Roof ventilation made of metal: features of the air exchange system

Any of the highest quality building materials eventually become unusable. Their service life is significantly reduced due to the constant exposure to aggressive factors, one of which is moisture. Metal-coated roofs are no exception, even if it is profiled sheet with a super-resistant polymer coating.

A competent device for ventilation of a roof made of metal and the organization of air exchange in a limited roof space will help to avoid operational problems.

We will tell you how to provide the structure with regular air circulation. We will show you how to exclude the formation and precipitation of condensate, divert atmospheric water if it enters the roofing system. Our recommendations will help significantly extend the life of the metal roof.

The content of the article:

Roof cake air exchange

Humidity in the area of the under-roof space can provoke rain and snow, brought under the roof by a strong wind. From the premises, the construction has a negative effect on household fumes. Wet insulation loses its operational characteristics, and then the crate and the wooden rafter structure begin to collapse.

Proper ventilation of the tiled roof cake prevents the negative effects of increased humidity. It will help to create a comfortable microclimate in the attic, in the attic and in the living rooms. It will protect the upper enclosing structure, its insulation system and the supporting rafter structure.

Most roof frames are constructed from lumber, which displays all the negative consequences of exposure to suspended water and precipitation. In addition, the insulation of the roof and the roof itself suffer from moisture, even if it is a metal tile, the service life of which, with proper installation, reaches half a century.

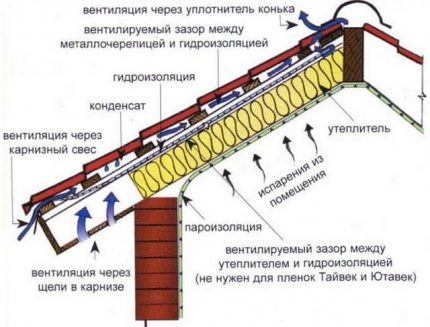

So, how to arrange the ventilation of the roof? A roofing cake consists of several layers, each of which performs a specific function. With proper installation, the combination of these layers will ensure the long-term operation of the building envelope, the roof and the system underneath.

The process of laying all materials, without exception, must be treated extremely carefully. Even if the roofing works are performed perfectly, and the vapor barrier, for example, is laid carelessly, this will entail the accumulation of steam with all the negative consequences: a decrease in the thermal insulation characteristics of the insulation, decay of the rafters and lathing.

Proper installation of a ventilated roofing cake

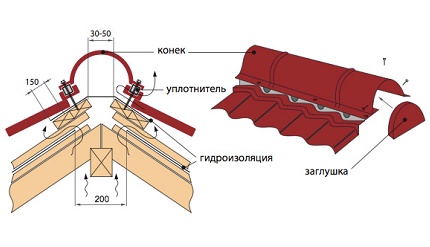

The roof ventilation system is a network of horizontally directed channels formed by a crate and a counter-crate. Channels called vents begin at the eaves and end in the area of the ridge. From precipitation, they are covered from above with metal bars of the ridge, grooves, and hips.

In hip and tent roofs, the outflow of air is slowed down due to the design specifics. To ensure proper ventilation of the roof in these cases, roof aerators are used. What is it and how to install them, we will consider below.

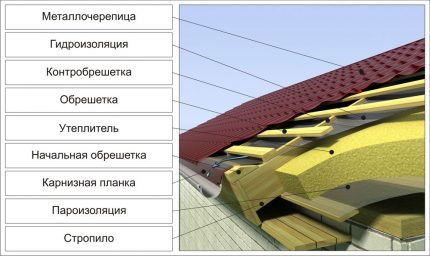

How to fit a roofing pie under a metal tile? First, between the rafters, a heater is laid by surprise.

At the stage of laying hydro and vapor barrier, it is necessary to provide for the presence of ventilation gaps:

- When laying conventional waterproofing films, 2 ventilation slots of 30-50 mm should remain: one between the film and the thermal insulation material, and the second between the roofing and the film.

- If a superdiffusion membrane is installed, the ventilation gap should only be between the membrane and the roofing material. The canvas is laid directly on the insulation.

- When laying a vapor barrier film, there should be a gap between the binder and the film.

All layers of the roofing cake are positioned so that from the outside, i.e. above the insulation, there was a waterproofing, but with an internal one, i.e. under a heater, - vapor barrier. The overlap between the sheets should be at least 150mm.

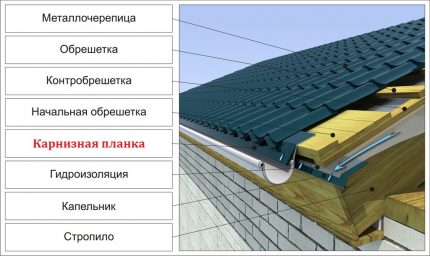

Then, the installation of the lathing for laying directly profiled metal roofing is carried out. Under the waterproofing film along the eaves, a dropper is installed to drive moisture from it. Before installation, the wooden crate must be thoroughly dried and treated with antiseptics and flame retardants.

After the installation of the crate is finished, a cornice is installed, covering the under-roof area from moisture. At the ends of the counter rails and the initial cornice board, a ventilation tape is attached with screws.

