Ventilation for a gas boiler in a private house: arrangement rules

The need to install a ventilation system applies not only to rooms in which residents spend most of their time - bedrooms, living rooms, kitchens - but also to non-residential premises. Ventilation is especially necessary if heating equipment is installed in utility rooms and boiler rooms.

Both for a safe life of people and for trouble-free operation of a heat-generating unit, a competently organized air exchange system is required. You will learn all about how ventilation for a gas boiler in a private house should be arranged from the article we presented.

We will tell you what to consider at the preliminary stage. We explain what should be done before installing the ventilation ducts, what rules to observe during the installation of the system. This information may come in handy if you want to do some of the work yourself, without the involvement of specialists.

The content of the article:

What is ventilation for?

Some owners of cottages and country houses doubt the need for ventilation or argue that an open window in the boiler room is enough to ensure air exchange.

However, keeping the window open all the time is impossible. Often, for a complete exhaustion of exhaust air, a mechanical exhaust hood is necessary, therefore, in addition to natural ventilation, it is necessary to install forced ventilation.

The gas exhaust system performs very important functions:

- Supplies oxygen in the amount necessary to ensure the fuel combustion process. As you know, oxygen deficiency is fraught with such consequences as a decrease in heat transfer, incomplete combustion or an increase in the amount of fuel required, premature wear of equipment, clogging of the chimney with soot and soot.

- Removes combustion products. Part of carbon monoxide can penetrate into the room even with the correct installation and operation of the chimney, and its critical concentration in the air is a direct threat to the health of people living in the house.

- Discharges gas in case of accidental contact with air. The possibility of violating the tightness of gas lines also should not be overlooked - rarely, but propane leakage occurs. The result can be either poisoning of residents, or a powerful explosion.

Only a well-designed ventilation system designed according to the requirements of SNiP can be protected from negative consequences when installing a gas boiler. Thanks supply and exhaust ventilation you protect the family from explosion, fire and poisoning, reduce the load on the boiler, reduce fuel consumption and increase the heat transfer of heating equipment.

Installation Requirements: All by Law

At installation of gas boilers, which became popular due to low-cost fuel, requirements are made both for the boiler house itself, if the unit is located in a separate non-residential premises, and for the selection of places for all elements of the ventilation system.

For units whose power exceeds 150 kW, a separate building is being erected or an extension to a residential building is being made. In the vicinity of the boiler room, through an adjacent wall, there should be a non-residential premises.

The ventilation and conditioning rules are set out in SNiP 2.04.05–91. The main requirement relates to air exchange, which must be performed in full at least 3 times per hour.

Be prepared for the supervision of representatives of the gas service, who will definitely check:

- the presence of a solid foundation and concrete floor;

- paved communications - water supply, sewerage, heating pipes;

- insulation of walls and gas vents to prevent freezing in the cold period;

- area - not less than 15 m³;

- ceiling height - 2.2 m and above;

- obligatory natural lighting - a window of at least 3 cm² for each cubic meter of boiler room volume.

To ensure natural ventilation, the window is equipped with a window, and a small clearance is left under the front door for free air flow - about 2.5 cm high. Instead of a slit, door perforation is used - in the lower part adjacent to the floor or threshold, several holes are made with a diameter of about 2 cm .

If the extension door leads to the house, or rather, to the non-residential room, then it is made of fire-resistant material with a high fire safety class.

For the cylinders, one more additional room is equipped, and they are connected to the boiler by means of a fuel supply pipe.

Chimney and ventilation requirements:

- gas outlet and air supply are carried out through separate channels;

- the size of the ventilation window for the air flow is not less than 1/30 of the boiler room area;

- the boiler is installed at a minimum distance from the outlet of the chimney and ventilation shaft;

- if a coaxial chimney is passed through the wall, then two holes will be organized: the first - directly for the pipe, the second - for maintenance.

Ventilation channels installed in a private house for outdoor or wall mounted gas boiler must always be open so that the air circulates continuously.

