Do-it-yourself installation of plastic pipes: connection technology and wiring examples

Pipes from the symbiosis of metal and plastic are produced for the arrangement of intra-house highways. New products made it possible to assemble the water supply and heating system itself, without involving plumbers. Pipelines serve for a long time, they are extremely simple and quick to install, without creating problems even for inexperienced craftsmen.

Having completed the installation of metal-plastic pipes with your own hands, you can save a lot of money by saving the family budget for more important costs. To install them, the home master needs to stock up on only a simple tool to use, patience and knowledge that we are ready to share with visitors to the site.

We will tell you all about the specifics of using metal-plastic products and how to connect the pipelines assembled from them. The article describes in detail the negative and positive aspects of their use. Here you will learn how to install fail-safe operating systems.

The content of the article:

- Features of plastic products

- Technical characteristics of pipes D 16-20 mm

- Advantages and disadvantages of metal polymers

- Fields of application of metal-plastic elements

- Three main pipe routing methods

- Wiring diagrams for bathroom and bath

- Routing sewer pipes

- Rules for the installation of structures made of metal polymers

- Tools and materials for pipe laying

- Pipeline marking

- Overview of fittings for a metal-plastic system

- Conclusions and useful video on the topic

Features of plastic products

Metal-plastic (metal-polymer pipes) - composite products for the production of which various types of materials are used. Such elements have an attractive appearance, good wear resistance, elasticity, strength.

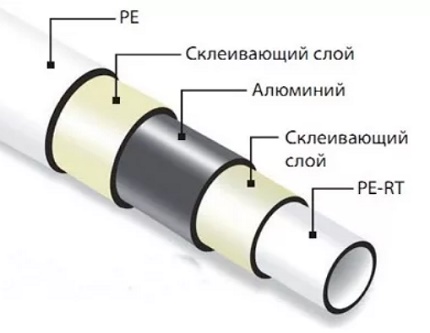

Typically, a pipe consists of five layers. A strong polymer, usually crosslinked polyethylene, is used as the carrier base. It gives smoothness to the inner surface, protecting it from blockages, and also contributes to the strength of the product.

An adhesive is applied to the core, on which an aluminum foil stabilizing the pipe is fixed (it also prevents oxygen from entering). The connection is fixed by butt welding or overlap.

The fourth layer also applies glue to which the outer coating is connected - white polyethylene, which provides protection to the product and gives it an aesthetic appearance.

Technical characteristics of pipes D 16-20 mm

Here are the data characteristic of metal-plastic pipes of widespread diameters (16 and 20 mm):

- The wall thickness is respectively 2 and 2.25 mm; the thickness of the aluminum layer is 0.2 and 0.24 mm.

- One running meter weighs 115 and 170 grams and contains a volume of liquid equal to 1,113 and 0,201 liters.

- The thermal conductivity coefficient is 0.43 W / m K, the expansion coefficient of metal-plastic is 0.26x104 by 1 degree Celsius, the roughness coefficient is 0.07.

- With a transverse break of the material, the strength coefficient is 2880 H.

- The bond strength of the adhesive layer with the foil is 70 H / 10 sq. Mm, the coefficient of strength of the aluminum welded layer is 57 N / sq. mm

- Plastic pipes can work even at +95about C, briefly withstanding temperatures + 110-130about WITH.

- In temperature limits from 0 to +25about C the system operates at a pressure of up to 25 bar, and at +95about C withstands pressure of 10 bar.

- The tightness and integrity of the metal-plastic pipe is broken at a load of 94 bar (at +20about WITH).

With proper installation and compliance with operating rules, products made of metal polymers can last 50 years or more.

Advantages and disadvantages of metal polymers

The advantages of such products include:

- ease of installation: the connection of various categories of plastic pipes is quick and easy;

- high heat resistance (water heated to 100 ° C can be transported);

- reasonable price (metal-polymer pipes are cheaper than metal and most plastic analogues);

- high strength, ring stiffness;

- resistance to corrosion, aggressive environments;

- unwillingness to form deposits and blockages;

- aesthetic appearance;

- high throughput;

- low thermal conductivity;

- sufficient ductility;

- easy repair;

- durability.

The main disadvantage of such products lies in the fact that the metal and plastic of which the pipes are composed have different expansion rates. Regular temperature differences of the agent located in the pipes can lead to weakening of the fasteners, as a result of which leaks occur in the structure.

To avoid this, experts advise, when installing, to always provide a certain margin at the joints of pipes. It will also be useful because metal-plastic systems do not withstand water shocks.

To evaluate the pros and cons of these pipes is simpler and easier in comparison metal-plastic and polypropylene products. A comparative review is given in our recommended article.

Fields of application of metal-plastic elements

Pipes made of metal polymers are widely used in the arrangement of individual houses, in industrial construction and agriculture.

The main areas of their use are:

- transportation of liquids, gaseous agents;

- laying of drainage systems, water supply systems, heating;

- in designs involving the transfer of compressed air;

- connection of heating components to radiators, floor heating device;

- installation of conditioning circuits;

- protection and shielding of wires (primarily power);

- construction of irrigation systems.

Metal-plastic is not recommended for use:

- in the organization of central heating systems with the proposed arrangement of elevator units;

- in places with the assigned fire safety level “G”;

- when the expected flow of hot fluid in the pipeline with a working pressure> 10 bar;

- in rooms where it is planned to place sources of thermal radiation with a surface temperature of more than 150 degrees C.

In addition, metal-polymer pipes are undesirable to use in safety, signal, overflow, expansion circuits and in fire water supply systems.

Three main pipe routing methods

The wiring of metal-plastic systems can be carried out by different methods, each of which is selected based on the feasibility and possibilities of further access to the system.

Option # 1: Hidden

In this case, all pipes and joints are hidden in the depths of the wall under the finishing materials. Only fittings and bends for connecting plumbing devices are brought out.

When using this installation method, the interior design is preserved, in addition, masking communications protects them from accidental damage.

This option has several disadvantages:

- For laying channels under the pipes, a complex and laborious process of gating is required.After laying communications, the surface has to be restored again.

- A similar method is not suitable for load-bearing walls, where it is forbidden to carry out gating with regulatory documents.

- Fairly high cost associated with additional work.

This method is best used during repairs in the bathroom. It is not advisable to arrange a hidden gasket in an already decorated room, since this will require the complete dismantling of the wall covering (cladding, plaster).

Option # 2: open

If the pipes cannot be hidden in the wall for any reason, they can be laid along its surface. This option is more convenient for visual inspection of the joints, which allows you to quickly clean the area or replace a component if necessary.

Open wiring can be used in rooms that have already been repaired, since installation will not harm the design of the walls. The advantages of this method include its ease and lower cost of work than when laying internal communications.

Option # 3: Combined

In this case, the pipes are held on the surface of the unfinished walls, after which they are closed with boxes or false panels. This is a rather complicated method, because it requires a perfect fit into the interior of decorative elements, which can also be used as drywall, tile and other materials.

Wiring diagrams for bathroom and bath

In plumbing work carried out in bathrooms and toilets, three schemes of wiring metal-plastic pipes can be applied. For private homes, the most rational is the use of a collector.

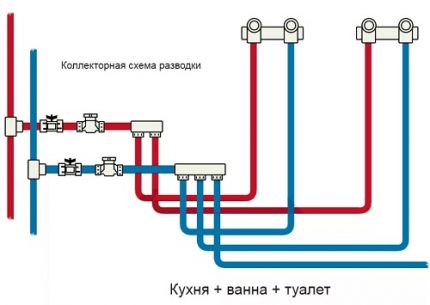

Efficient Collector System

A reliable and practical option, involving the connection of each object to the central pipe through a supply pair. This allows the faucet to regulate or turn off the water supply to each specific plumbing fixture.

All control devices are located in a compact manifold, which is placed in a specially designated space (cabinet).

Inlet pipes with a minimum of connections do not require special control, which allows laying in a hidden way. The disadvantage of this option is the rather high cost, since for each connection you will need to purchase a special shut-off valve. Since such a system is quite complex, work must be done carefully and carefully.

An important advantage: in the event of failure of a single item (washing machine, mixer), there is no need to completely disconnect the bathroom from the water supply - just turn off the necessary shut-off valve.

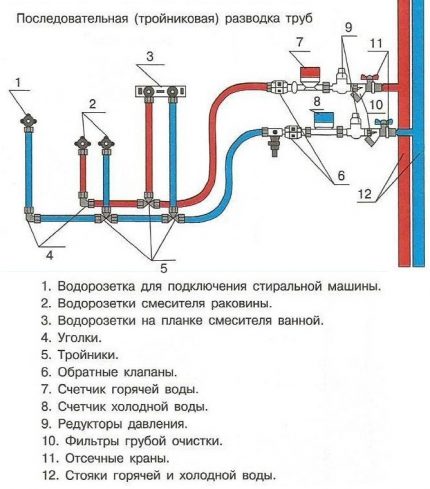

Serial connection system

This option involves connecting each plumbing item to the main pipe using a separate tee. It is more suitable for bathrooms with a minimum number of objects (washing machine, general mixer).

The sequential scheme can be implemented already after completion of the finishing work in the room using an open laying system.The assembly process is quite simple: the pipe is laid from one object to another, at the same time the inlet element is removed from the tee.

This option requires minimal financial costs. It should be noted that with a large number of points of fluid intake, the pressure may not be enough, and the system will function with difficulty or even completely fail.

Power Outlet System

The connection of plumbing devices is similar to serial, but sockets are used instead of tees. This scheme is usually used only in individual houses, since it requires the laying of pipes of large lengths, as well as the installation of an additional pump, which will help ensure the necessary water pressure.

When performing connecting work with plastic pipes, several important nuances should be taken into account:

- When designing, it is desirable to provide a minimum of connections.

- It is important to use a pipe and couplings made of the same material.

- For pipelines, it is better to use thermal insulation to prevent condensation from settling.

- It is necessary to provide free access to metering devices, filters, plug-in connections.

Compliance with the rules will create a reliable system that can last for many years.

Routing sewer pipes

The installation work of sewer metal-plastic pipes has its own characteristics.

In this case, for the unhindered drainage with the prevention of blockages, it is important to observe the following requirements:

- Maintain a slope (0.02-0.03 from the integral length of the structure) towards the drain manifold.

- It is forbidden to place bends at an angle of 90 degrees when installing structures.

- The need to install special tees with removable covers (revisions) in areas before turns, prone to the formation of blockages.

- When installing the system in a hidden way, it is important to leave inspection windows opposite the revision.

- When assembling the system, it is important to leave a reserve intended for thermal expansion of the product.

For the installation of sewage, it is necessary to use pipes whose diameter ensures easy passability of wastewater.

For toilets, it is recommended to use products with a diameter of at least 100 mm, for bathtubs and sinks - 50-75 mm are sufficient.

Rules for the installation of structures made of metal polymers

When laying metal-plastic systems, it is important to be guided by the following provisions:

- When concealed laying of pipelines from this material, it is important to provide removable shields (hatches), devoid of sharp protrusions. They provide access to compression fittings.

- It is important to lay systems through building structures using sleeves, the inner diameter of which is 0.5-1 cm larger than the similar pipe parameter. The gap that is formed between the elements must be filled with a soft non-combustible material, which ensures the movement of the pipe in the longitudinal direction.

- When laying metal-plastic plumbing or heating systems, it is important to prevent damage to the surface of the elements, including scratches or cuts. To unpack the bay, it is better to avoid sharp objects, and mark the structure with a pencil or marker.

- Installation of the structure can be carried out using supports or suspensions, which are usually present in the assortment of manufacturers of metal-polymer pipes. They help to fix the products to the wall, while metal parts are installed with gaskets made of soft material.

All stages of operations must be carried out carefully and accurately, since the metal-plastic elements are sensitive to ultraviolet radiation, mechanical damage.External installation of such structures is appropriate only in places where there are no such factors.

Tools and materials for pipe laying

For laying metal-polymer systems, a minimum of devices and materials is required, but it is better to choose high-quality devices and pipes.

Pipeline Mounting Devices

To create a structure made of metal plastic, a rather modest set of tools is enough: a pipe cutter, a simple bender, press ticks, sliding and cap keys.

It is advisable to stock up to separate measured pipe sections from the bay. pipe cutterdesigned for cutting plastic pipes. Since plastic is a fairly malleable material, it can be cut with a hacksaw for metal or even with a sharp knife.

However, the ideal perpendicularity of the lines, without which it is difficult to obtain a tight connection, can only be obtained using a special cutter.

Wrenches of various types are important for mounting and assembling threaded joints on pipe fittings. If absolutely necessary, you can do with one ring spanner, but for comfortable work it is better to use two ring spanners and one adjustable spanner.

The gauge is an important tool for creating an accurate and tight connection between the pipe and the fitting: it allows you to center the cut plane and chamfer the inside of the product.

The pipe bender allows you to change the configuration of the element, so that you can save on corner fittings. It is especially important to have this tool if the design involves a large number of angular mates.

Before starting work, we recommend that you familiarize yourself with the rules and specifics crimping metal-plastic pipes.

What materials will be required?

To lay the pipeline, it is important to stock up on the following components:

- pipes (bays, measuring segments);

- various options for fittings (contours, tees, corners), with the help of which individual sections of pipes turn into a single system;

- fasteners - collapsible clamps and clips, with which metal-plastic structures are fixed on the supporting surfaces, most often on the wall.

It is important to select all the necessary materials and tools in advance in order to then freely carry out all the work.

Introduces a range of metal-plastic products for the assembly of pipelines this article.

Pipeline marking

Before starting work, it is important to consider how the pipes will be placed.

When developing a scheme, it is desirable:

- To put the pipeline lines directly on the walls of the room where it is planned to lay it, which contributes to the visualization of the structure.

- As a starting point, use the place where the pipe is connected to the tap or radiator, which must already be installed before installation.

- Minimize the number of tees and crosses affecting the stability of pressure, as well as minimize the number of other fittings.

- For corner laying of metal-plastic pipes, you can use a pipe bender or corner fittings.

- All connecting elements should be freely accessible, since the fasteners on the thread require periodic tightening to prevent leaks.

The installation of the connecting elements must be carried out after the completion of calculations and marking of the structure.

Overview of fittings for a metal-plastic system

To prepare for work, it is important to cut the pipes into sections of the required length, while all cuts must be performed strictly at right angles. If the pipe is deformed during the cutting process, it must be leveled with a caliber (it will also help to remove the inner chamfer).

For the installation of structures, various types of fasteners - fittingsdwell on them separately.

Option # 1: collet

Collet fittings, consisting of a body, a compression ring, a rubber gasket, have a detachable design, so they can be used several times. Carving parts allows you to combine them with household appliances.

To connect the connecting elements to the pipe, you need to put on the nut and ring in series. Insert the resulting structure into the fitting, tighten the nut. To make the pipe easier to pass into the connecting element, it is desirable to moisten it.

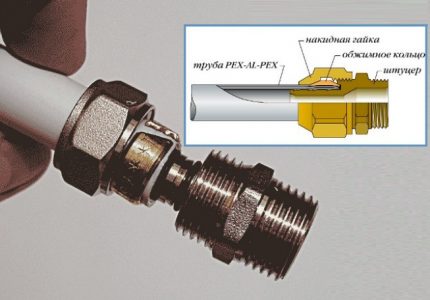

Option # 2: compression

Widely used for connecting pipes parts that can be called conditionally split. Before installation, it is important to ensure that there are o-rings and dielectric gaskets that must be on the shank of the part.

To connect to the end of the pipe, a nut and a crimp ring are put on (if it has the shape of a cone, the process is carried out from the narrower side of the part). After this, the shank is inserted into the pipe (for this you need to apply some force), while in order to seal the part is covered with tow, linen, sealant.

The next step is to attach and tighten the union nut to the fitting body. It is convenient to do this with two keys: one of them fixes the part, the other tightens the nut.

This method is quite easy and does not require the use of special equipment, however, it is undesirable to use it for hidden wiring, since it requires a connection check.

Option # 3: push fittings

Convenient connecting elements, for the fastening of which special tools are not needed. For installation, it is enough to insert the product into the connecting part, while the end of the pipe should be visible in the inspection window.

Immediately upon completion of installation, thanks to the included stream of water, the fitting wedge is pushed forward, forming a clamp that prevents leakage.

This method allows you to quickly and easily create the necessary design, ensuring high-quality durable joints. Almost the only drawback of push fittings is their high cost.

Option # 4: press fittings

These elements are used to create one-piece joints using press tongs or similar devices.

For connections via press fittings you need to calibrate the part by removing the fez from it, after which a sleeve is put on it and the fitting is inserted. The sleeve is captured by press pliers, after which, by moving the handle, the part is firmly clamped.

Such an element can be used only once, but the fasteners mounted with it are quite tight and reliable, making them suitable for hidden wiring.

Press fittings are installed in the following order:

Installation of pipes from different types of materials

To connect the elements, one of which is made of metal and the second of metal-plastic, special fittings are designed, one end of which is equipped with a thread, and the second - a bell.

For installation, the metal pipe must be threaded, wrapped with tow, greased with soap or silicone, and then hand threaded fitting. After its second end is connected to the plastic element, the thread is completely twisted with a wrench.

Assortment of fittings of various shapes

For ease of installation, the connecting elements can have a different shape. The most common are:

- adapters for connecting pipes with different diameters;

- tees providing branches from the central pipe;

- corners for changing the direction of flow;

- water sockets (adjusting knees);

- crosspieces allowing to organize various flow directions for 4 pipes.

A special configuration (couplings, triangles, tees) can have press fittings.

Conclusions and useful video on the topic

In the video below, plumbers will tell you how to correctly and quickly mount structures from metal-plastic pipes:

Using the right methods and quality components allows you to create durable metal-plastic systems that will serve for a long time without leaks, repairs and unnecessary material waste.

You can talk about how you installed and connected metal-plastic pipes in the block located below. Please comment on the information provided by us. Ask questions, share useful information and thematic photos.

DIY copper pipe installation: copper pipe installation technology

DIY copper pipe installation: copper pipe installation technology  DIY installation of polypropylene pipes: technology for working with PP piping

DIY installation of polypropylene pipes: technology for working with PP piping  DIY welding technology for polypropylene pipes: an overview of methods and nuances

DIY welding technology for polypropylene pipes: an overview of methods and nuances  Press fittings for plastic pipes: types, marking, purpose + installation example

Press fittings for plastic pipes: types, marking, purpose + installation example  DIY installation of HDPE pipes: welding instructions + how to bend or straighten such pipes

DIY installation of HDPE pipes: welding instructions + how to bend or straighten such pipes  Installation of a water supply system from polypropylene pipes: typical wiring diagrams + installation features

Installation of a water supply system from polypropylene pipes: typical wiring diagrams + installation features  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I won’t say about heating, but I managed to make a water pipe with my own hands using plastic pipes. I did not have much experience, but decided to try it. I laid pipes on top of the wall, but all the connections are visible, you can immediately install the leak and generally the open wiring is good because you can immediately see the problem area. Measured the required number of pipes took a pipe cutter, sliding and spanner wrenches and collets. It turned out pretty well.

And I was just in my private house heating with the help of plastic pipes, everything worked out fine for me. Pipe routing came out combined, because in places I had to hide them. Installation is not difficult with a pair of keys, an expansion tube and a pipe cutter. Here, however, for reliable tightening of the fittings, I recommend using a plumbing thread. Or what do you think can be used as a winding yet?

Hello. Previously, they always wrapped a linen tow soaked in oil paint. It is now considered not very reliable, they buy pastes special for impregnation. Although we have 8 years of such connections and do not flow. Now, in addition to the sealing thread, it has become fashionable to use aerobic sealant.