Ventilation elements can be:

- pinholes are holes with a diameter of 10 to 25 mm in the lower part of the cornice. The size of the point vents depends on the slope of the roof. The smaller it is, the larger the holes should be. Have holes under the gutters so that they do not icy. Outside, it is better to cover them with a fine mesh to protect against clogging with leaves;

- slotted - these are horizontal or vertical slits ranging in size from 2.5 to 5.0 cm.Slotted vents can also be covered with a ventilation mesh.

The air coming in through the eaves will move freely in the under-roof space and will be drawn out through the ventilated ridge (ventilation outlet).

The ridge is the highest structural part of the roof, also called the ridge ridge or rib. The ventilated skate is made in 2 versions: with slit-like products and with point ones along the entire length of the ridge. You can consider the option of a slit-shaped device for the entire length of the ramp.

For the roof of a complex configuration, grooves are necessarily arranged, they are also valley. This is an element for arranging a concave corner. A typical example is the junction of the main slope of the roof and a small slope of the veranda, dormer or entrance group.

Two slats are used in the gutter device: the first is laid under the roofing, the second is covered with a line between the adjacent planes of the slopes already covered with metal tiles.

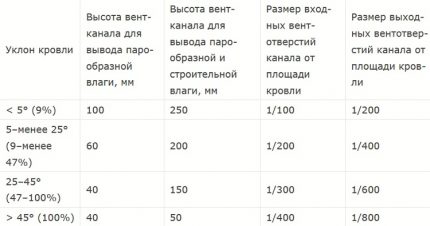

According to the collection of rules for the installation of roofs SP17.13330.2011, the sizes of ventilation ducts for flat and pitched roofs should be determined by calculation. However, the difference in the calculations made, even taking into account differences in climatic conditions and roof slope angles, slightly affects the result. Therefore, in most cases, take averaged values.

Many manufacturers of roofing materials also offer technical solutions for ventilation devices in the accompanying documents. And of course, conducting a regular audit (a couple of times a year) of the roof will help to decide whether to install additional ventilation devices or not.

Roofing aerators and fans

Additional elements of the roof ventilation system are roof aerators. They reinforce the movement of air masses many times. The aerator is a short pipe up to 50 cm long with a passage inside and deflector - a cap protecting the ventilation element from water and debris.

Aerators can be installed on a roof made of metal at any time: both during initial assembly and during operation. The shape and color can be selected according to the characteristics of the roofing material. Aerators are made of molded plastic, resistant to atmospheric effects, UV radiation, acids and even to short-term effects of fire.

The most effective elements for ventilation of the roof are considered turbine aerators. At the top of such a device is a deflector with a turbine.

The turbine blades rotate under the influence of wind. Natural traction in this case increases many times depending on the strength of the wind, reverse thrust completely excluded. The installation of such devices must be thought out in advance, since an increase in the size of the products (inputs) will be required.

When choosing an aerator for a metal tile, you need to pay attention to:

- the package included an installation manual, gaskets, mounting template, a through element, fasteners;

- the color of the device is selected to match the color of the metal;

- The quality of the material the aerator is made of must be documented.

It is not necessary to focus on the shape and type of the profile of the roof, becausethe flange of the mounting element for roof aerators and fans is made of material that, after applying little effort, exactly repeats the required relief.

If such systems are not enough for ventilation of a metal-roofing roof, roof fans are installed. These are aeration devices with an electric blade axial device located inside the pipe. The air speed in such devices can be controlled manually or set to automatic adjustment.

Installation of roof aerators

To choose the right equipment for roof ventilation, you need to consider:

- device performance;

- roof area, its shape;

- slope angle.

Metal roofing is certainly very vulnerable to moisture and especially needs to be protected from fumes from living quarters. There are no restrictions for the ventilation device, if the roof is covered with metal. The best option when the temperature of the air outside and inside the roof is different. Then active airing occurs spontaneously.

Aerators are installed at the end of the installation of the roof, for this:

- According to the template, a hole is applied to the roof.

- Cut the metal to the insulating layer with a jigsaw.

- The lower part of the pipe is covered with bituminous mastic, then is pressed against the base with force.

- The skirt (flange) of the nozzle with a protective casing is fastened with self-tapping screws.

How many aerators to put, each home owner decides for himself. Someone believes that for a hood for a metal tile, one pipe for 40 squares of the roof is enough, someone recommends that this amount be doubled. In fact, the calculation is verified in practice, according to the practical results of the efficiency of the ventilation system.

Roof ventilation with and without insulation

There are no technological features when installing roof ventilation systems of various shapes. In gable and single-slope, broken, hip and hip forms, the principles of ventilation are the same. Only the complexity of installation and the number of installed devices change.

Arrangement of a cold roof

In a cold attic, the under-roof space is blown with a large volume of air, so moisture does not condense. Air circulates freely through the eaves, skate, dormers, hip roof ridges and valleys.

In a gable roof, air enters through the eaves or openings in the gables. In stone gables, openings for air flow are made in the form of windows that open manually.

