DIY welding technology for polypropylene pipes: an overview of methods and nuances

Want to repair or replace communications made of polymer pipes? Agree that it’s not bad to save on the call of the master by assembling a new pipeline yourself. But you do not know how you can connect the individual elements of the system among themselves and what is needed for this.

In our article, the technology for welding polypropylene pipes is described in detail - any novice plumber can connect them with their own hands. We will tell you what to consider, how to use a soldering iron to dock plastic elements. Let me show you in which cases other methods are used.

To help the novice master, we selected detailed video clips demonstrating the step-by-step process of welding polypropylene, and photo illustrations.

The content of the article:

Pipes and assembly accessories

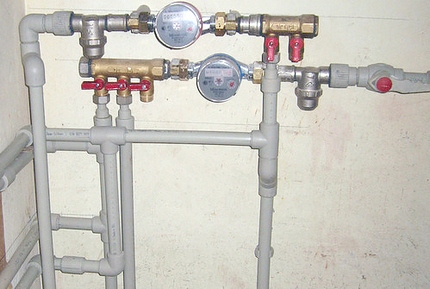

One of the indisputable advantages of polymer pipes is ease of assembly.

Installation of elements can be done almost everywhere: laid openly on walls or placed hidden under the floor.

Polymer pipes are available in diameters from 20 to 110 mm. For household purposes, products most often used are 20/25/32/40 mm in size. The field of application determines the indicator of the nominal pressure of the material.

In the marking, it is indicated by the letters "PN":

- PN 10 - choose to equip cold water supply.

- PN 16 - used for cold water, but with a higher pressure, as well as in the arrangement of the "warm floor" system.

- PN 20 - products, the only limiter of which is the temperature regime of liquids transported through them. It should not exceed 75 ° C.

- PN 25 - universal products used for arranging both “cold” and “hot” systems, the temperature of which reaches 90 ° С.

On sale you can find polymer products equipped with additional reinforcement.

The main feature of polymer pipes is the impossibility of bending them.

Therefore, all changes in the trajectory of the laid highway are carried out only from straight sections interconnected by auxiliary fittings:

- crosses - for the possibility of branching the main stream;

- tees - stream multipliers;

- couplings - for connecting pipes in a straight section;

- bends - for changes in the direction of the pipeline.

The fittings can be equipped with an embedded metal thread, which makes it possible to connect the polymer pipeline with metal elements.

When choosing auxiliary elements, two parameters should be taken as a basis: the internal section of the products and the thickness of their walls. These parameters should correspond to the technical characteristics of the polypropylene pipes used.

Methods of joining polymer pipes

When joining pipes made of polymeric materials, depending on the installation conditions, one of two methods is used:

- Soldering - involves heating and joining the molten ends of the elements.

- No soldering - involves connecting pipes by means of compression fittings or by implementing the so-called “cold” welding.

The second installation method is convenient in the sense that for its implementation there is no need to use special equipment. All work can be done using a simple tool - a crimp key.

A polypropylene pipe with a wall thickness of more than 4 mm and a diameter of more than 50 mm is connected using the butt welding technique:

Connection tools

The main tool used to connect plastic pipes is an iron for welding. This is a kind of soldering iron, powered by a 220V network. The principle of operation of the device is quite simple. The role of the heating element of the iron is performed by a welding heater, placed in a metal casing.

It warms up to a predetermined temperature the stove, which heats the nozzles. The temperature controller is responsible for maintaining the optimum temperature of the nozzles. Soldering and typical mistakes made when joining polypropylene pipes is devoted to next article, which we advise you to familiarize yourself with.

Included with the iron are heating nozzles of standard sizes. Heating up to a certain temperature, they soften the propylene to a viscosity that will ensure a tight connection of the elements.

Nozzles are selected depending on the diameter of the pipes used:

- The 20th size - for pipes with a diameter of half an inch;

- 25th - for products with a diameter of 0.75 inches;

- 40th - for elements with a cross section of 1.25 inches.

Since the cost of such a welding machine is quite high, and it is not necessary to use it so often already, it makes no sense to purchase equipment. It is better to rent a tool for a day or two.

For high-quality cutting and preparation of the welded sections, it is best to use a special tool designed for this - pipe cutter. With its help, you can get a smooth, smooth and beautiful cut.

For lack of a pipe cutter, work can be done with a grinder or a hacksaw for metal. The only thing - at the place of the cut after such tools, fringe remains. But it will not be difficult to remove it by stripping a strip of sandpaper.

In addition to the basic tools for the work, you will also need:

- square;

- building tape;

- a simple pencil or marker.

When planning to connect pipes using the cold welding method, it is necessary to purchase thermoactive adhesive made on the basis of polyester or epoxy resin or its thermoplastic analogue made on the basis of rubber in advance.

The main stages of soldering technology

The key conditions for a successful installation of plumbing or heating system of polymers are a careful calculation of the required material and well-made welding of elements.

