Inserting into a pipe without welding: a review of the technology for mortise work

When assembling and connecting water supply systems or its diversion, it is often necessary to connect the pipes, and it is better to do this without the use of a welding machine. However, not all home masters are familiar with the specifics of such delicate work. Do you agree?

We will tell you how to insert into a pipe without welding when laying pipe structures. In the proposed article, all methods of making connections for pipes from various materials are analyzed. Based on our recommendations, you can create a strong, reliably cohesive knot.

The content of the article:

How to connect pipes without welding?

There are several ways to connect pipes to the main line without welding. Some of them are among the one-piece, which it is almost impossible to disassemble without destruction of the pipeline. Others are split joints that can be easily dismantled and, if necessary, reassembled.

The choice of option depends on what material the pipe is made of.

All pipe rolling is divided into two main groups:

- hard - pipes made of cast iron, copper and steel;

- flexible - products are made of polymeric materials (polypropylene, metal plastic, polyethylene).

The basis of this separation is the need to use a larger area of engagement at the time of joining parts of polymer structures. For comparison: the insertion of pipes made of metal can be performed in limited conditions, using the minimum area of engagement of the joined parts.

Profile pipe joint

The most affordable way to joint profile pipes is through the installation of mounting clamps. With the help of these simple devices it is convenient to assemble any type of small-sized metal structures, erecting canopies and shelving, greenhouses and fences, peaks and modular partitions.

The indisputable advantage of using fasteners is the ease of installation and the ability to disassemble the assembled structure an unlimited number of times.

To implement this method will require only three components:

- Cut to size pipe.

- The required number of mounting clamps.

- Wrench.

Crabs clamps can be “X”, “G” and “T” -shaped elements, with the help of which it is convenient to join straight pipe sections, angular structures and simultaneously connect up to four segments within the same assembly.

When assembled, they have the shape of a square or rectangle, the sides of which tightly encircle the joined parts of metal pipes.

Fasteners crabs should not cause special difficulties. Insert the chopped pipes into the clamp and fix the pressure sticks by tightening the bolts on the system to the power of anyone.

But this method can only be used for profile pipes with a cross-section of no more than 20 x 20 mm, 20 x 40 mm and 40 x 40 mm. In addition, the joining of elements can only be done at right angles.

It is possible to connect square pipes without welding by installing fittings of a given profile.

Fasteners in the form of fittings are of several types:

- Couplings - in the joints at straight sections.

- Crosses and tees - for installation in branching places;

- Elbows and turns - if necessary, change the direction of the pipeline.

With the help of fittings, it is possible to obtain fixed fixtures, the only vulnerability of which is only the susceptibility to corrosion, which is characteristic of the ends of the joined elements brought into it.

This situation occurs as a result of accumulation of condensate inside the fastener. It will cause rust, provided that the metal pipes are not treated with an anti-corrosion compound.

Methods of tapping metal pipes

The choice of the best insertion method depends on the type of pipes being installed and their operating conditions. Connection can be made at an angle of 90 and 45 degrees, placing them in a direction vertically up or to the side.

Threaded Docking Option

Through threaded connections assemble pressureless systems, for example, drainage systems made of steel and cast iron or chimneys made of stainless steel.

In most cases, the pipe thread is rolled on special equipment. But if desired, this procedure can be done manually using a cutting tool equipped with teeth - dies. To do this, cut the workpiece of a given length, making a margin for stock for the threaded part.

The work is performed in the following sequence:

- In the bench vice, pipe sections are strengthened, thereby eliminating the risk of rolling the workpieces.

- To facilitate the fixation of the die, the chamfer is removed from the outside of the workpieces at an angle of 45 °.

- A die is carefully baited onto the cleaned end of the pipe, carefully watching to prevent skewing. If such is found in the first circles, the die must be removed, the workpiece knocked, and the procedure started again.

- The bait die is gradually screwed onto the pipe. After several turns, you need to check the correctness of the cut using the level.

- Having performed pipe cutting to the required length, remove the tool by turning it in the opposite direction along the finished thread.

If the tool at some point stops turning, you need to make one revolution in the opposite direction and remove the stuck piece of chips from the thread, then continue to work. To simplify the work of creating a connection on the thread, it is recommended to lubricate the ends of the workpieces and cutting tools with machine oil.

In case you have to cut in conditions where the pipe is close to the wall, it is quite difficult to make a complete revolution of the tool around the pipe. Facilitating the task will help the use of die holders. They are equipped with ratchet gears.

Before tightening the threaded connection, it is important to make sure that there are no loose chips or burrs on the pipe ends. Tighten the thread with some effort.

With the methods of threading pipes for the device of the water system will introduce this article. We recommend that you read some very useful information.

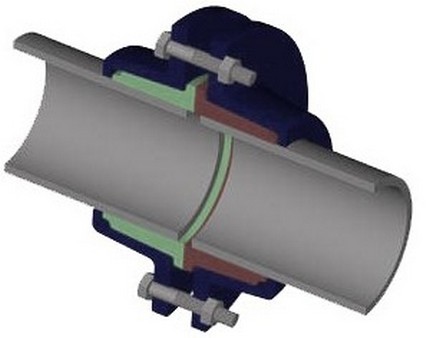

By installing a clamp

This connection method is chosen to create a detachable pipe connection in those cases when it is necessary to join the elements without welding and without thread. The clamps are flat rings with or without connecting protrusions, in which holes for studs and bolts are provided.

Assembly sequence for flanged assembly:

- In the place of the proposed tie-in, a pipe is cut, maintaining a right angle. There is no need to make a chamfer at the end of the pipe, just create the most even cut line.

- A clamp is put on the barbed section.

- To seal the joint, insert the rubber gasket so that it protrudes 10 mm beyond the cut line.

- A flange is pushed onto the gasket. It is connected to the mating part mounted on the end face of the second docked pipe, and fixed by bolting the bolts.

When tightening the bolts of the connecting clamps, it is important not to overtighten so as not to damage the fragile elements of the assembly.

Pulling should be carried out evenly, carefully wrapping the threads of the fasteners around the entire circumference. It is better to tighten the nuts of the mating parts of the clamp not sequentially, but in pairs. To do this, it is recommended to tighten the fasteners diametrically opposed to each other.

Installing a clamp to connect a communication line to it is as follows:

By mounting couplings

To obtain a tight connection of both pressureless and pressure pipelines, crimp fittings are used. Collets or compression fittings are equipped with compression rings, which are pressed “forever” during installation.

Couplings are conveniently used for joining pipes of different diameters and made of different types of materials. They are ideal for connecting plastic pipes to metal ones.

Insertion into the pipe using the coupling is performed in the following sequence:

- The ends of the pipes to be connected are cut strictly at right angles.

- A clutch is applied to the joint, placing it in such a way that the central part of the device is located strictly along the connection line.

- On pipes make marks indicating the correct position of the fitting.

- The ends of the pipes and the inner cavity of the coupling are treated with a liquid sealant.

- The end face of the first and second pipe is successively buried in the sleeve. Both workpieces are aligned exactly on the axis.

- When donning the fitting itself, they are guided by the previously applied markings.

During the connection of pipes to the external communication lines, mainly couplings with flange type of connection are used:

The connection using the Gebo coupling was also widely used. This compression fitting is equipped with clamping and sealing rings. Installation of the element can be performed without any special tools.

Work with polymer fittings

Tapping into a polymer pipe is even easier. One of the methods does not at all require complex and most accurate cutting of the pipeline. This is especially true if it is necessary to insert plastic elements of large diameters, which, under the action of the insert, can be deformed.

Insertion with installation of a branch pipe

To implement this method, it is necessary to purchase a pipe section equipped with a pipe in advance at a hardware store. The diameter of the workpiece should correspond to the cross section of the water pipe.

The finished blank will create a second wall of the pipe. In the workpiece fixed on the pipe, a hole is drilled with a core drill, the diameter of which corresponds to the size of the nozzle.

Liquid silicone sealant is applied to the inner surface of the mounted flange. The same composition covers the area around the hole, not reaching the 1 cm cut line. The prepared flange is mounted on the pipe.