About types of ventilation in a private house

The induction of air exchange occurs in two ways: either by natural means, or by coercion.

A natural scheme is used if a boiler with a power of up to 30 kW is used when all installation requirements presented by the manufacturer are met.Providing ventilation for the operation of more powerful units is carried out by force, with the help of fans. Consider both ventilation methods.

Option # 1 - The Natural System

Less productive, but simpler natural ventilation is appropriate in small houses with low-power heating equipment. Often it is enough for air exchange processes occurring in basements, in attics, in sheds and garages.

Properly organized ventilation “captures” the entire air volume of the boiler room. For this, openings for air inlet and outlet are arranged at opposite points in the room.

For example, a boiler is installed directly in front of the door, and an exhaust hole is installed above the gas equipment. Air moves from below, moves through the whole room and rises up to the hood. The window in this case can be on any wall.

For the device of supply and exhaust ventilation in the boiler room of a country house You need to perform a number of actions:

- In the lower part of the door leaf, make several holes with a drill or a small crown. If there is a gap of 2.5 cm or more between the door and the floor / threshold, perforation is not necessary.

- Check if there is enough natural light to service the boiler and if the window opens well.

- To ensure a constant flow of air from the street, a hole with a diameter of 150-200 mm can be made in the wall. To do this, use a perforator or drill with a crown nozzle of the desired size.

- If a ventilation shaft is provided in the wall, install a decorative grill on the wall and make sure that the pipe brought to the roof is protected from rain and wind by a hood.

The hole in the wall also cannot be left unprotected - debris or rodents can enter the room through it.

The supply valves, which are commercially available, are initially equipped with additional means of protection - a grille, net or hatch, which is usually kept open.

An outlet is not recommended near the boiler. In the cold season, a sharp decrease in temperature can affect the operation of the boiler, therefore it is better to drill the wall at a distance of at least 1-1.5 m from the installation site.

If the boiler is installed in the kitchen, the exhaust duct is discharged into the ventilation shaft in the traditional way - through an opening located under the ceiling. Sometimes it’s just a pipe leading to the attic, and from there to the roof.

System ventilation ducts Is an example of a channel system. Canals can pass under a false ceiling, in niches and shafts.

In addition to pipes, gates, dampers, connecting elements, decorative grilles, air intakes, aerators are used.

A few tips for installing the duct:

The advantage of the sprayed insulation is in the possibility of applying it to already installed pipes. The process is quick and easy, and curvilinearly installed ducts and pipes located in hard-to-reach places can be insulated.

On the roof, the pipe is led to a height of 0.5-1 m above the roofing and is covered with a head - a special protective cap.

Responsible manufacturers of boiler equipment provide informative instructions for the installation and operation of units. In the technical documentation, you can find recommendations on the choice of ventilation systems indicating the technical characteristics of ventilation ducts.

Option # 2 - forced system

If natural air exchange is not enough to comply with the manufacturer's recommendations for the operation of the boiler, it is necessary to install a duct fan. However, the best solution is a combined system using filters, water heater and fans.

As a result of the operation of the ventilation system, air is pumped into the combustion chamber, and the combustion products are discharged at the speed necessary for air exchange.

Well-tuned ventilation, coupled with adjusted equipment, creates a microclimate in which fuel is saved and the efficiency of the entire gas heating system.

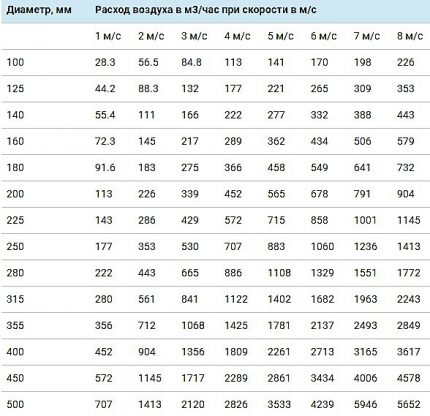

To choose the right fan, you need to consider its performance. Suppose that the boiler room is 10 m³. According to the requirements, for 1 hour in the room the air should change 3 times, that is, 10 x 3 = 30 m³ / h - the minimum fan performance.

You can use automatic adjustment, which includes ventilation equipment along with starting the boiler.

Coaxial chimney as an element of ventilation

Due to its design coaxial chimneys enjoy well-founded popularity. They are assembled according to the “pipe in pipe” scheme, which makes it possible to carry out two functions necessary for gas equipment at once: discharge of combustion products to the outside and air supply to ensure the combustion process.

Coaxial chimneys are divided into two types: horizontally and vertically located. The former are installed in the wall, the latter are led out through the ceiling to the attic, then to the roof. The vertical exhaust system is longer, more expensive, more difficult to install and requires the installation of a condensate collector.

To combat frost, the end of the pipe is equipped with a trellised head.

A few rules for the proper installation of a coaxial chimney:

- The pipe outlet is recommended to be equipped at a height of 2 m above the ground.

- The distance from the pipe to the window located on top is at least 1 m.

- The condensate collector is not necessary if the pipe is installed at an angle of 3-12 ° towards the street.

- It is forbidden to take the highway to the next room.

If a gas pipe is located near the chimney outlet, the distance between them should be 0.2 m or more.

The standard equipment of horizontal equipment consists of a pipe, a bend for connecting to the boiler, adapters, decorative pads, crimp rings, fixing bolts.

An example of installing a horizontal coaxial chimney going out through a wall:

The installation of a horizontal coaxial chimney is recognized as the easiest in terms of execution, therefore, it is recommended for self-installation. At the end of the work, the boiler is put into operation and the tightness of the connected pipe is checked.

Conclusions and useful video on the topic

Video # 1. How to provide all the nuances when installing a boiler room:

Video # 2. Learn more about installing natural ventilation:

Video # 3. Coaxial Chimney Overview:

The principles of a boiler room ventilation device for gas equipment are similar to equipping other rooms with air ducts, so for experienced craftsmen most of the work is quite affordable and feasible.

The most difficult stage concerns design and calculations - in order not to make mistakes, we recommend that you turn to heating engineers or qualified gas installers.

Please leave comments in the block form below, ask questions about interesting points, post a photo on the topic of the article. Tell us about how the ventilation system was arranged in your own boiler room. Share useful information that is useful to site visitors.

Basement ventilation in a private house: the best ways to arrange proper air exchange

Basement ventilation in a private house: the best ways to arrange proper air exchange  Ventilation in a private house through the pediment: arrangement options

Ventilation in a private house through the pediment: arrangement options  Attic ventilation in a private house: rules and devices for organizing air exchange

Attic ventilation in a private house: rules and devices for organizing air exchange  Ventilation of a septic tank in a private house: is it needed + tips for arranging

Ventilation of a septic tank in a private house: is it needed + tips for arranging  How to arrange ventilation ducts in a private house: design rules and construction manual

How to arrange ventilation ducts in a private house: design rules and construction manual  Underfloor ventilation in a private house: solution options and practical implementation methods

Underfloor ventilation in a private house: solution options and practical implementation methods  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Good afternoon! I have a gas boiler Navien 24k. A horizontal coaxial chimney is installed. A specialist from the fire department who came to get a certificate on the suitability of smoke and ventilation ducts demanded that an additional ventilation system be installed (a ventilation grill above the boiler and an insulated pipe on the roof wall).

I want to ask if his requirements are justified. After all, you are writing about a coaxial chimney as a sufficient ventilation method. Or am I misunderstanding something?

Good afternoon, Irina.

We are talking about general requirements for premises with installed gas equipment.

One of them is just the presence of natural ventilation, providing three-time air exchange per hour, plus the presence of easily discharged structures in the boiler room (window).

The order of the inspector of the fire service is mandatory.