There are no gables in the 4-hipped hip roof. Here, the eaves overhangs with openings from 5 to 10 mm act as an air intake. Air exits through sloping hip ribs and dormers. If they are not enough for unloading, they put aerators and roof fans.

The problem areas of the pitched roof are grooves - snow accumulates in them in winter. Therefore, it is advisable to install point aerators or forced ventilation devices along the grooves.

Organization of ventilation of a warm roof

In the insulated roof between the roof and the attic there is a heat-insulating material on both sides covered by layers of hydro- and vapor barrier. If the roofing cake is laid in compliance with all norms, then the household rains from below and atmospheric moisture from above will not act on rafters, heat insulation and coating.

The classic ventilation scheme for insulated roofs is unchanged. Air is drawn in through the eaves overhangs and pushed out from under the ventilated ridge, valley and hip planks.Together with the air flows, household fumes escape, which partially penetrate the vapor barrier, condensate, which precipitates due to the temperature difference inside the attic and beyond, atmospheric water.

Installation of dormer and gable windows

Traditional way to air the attic - Installation of dormer and gable windows. Dormers are made on the slopes of the roof in the absence of a pediment. If there is a pediment, pediment windows are installed in it. Of course, ventilation is not the primary function of attic windows.

They are intended, first of all, to equalize the pressure in the attic space with the street during a gusty wind. If wind flows around the roof, the attic will have higher air pressure than the outside.

According to the laws of physics, this promotes the formation of a lifting force that removes the roof. Dormer and gable windows interfere with its formation, equalizing the pressure. Since no one wants the roof of the house to lie after the storm next to the house in the garden, dormer / gable windows should be done anyway.

The second function of attic windows is airing. For proper ventilation of the roof, only windows are not enough, but as an additional way to deal with condensation, they have proven themselves quite well.

The following types of attic windows are available:

- Pediments are the most common structures in gable roofs. Like all attic windows for space ventilation purposes, they should be located on opposite gables opposite each other. The geometric shape of the gable windows can be any.

- Dromers or cuckoos - decorative window designs located in the roof and protruding beyond it. Dromers are mostly decorative windows, nevertheless they do an excellent job with the functional tasks of dormer windows.

- Antidromeres - windows in the roof slopes not protruding beyond them, but rather slightly recessed in them.

- Skylights are flush with the roof slope.

All types of windows need careful waterproofing to prevent leakage. Dormer windows in the attic, depending on whether it is residential or not, can be glazed or remain open and are taken away by a decorative grille. Glazed windows provide the necessary ventilation only when the sash is opened.

For the installation of dormers, they sell ready-made kits with a box and a platband for exterior decoration of the installation site. Make boxes of windows for ventilation through the pediment made of plastic or wood. The configuration of windows can be absolutely any. In principle, at any time during operation of the roof, dormer or pediment windows can be cut through.

For the installation of the ventilation window in the gable insulated wall, an opening is cut equal in shape and size to the window box. The window is installed in the hole and closed with a casing.

In insulated gables, a place for windows must be foreseen and installed box. The box will ensure the correct installation of the frame, facilitate installation, and will resist the subsidence of the insulation.

To ensure regular air circulation, the windows on the pediments are mounted in such a way that between the lower window edge and the upper overlap line is not less than 80 cm and not more than 100 cm.

A more affordable and simple alternative to gable windows in concrete and brick walls are ventilation grids with a tube. They are installed even easier.

Puncher or machine tool with a drill, equipped with a diamond crown, in the opposite walls choose holes. A sealant is applied between the wall and the back of the grill. A vent tube is inserted into the hole to the grill. The grill is fixed.

Conclusions and useful video on the topic

The following video will introduce the nuances of organizing roof and roof ventilation:

Overview of flat roof aerators for tiling:

Video guide on arranging the passage of the ventilation pipe through the roofing cake:

For simple gable roofs, natural supply and exhaust ventilation of a roof made of metal is considered an ideal option, functioning almost without a glitch. In roofs of complex shapes, there must be ventilation holes and windows, since in the under-roof space there are many obstacles to the free passage of air.

In such cases, it is recommended to combine natural ventilation with the point installation of aerators. It is important to correctly install the ventilation system of the roof, since the life of the roof directly depends on its proper operation.

Please leave comments, ask questions, post thematic photos in the block form below. Tell us about how you provided the ventilation of your own country house or cottage. Share information that will be useful to site visitors.

Cottage ventilation: options for organizing an air exchange system + device rules

Cottage ventilation: options for organizing an air exchange system + device rules  Natural ventilation in a private house: rules for arranging a gravitational air exchange system

Natural ventilation in a private house: rules for arranging a gravitational air exchange system  Ventilation in the dressing room: options and methods for arranging the air exchange system

Ventilation in the dressing room: options and methods for arranging the air exchange system  DIY garage ventilation: an overview of the best options for arranging an air exchange system

DIY garage ventilation: an overview of the best options for arranging an air exchange system  Ventilation in a wooden house: rules for providing a log house with an air exchange system

Ventilation in a wooden house: rules for providing a log house with an air exchange system  Ventilation in the cellar: proper ventilation system technology

Ventilation in the cellar: proper ventilation system technology  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements