has a number of limitations:

- Wall chipping is possible only during overhaul, since in this case the complete elimination of finishing coatings and the replacement of communication equipment are required;

- when installing a hidden wiring, it is impossible to hide a filter, counter or other device;

- building standards prohibit punching gates in load-bearing structures, since they sharply reduce the strength of the walls;

- there are restrictions on the dimensional characteristics of pipes that are used for hidden wiring: their diameter should not exceed 50 mm. Therefore, this method is in no way suitable for masking a thick sewer pipe;

- this method is not suitable for risers, the appearance of which is unlikely to decorate the interior of the bathroom.

An alternative to hidden wiring is considered a combined system that provides for the installation of a duct on the surface of the walls. In this case, the pipes are placed in a specially allocated space, and the outer walls are finished in accordance with the style of the interior.

Benefits of a camouflage box

In the design of modern bathrooms quite often such designs are used that mask one or several pipes, since the boxes have a number of indisputable advantages.

Similar designs are characteristic of:

- A neat appearance, which is achieved using high-quality materials for the manufacture and decoration of the structure.

- Easy installation. The system can be performed not only during overhaul, but also during cosmetic repairs, since the box can be installed even on top of the finished decoration.

- Providing easy access to the pipeline, which allows not only to take meter readings, but also to monitor the condition of the pipes, and, if necessary, repair devices and communications.

- The possibility of combining the box with the installation for the toilet, shelves and other details, thereby achieving optimal use of the area of even a small room.

Carefully executed and finished box can be a real decoration of the bathroom, combining functionality and aesthetics.

We choose building materials for installation

To make the box, you must first build a frame, which is then covered with cladding material, and often also additionally finished, for example, covered with tiles. The base is made of galvanized metal rails (vertical and horizontal).

As a coating, various types of building materials can be used, which should have a number of qualities, namely:

- Moisture resistant. Boxes are located in bathrooms, which contain an increased percentage of water vapor.

- Light weight and small thickness. Both simplicity of installation and the size of the finished structure depend on these factors: too dense walls can “take away” a significant part of the space.

- Environmental friendliness. Such constructions should not emit toxic substances or have a pronounced allergenic effect.

- Aesthetic appearance or the possibility of additional decoration.

Most often, the following varieties of materials are used for cladding.

Option # 1: plastic panels (PVC)

Polymer panels have a beautiful appearance. They are available in a large assortment, which allows you to choose a finishing material that matches perfectly with the color palette of the bathroom.

In addition to aesthetics, PVC panels have high consumer qualities:

- perfect water resistance;

- resistance to deformation and mechanical damage;

- durability: flexible and durable plastic can last for many years;

- ease of maintenance - it is enough to wipe the contaminated parts with a damp cloth;

- ease of installation: to work with this material does not require special professional skills and special equipment;

- availability: PVC panels - a low-cost finishing material that has a low cost;

- the possibility of quick repair: damaged structural elements can be removed without destroying the entire box;

- compactness. The panels have a small thickness, so the structures built from them do not take up much space, which is extremely important for miniature rooms.

As an alternative to plastic panels, drywall is usually used, which is widely used in construction.

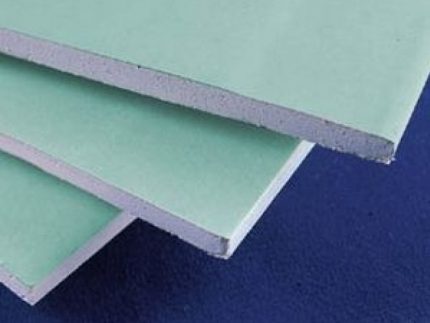

Option # 2: moisture resistant plasterboard

There are various varieties of this popular material. To design a bathroom, you should not use standard drywall (GKL), intended for rooms where moderate humidity reigns (up to 70%).

At the same time, a moisture-resistant type of drywall - GKVL, which is easily recognizable by the green surface of the plates, is well suited for finishing the plumbing unit. Such sheets are suitable for both standard facing works and for creating complex structures with convex, concave and curved surfaces (in this case, however, working with drywall requires special skills).

Another additional advantage of GKVL is the impregnation of plates with antifungal drugs that prevent the development of harmful mold.

At the same time, when choosing a material, some features of drywall should be taken into account:

- Installation of structures made of gypsum plasterboard or gypsum plasterboard requires more effort than installing systems made of plastic or MDF boards.