Stage # 1 - calculation of material and components

To facilitate your work, thereby minimizing installation errors, the first thing you need to do is draw a diagram of the future system, indicating the number of turns and branches on it. When calculating the number of pipes, 25-40 mm spent on “penetration” should be added to each length of the segment.

If you have not yet had to weld polypropylene pipes, experienced specialists recommend that you even purchase several pipe sections for preliminary training. Such costs will come at a low price and will avoid gross errors during the installation of the system.

Feature polypropylene pipes is an increase in the coefficient of linear expansion under the influence of high temperatures.

As a result: when heating or increasing pressure inside the system, the pipes lengthen and begin to sag over time. To prevent this phenomenon, when laying sections longer than 4-5 meters, it will also be necessary to use compensators.

Compensators are installed both on horizontal and vertical sections, mounting them between two fixed supports. If necessary, it is possible to purchase compensators of a special modification, which can eliminate linear expansion at the angular bends of the pipeline.

We will find out how to properly weld polypropylene pipes so that there are no leaks at the joints.

Stage # 2 - soldering pipeline elements

Briefly the essence of welding technology polypropylene pipes lies in the fact that under the influence of high temperature the ends of the docked elements are heated and by tight pressing against each other are connected.

Before starting work, pieces of pipes cut to the specified length eliminate bumps and burrs. If a layer of internal or external foil is provided in the pipe, it must first be cleaned with a crosscutter equipped with well-sharpened and adjusted knives.

When performing stripping using a crosscutter, the pipe must be deepened into the tool until it stops.

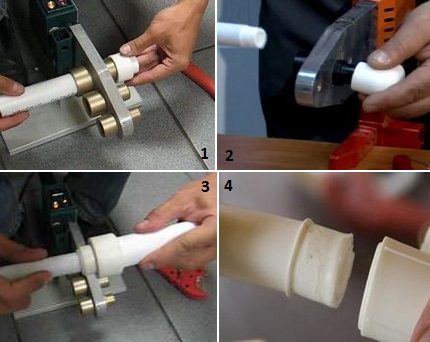

Do-it-yourself plastic pipe welding work is performed in the following sequence:

- Connect soldering iron for PP pipes to power supply in order to warm up the equipment to the optimum temperature of 260-270 ° C.

- The pipe segments to be joined are simultaneously put on the nozzles, ensuring the most even entry. This work should be done quickly and confidently.

- Having withstood the time specified in the instructions until the fittings and pipe ends melt, they remove the elements from the heating nozzles.

- Dock the molten ends together, gently squeezing each other for 15-20 seconds.

- Bonded parts are left in a static position so that the seam cools completely and the joint becomes monolithic.

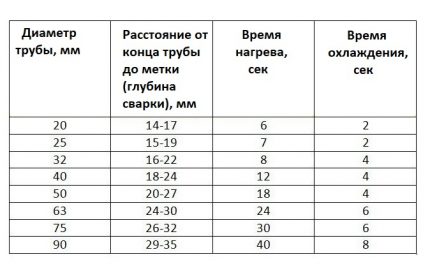

You can determine the duration of heating from the instructions supplied with the equipment or by using the table below.

It is impossible to neglect the requirements for heating time indicated in the table. Insufficient warming is not able to provide a reliable connection. Excessive overheating will cause the polypropylene to “leak” and the parts to deform.

As a result: protrusions are formed on the inner surface of the welds, which will significantly reduce the diameter of the pipeline.

After completion of polymerization and solidification, which takes about 20 seconds, the joint is ready. Using the same technology, all subsequent nodes are soldered to the bitter end, while the heating system or polypropylene water supply will not be fully assembled.

Temperature parameters soldering PP pipes are given in the article, which independent home masters should definitely familiarize themselves with before starting work.

Quick photo guide for welding PP pipes

The following selection of step-by-step photos will help to visualize the sequence of work on assembling a polypropylene pipeline and connecting its parts:

Typical installation errors

The main mistakes that beginners make when working with polymer products:

- Heating parts. At the time of heating, the parts should be located in the most even position. The slightest displacement can adversely affect the operational parameters of the entire plumbing system.

- Dock polymerized ends. When pressing the molten ends of the elements, you cannot rotate the parts around its axis. This can lead to the seam being not strong enough.

- Alignment. When joining the elements, only a slight adjustment of their alignment is allowed, the duration of the procedure of which is no more than 1-2 seconds.

Another important point: when soldering fittings with fittings, it is necessary to take into account the location of the valves, providing them with a free full stroke.

If after joining the elements as any kind of seam doubts arise, it is better to cut the joint and redo it.

It is better to eliminate defects at the stage of installation of the structure, since it is much more problematic to replace a leaking joint in a running system.

Assembly of elements without soldering

The use of compression fittings and modern adhesives makes it possible to carry out the installation of polypropylene pipes efficiently, quickly and with minimal material investment.

Option # 1 - installing a compression fitting

To implement this method of connection, you will need to purchase compression fittings and use a crimp wrench.

Installation of compression fitting includes three main stages:

- A blue nut is put on the end of the pipe cut off at right angles and deburred.When placing a white crimp ring, it is necessary to give it a position in which the thickened part is directed towards the tail of the pipe.

- The pipe is inserted into the fitting until it stops, pushing the clamping ring to the maximum.

- Tighten the blue nut, "baiting" it first by hand, and then booster with a key.

The assembly of compression fittings does not require special knowledge and skills. Products are delivered ready for installation for sale. Their installation can be performed under any temperature conditions.

Option # 2 - gluing elements

The adhesive method is used to assemble a water supply system, along which it is planned to transport only cold water. To apply the method of "cold" welding, you will need to use the "aggressive" adhesive composition type LN-915.

In order to protect the skin of the hands from accidental ingress of the composition and “corroding” of its active components, gluing procedures are best performed with protective gloves.

The sequence of actions when bonding products:

- Check the correspondence of the cut angles of the joined sections and mark the places for gluing with a pencil.

- The ends of the pipes to be joined are cleaned and degreased.

- An adhesive layer is applied to the ends of the pipes and to the area of the flares of the fittings in an even layer.

- Cuts of pipes are inserted into the holes of the fitting, focusing on the marks made in pencil. The structure is kept in a fixed position for three minutes, after which excess composition is removed with a napkin.

- The combined elements are laid out on a flat surface and left for 5-6 hours until completely dry.

Run water to check the quality of bonding is possible only a day after completion of installation.

When implementing this installation technology of PP pipes It is important to observe two basic conditions: temperature and humidity conditions. All work must be performed at an air temperature of +5, +35 ° C. When gluing in hot weather, work should be done as quickly as possible so that the glue does not have time to dry before installation is completed.

Conclusions and useful video on the topic

You can learn about the intricacies of the processes of soldering and gluing pipes from the following videos:

Video # 1. How to solder pipes:

Video # 2. Water supply assembly without soldering:

Work on self-aligning polypropylene pipes, even for a novice master, should not cause special difficulties. It is only necessary to clearly and conscientiously comply with all technological standards. And then the pipeline assembled by yourself will please you with trouble-free operation.

Please write comments in the block below. Ask questions about controversial issues, share information that may be useful to site visitors. Leave posts with your own opinion, post photos on the topic of the article.

DIY installation of polypropylene pipes: technology for working with PP piping

DIY installation of polypropylene pipes: technology for working with PP piping  How to make a chair from polypropylene pipes with your own hands: step-by-step instructions for manufacturing

How to make a chair from polypropylene pipes with your own hands: step-by-step instructions for manufacturing  DIY copper pipe installation: copper pipe installation technology

DIY copper pipe installation: copper pipe installation technology  Do-it-yourself installation of plastic pipes: connection technology and wiring examples

Do-it-yourself installation of plastic pipes: connection technology and wiring examples  The connection of plastic pipes with metal: an analysis of the best methods and mounting nuances

The connection of plastic pipes with metal: an analysis of the best methods and mounting nuances  DIY installation of HDPE pipes: welding instructions + how to bend or straighten such pipes

DIY installation of HDPE pipes: welding instructions + how to bend or straighten such pipes  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

This article will be useful for people who have never dealt with plastic pipes and how to connect them. I'm not new to this, but I have a question. There was a problem with autonomous heating. Sin to leak in the system.So, can a polypropylene pipe expand when the system heats up, but this happens not after 30-40 minutes, but after 3 hours? They say that it can, but I think this is a reinsurance of the manufacturer. Tell me.

Hello. First of all, I’ll tell you that you need to use reinforced pipes, which have a much lower coefficient of linear expansion coefficient. It is also worth considering the fact that PP pipes soften at + 140 * C, although it is stated that they can withstand temperatures up to + 170 * C.

For an illustrative example, I will attach diagrams and tables:

- with linear expansion coefficients;

- change in pipe length during heating from 0 to 60 * C (different materials);

- structure of the reinforced PP pipe.

This information will help you in resolving your issue.

Yes, with a regular threaded connection, it can be checked visually and, in case of a leak, tighten or tighten it yourself. But how to control the quality of welds when accepting work from a master? Who should make a complaint after the connection breaks in your absence and floods all the lower floors? Such work really needs to be done by yourself.

So the master himself must check the quality of the work done. To verify the reliability of all connections and the operability of communications, a heating system is crimped. The site has whole article about this.

Also, I recommend a similar procedure after replacing equipment, adapters, seals. And in general, check the heating system by crimping before each season so that there are no unpleasant surprises. In principle, an ordinary automobile pump for pumping tires, an adapter and a manometer will be enough for this.