To tighten the edges on both sides, two additional fasteners are used. Tighten them very carefully so as not to squeeze the sealant out from under the flange. The remnants of the glue protruding out are removed with a napkin.

If you have to insert on a plastic pipeline, the system pressure of which is minimal, instead of a collar, you can safely use a wide building tape.

Mounting adapter and saddle

For a tight and at the same time quick connection of the pipeline, it is convenient to use ready-made elements:

- Adapters - used for tapping pipes D 100-110 mm.

- Saddles - choose to insert thin pipes D 32-40 mm.

Nurses are two-piece crimp constructions that are convenient to install if necessary tapping on a non-disconnected system.

On sale there are modern models of the device, equipped with a heating spiral and a cutting mill, with which a hole is made.

Crashing into a pipe using an adapter is pretty simple. The work is carried out in several stages:

- If the pipe is connected to communications, block the water in the system.

- In the right place using an electric drill equipped with a crown, make a suitable hole.

- An adapter is installed on the prepared area, not forgetting to lay a soft rubber seal.

- Tighten the structure with bolts.

If no bolts are provided for in the design of the insertion element, construction sealant is used for fixing. For this, the composition is applied to a defatted surface. The nut is gently tightened, and the excess surplus funds removed.

The technology for inserting pipe branches into a plastic water main is devoted to this articlewhich we recommend for familiarization.

Connection of asbestos-cement pipes

Asbestos-cement pipe products, the material for the manufacture of which is Portland cement mixed with asbestos fibers in a ratio of 4: 1, are connected by installing couplings and fittings.

The choice of method depends on the working pressure in the system:

- For pipes with a working pressure within 3 kgf / cc, the insert uses asbestos-cement double-breasted couplings equipped with rubber seals. The lengths of 150-200 mm have a slightly larger diameter than the size of the connected pipe.

- For pressure pipelines with a working pressure of 3 kgf / cc, special fittings are used, referred to as Zhibo couplings. They are collapsible constructions with flanges and cast-iron bushings, supplemented with rubber sealing rings.

In both cases, the key role in achieving joint tightness is played by rubber o-rings.

The technology for inserting using couplings and fittings is the same as when working with metal fittings. The only thing - since asbestos-cement products are fragile enough, the insert should be performed with extreme caution.

The subtleties of the process of tapping into an existing water supply system under pressure are described in this articlewhich we advise you to read. It provides a step-by-step guide on how to make a complex connection.

Conclusions and useful video on the topic

How you can crash into a pipe without using a welding machine, you can see in the following videos.

Inserting into a plastic pipe by installing a coupling:

Insert option with ball valve installation:

There are many connection methods that are a worthy alternative to durable and reliable welding. The main thing is to competently approach the choice of the best option and make an insert, strictly adhering to the technology.

Do you want to personally share with you the well-known subtleties of performing tapping without welding? Have questions or photos of the mortise process? Please write comments and post pictures in the block located under the text of the article.

Replacing gas-fired heating batteries: a review of technology

Replacing gas-fired heating batteries: a review of technology  How to crash into a plastic pipe: features of work and analysis of all important nuances

How to crash into a plastic pipe: features of work and analysis of all important nuances  Soldering polypropylene pipes: work rules and analysis of possible errors

Soldering polypropylene pipes: work rules and analysis of possible errors  DIY welding technology for polypropylene pipes: an overview of methods and nuances

DIY welding technology for polypropylene pipes: an overview of methods and nuances  Press fittings for plastic pipes: types, marking, purpose + installation example

Press fittings for plastic pipes: types, marking, purpose + installation example  Pressure testing of metal-plastic pipes: the order and nuances of the work

Pressure testing of metal-plastic pipes: the order and nuances of the work  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

For my private home, I use non-welded pipe joints with split joints. Although this leads to leakage and leakage over time. But this type of connection, in my opinion, has a number of advantages over the non-separable design and the connection of pipes by welding. In case of damage, the part can be replaced without dismantling the entire structure. Connecting pipes with split joints is basically simpler than welding. As absolutely accurately noted above, there are many ways to reliably connect pipes without welding!