- It will not be possible to make a collapsible structure out of drywall, therefore, in the manufacture of the box, it is imperative to provide for a door or hatch that provides access to valves, counters and other elements of the communication system.

- GKL (GKVL) plates are not the finishing material: when making a box from them, it is important to consider the finish. Given the high humidity in bathrooms, tile paneling is usually used, but other types of decoration can also be used: paint, decorative plaster, wallpaper.

It is important to note that experts advise to additionally impregnate even moisture-resistant plates with a special composition in order to increase the strength and resistance of the element to moisture.

In addition, you can build a box from other materials.

Option # 3: Water Resistant Plywood

This modification differs from ordinary plywood in the special composition of the glue used. The sheets have a thickness of 6 to 40 millimeters and quite good consumer properties, however, despite the name, it is better to further process them with special compounds that improve water resistance.

The main disadvantage of waterproof plywood is its high cost, because of which it is used less often than other building materials.

Option # 4: MDF and HDF boards

Sometimes you can find tips on using for the device boxes from MDF panels (Medium Density Fibreboard - medium density fiberboards). It is hardly worth following such recommendations, since this material absorbs water vapor well and is not very suitable for wet rooms.

It is much more advisable to cover the structure with HDF sheets (High Density Fiberbord). This material is well resistant to moisture, due to which the designs made from it do not lose their properties for 10 or more years.

Option # 5: OSB boards

Another suitable option, allowing successfully hide pipes in the bathroom, can become oriented chip boards (OSB, OSB, Oriented Strand Board) - multilayer sheets glued with resins, into which synthetic wax and other additives are added.

There are several varieties of this material.For the manufacture of boxes it is best to stay on sheets OSB3 (with additional impregnation), as well as sheets OSB4. The latter can be used for especially durable structures or in places where a heavy load falls.

For the construction of the box with sheathing from OSB, plastic panels, plywood, it is better to build the box from lumber:

Optimum design selection

Protective and decorative structures for pipes can be performed in different ways, and the most common configurations are as follows.

Wardrobes. This option is usually provided for risers and other vertical systems. The design provides full access to communications. In addition, it is easy to combine with shelves and other devices that allow you to maximize the usable area.

Partition Boxes. These structures are installed over the entire width and height of the room, practically isolating a certain part. Although in this case the bathroom area is slightly reduced, the room looks very neat, since all communication systems are masked.

The option is especially suitable for spacious bathrooms. It can also be advised when using wall mounted toilet, since the partition simultaneously with the communication systems allows you to hide the installation. Devices for storing necessary things, for example, household chemical products, can also be placed behind the partition.

Compact boxconstructed around pipes. The most commonly used design, which practically does not absorb space, but gives the interior a neat appearance. Such systems can be either vertical or horizontal, adjacent to the floor or ceiling.

Below we will analyze in detail the stages of manufacturing such a design.

Preparing to install the box

Before starting the construction of the structure, preliminary work should be carried out.

If a new pipeline is being laid, it is desirable to provide for a minimum number of compounds.

Then choose the design of the box, which would be best suited for placing the bathroom, take all the necessary measurements, and then perform a sketch drawing of the structure. In this case, it is imperative to provide access to devices and devices (filters, valves).

According to the diagram drawn, the necessary number of building materials should be calculated, providing for a small margin.

It is also important to stock up on all the necessary equipment in advance, as well as purchase panels, guides and other necessary structural elements.They need to be carefully inspected in order to identify chips, defects and damage in time.

Necessary tools and materials

If it’s already decided which box is best hide heating pipes, water disposal and water supply, then you should deal with the preparation of tools, fasteners and materials.

For the construction of the box, the following devices will be needed:

- well sharpened construction knife;

- roulette;

- scissors for metal;

- level or square;

- screwdriver or screwdriver;

- pencil;

- fasteners (screws, euro screws, dowels);

- drill or punch.

From the materials you should purchase:

- galvanized metal profiles (types ud, cd);

- silicone sealant;

- GVKL, HDF, OSB boards or plastic panels (in the latter case, it is important to choose a shade that matches the interior color palette);

- PVC skirting boards designed to mask joints with walls.

Putty and corners may also be needed to prepare the drywall box for additional finishing.

Frame Installation Instructions

Regardless of what type of coating the box design provides for, first of all, a metal frame should be installed. To do this, it is important to adhere to the following regulations. Work should begin with the walls adjacent to the corner.

First of all, you need to make markings on vertical and horizontal surfaces.

After that, you should install the guides (ud profile), which specify the dimensions of the box. To attach them to the surface, you can use Euroscrews (dowels) by drilling holes in the corresponding places with a drill. For walls faced with tiles, “flea” self-tapping screws (length 2.5 mm, diameter 3.5 mm) are well suited, which can be screwed into inter-tile seams.

If the pipes go horizontally, it is enough to expand the guides in parallel to the floor and fix them. After this, the outer corner should be formed by twisting the corner post of two ud profiles. Their shelves must be directed at right angles in different directions, and then connected with small screws.

The supporting profile cd is cut with a knife into parts whose dimensions correspond to the width and length of the box. On the vertical surface, the first angular rib is fixed, which determines the rigidity. The obtained sections of the profile are inserted at one end into the installed guide and at the other into the stiffener so that parts of the angle are connected to the profile.

At a certain distance, which can vary from 30 to 70 cm, jumpers should be added - they give the system strength and reliability, and are also used for hanging panels.

After completing the work on one side, the second angular profile is attached to the other wall in the same way, after which the work on creating the frame of the box is considered finished.

Two options for covering the frame

The base should be connected to the elements of the finishing material. Consider the most common options, each of which has its own characteristics.

Work with PVC panels

This is one of the easiest ways to mask pipes.

Instructions for implementation:

- Install the starting profile, carefully securing it with small screws on the installed guide piece.Measure the strip of plastic panel of the required size, and then cut it with a knife.

- Fix one panel in the start profile, fix the other to the corner profile, and then install the latter to another plane of the box. For fasteners, you can use the "flea" (small screws).

- Using the same method, the second side of the box is assembled, while the starting profile is fixed and fixed on the last plastic panel, which is most easily done with silicone sealant.

- In places where it is necessary to provide access to important communication elements (cranes, joints, counters), it is important to cut through the inspection holes on which special hatches are fixed (using sealant or other methods).

- At the end of the work, plastic skirting boards should be installed at the joints of the panels with the floor, walls, and ceiling.

To quickly disassemble the plastic box, it is important to remember which side the loose panel is left on. If necessary, this element is pulled as far as possible to the side, and then taken and removed.

After inspection of the pipes or repair work, the integrity of the structure is restored by the same method: the angle of the panel is pulled back, after which it returns to its place.

Work with GVKL plates

Installation of drywall construction is also quite easy.

Procedure:

- First of all, it is necessary to correctly lay out the GVKL sheets in accordance with the calculated sizes. To do this, they need to be placed on a flat surface, marked with a tape measure and apply small cuts on the surface.

- The notches must be combined with a metal ruler or a long rail, and then cut the surface with a construction knife. On the drawn line, the plasterboard sheet should be broken, if necessary, aligning the edge with a knife.

- Blocks prepared in this way are attached to the frame using self-tapping screws. In this case, the sheets are pressed as tightly as possible to the profiles, and the screws are screwed first into the drywall, and then into the metal guides.

- It is important to ensure that the caps of the fasteners are necessarily screwed on the surface line or even lower, which is especially important if you plan to further finish the box with tiles. In order to prevent the appearance of cracks on the GKVL panels, it is important to screw the screws at a distance of 20-30 mm from the edges.

After completing the installation, it is important to prepare the design for subsequent finishing work. To do this, joints and places of contact with horizontal surfaces are treated with sealants to create a dense protective layer.

After that, the surface is covered with putty, covering the fasteners. You can strengthen the fasteners by installing perforated corners on the inner and outer corners of the parts. After finishing work and drying the structure well, you can proceed to gluing tiles or performing other finishing works.

Installation of the invisible hatch

To provide access to the pipes with a drywall construction, you can use a ready-made plastic door or make a disguised opening panel consisting of an aluminum frame, a door, a magnetic lock, a design of hinges and nodes.

In order to open the invisible hatch, just click on its middle, after which the magnetic lock snaps open, releasing the door from the frame. With the details of the device of various plumbing hatches next articlewhich we advise you to read.

Installation of the hatch is as follows:

- Even at the preliminary stage, you should determine the location of the door.Usually it is located in the center of the box or partition, which allows you to better withstand the symmetry of the pattern when tiled.

- When installing the frame, it is important to leave a niche (on two or four sides), the size of which corresponds to the parameters of the hatch. After its construction, the frame is attached to the profiles using long self-tapping screws (special holes are provided for them). According to the instructions attached to the kit, the door and other parts of the hatch are attached to the frame.

- Next, the frame is sheathed with plasterboard sheets, which are overlapped on the hatch frame (it should also be attached to the cover with self-tapping screws).

- At the end of the work phase, drywall and the door are covered with a primer layer. After drying, the hatch and box are covered with tiles (monochrome or with a pattern). All seams between the tiles are covered with sealant, after which the structure is left alone for two days for final drying.

The final stage is the cutting of the hatch, which is performed using a sharp clerical knife directed at an angle of 45 degrees.

Useful device tips

When arranging the design, it is important to consider the following recommendations of specialists:

- If the box is designed to mask vertical pipes, marking should be carried out starting from the floor.

- Be sure to provide a door or hatch at the valve and water meter.

- Regardless of the material used for the device system, on its inner surface you need to apply an antifungal agent that protects against harmful microorganisms.

- In a bathroom with a high vapor content, it is highly advisable to avoid wooden structures: in this case, a metal profile should be preferred.

- For the device box it is impractical to use various types of particleboard, including waterproof boards, since this material swells under the influence of water vapor.

- When attaching the structure to the ceiling, the transverse parts are located at a distance of 30 centimeters from each other to ensure proper structural rigidity.

- With closely located pipes it is better not to erect separate boxes around each of them, but to create a single design for the entire communication system.

It is important to make sure that the box does not touch communications: the minimum distance of the casing from the pipe should be 3 centimeters.

An alternative to the box-partition can be roller shutters. They give the interior a stylish look and also provide full access to pipelines.

Options disguise pipes in the toilet are given in an article fully devoted to this issue.

Conclusions and useful video on the topic

In the videos below you can see detailed instructions for the manufacture of boxes from the most common types of material: polymer panels and GKVL sheets.

Video # 1. How to close the pipes and installation with drywall:

Video # 2. Successful use of PVC panels:

With the right selection of material and the exact following of step-by-step instructions, even a novice master can create a comfortable and stylish design that fits well into the interior of the bathroom.

Tell us about how you built a pipe box in your own bathroom. Share useful technological nuances with site visitors. Please write in the form below, ask questions about controversial issues, publish photos on the topic.

Screen made of plastic pipes: types of partitions + step-by-step manufacturing instructions

Screen made of plastic pipes: types of partitions + step-by-step manufacturing instructions  How to make a chair from polypropylene pipes with your own hands: step-by-step instructions for manufacturing

How to make a chair from polypropylene pipes with your own hands: step-by-step instructions for manufacturing  Pipe Clamps: Species Overview and Installation Instructions

Pipe Clamps: Species Overview and Installation Instructions  Welding polyethylene pipes: a comparison of methods + installation instructions

Welding polyethylene pipes: a comparison of methods + installation instructions  How to arrange a pipe box in the toilet: an overview of the best ways to mask the pipeline

How to arrange a pipe box in the toilet: an overview of the best ways to mask the pipeline  Replacing Bathroom Tubes: A Step-by-Step Guide to Work

Replacing Bathroom Tubes: A Step-by-Step Guide to Work  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I completely remade the bathroom at home, and as a material for leveling the walls I used moisture-resistant drywall boards that are green. They are more expensive than usual, but there will be no need to redo them later in case of flooding. Completely demolished three walls: two external and one partition between the toilet and the bathroom. Made a combined bathroom, the space has become much more. He even moved the machine from the kitchen to the bathroom, and put a “dishwasher” in the kitchen. All pipes were also sewn with drywall. In general, I use drywall in everything and everywhere, the most universal means for installing partitions. Sometimes he even made a double layer so that the walls did not ring.

In my house, too, the pipes are closed with moisture-proof drywall, but such panels are only on one wall, because Such decoration makes it somewhat difficult to hang furniture elements on the wall, the same cabinets and shelves, for example. The inspection hatch is also in the same wall as the drywall; opens and closes by clicking on the desired point. Very convenient and beautiful solution.

And what about this box in case of a pipe leak? Throughout the entire length of the hatches do not. Disassemble each time?

If the box is long enough, it makes sense to make several technological hatches, in case of leaks. This will make it possible to quickly detect the area where the leak formed. But if the box is made of drywall, for example, then it will still have to be almost completely replaced, since water and moisture will damage most of the structure.

Providing technological hatches in plastic boxes is also a practical solution, but it will be superfluous along the entire length. Firstly, it is an extra waste of time and money, and secondly, to eliminate leaks, you still have to disassemble most of the structure.

Plastic and drywall have their advantages. For the first - this is ease of installation, for the second - this is the opportunity to implement any design solution. You can even lay tiles on drywall.