Requirements for laying a gas pipeline in settlements: depth and rules for laying an elevated and underground pipeline

Gas makes our life comfortable and convenient. But its improper consumption is fraught with danger, is not it? Nevertheless, negative consequences can be avoided easily. Why initially you need to comply with the requirements for laying the gas pipeline, and also do not forget about safety measures.

What are the requirements and what are the rules for laying gas pipes? We will talk about all this in detail in this article. We will provide the material with visual photos and useful video recommendations.

The content of the article:

What to consider when carrying out a gas pipeline?

The laying of any gas pipeline begins with the initiation of a number of responsibilities by the initiator. So, he must organize the work in such a way that during the construction and operation of the system of transportation of "blue" fuel was safe for people, their property, animals, environment. And also follow the rules for control gas flow.

Responsibility for violation of requirements

If you ignore regulatory requirements, then a person becomes a violator and there is a high probability of being punished for his actions. For example, get a fine for unauthorized connection to the gas pipeline.

Did not connect? But in order to get under sanctions for the indicated act, it is not necessary to hit the pipe, but it is enough to keep an incorrect record of the energy carrier consumption.

That is, it is enough to accidentally break, damage the counter or even a seal on it. And according to Art. 7.19 CAO for such an offense will have to transfer considerable 10-30 thousand rubles to the budget. But even more severe measures are provided for in Penal code. So him Art. 215.3 states that for unauthorized actions the fine may amount to 80-400 thousand rubles. And, if the acts caused the accident, then the contractor may well be imprisoned for an impressive period (up to 8 years).

We talked about fines for gas in more detail. this stuff.

As we see, the state takes gas pipeline construction seriously. As a result, before carrying out work, it is necessary to obtain appropriate permits. And the gasket itself should be entrusted to a company with a special license. The specialists of which will be responsible for the completeness and quality of pipe laying, which will help the potential consumer to avoid trouble.

Specialized regulatory framework

The main document regulating the creation of systems for the transportation of energy is SP 62.13330.2011. This set of rules is the current version of the demanded SNiP 42-01-2002. Both documents are called "Gas Distribution Systems".

In addition, the necessary requirements are contained in:

In each of the above documents, the characteristics of reliability, limiting states, and calculated values of loads are stated. This information is useful if you need to determine the wall thickness of pipelines or calculate the strength of the supports.

How to deal with corrosion caused by soil aggressiveness or stray currents is described in GOST 9.602-2005. If the pipes are laid above the ground, then you should familiarize yourself with the requirements SNiP 2.03.11-85. It describes how to properly protect the design of the pipeline from corrosion.

Features of choosing the type of gas pipeline

Before the construction of the highway, you should decide on the best option, suitable in specific conditions, and familiarize yourself with the rules for laying it. Since all this affects financial costs, efficiency and labor costs.

Since, first of all, the gas pipeline must be reliable, when choosing an option, it is necessary to take into account such moments as:

- corrosion activity of soils;

- building density;

- the presence of stray currents;

- terrain features;

- type of road surface if the gas pipeline crosses it;

- porch width;

- the presence of water barriers and many others.

In addition, you need to determine the type of gas that will be supplied. And also its quantity - volumes should be enough to satisfy the needs of all consumers.

Care must also be taken to ensure reliable supplies. In view of this, it should be remembered that an annular gas pipeline is preferable to a dead end or mixed one. For example, if gas is supplied to the so-called non-disconnectable consumer, then this option should be chosen.

All the points listed above cannot be ignored - each of them is indicated in the documents regulating issues related to the laying of gas pipelines. Among which SP 62.13330.2011 and others.

Also, we must not forget that the construction, modernization of any gas pipelines should be carried out in accordance with gas supply schemes. Which are developed at various levels - from federal to regional.

Therefore, before starting the design, the owner of the building, premises must:

- get permission for gasification in the city, district architectural and design department;

- apply in writing to the local gorgaz (raigaz) in order to obtain the so-called technical specifications, which is a set of information necessary to create a gas pipeline.

And only after that it is allowed to proceed to design. Which ends with an agreement in gorgaz (ryegaz).

Only after this will it be possible to begin laying the gas pipeline. Which, when ready, should provide consumers with the necessary amount of fuel and be safe.

The subtleties of laying a gas pipeline to a private house we described in next publication.

Routing in the village

Today, it is possible to provide a building (residential, industrial, any other) located in a city, village or holiday village with “blue” fuel in two ways: by laying underground (in demand in cities) or aboveground gas pipeline (most often used in small towns).

The first variety of energy transportation systems is traditionally considered more expensive. But horizontal drilling is becoming increasingly popular, which makes the construction of underground gas pipelines more affordable.

Laying their above-ground analogues is indispensable if there is no permission to perform work on other people's land plots and in a number of other cases.

Method # 1 - rules for the construction of underground networks

Although the creation of such a system is expensive, but in some cases its use is mandatory. For example, this happens if high-voltage transmission lines are located near the installation site. Or, when you need to cross the road (road, rail).

The depth of the underground gas pipeline under construction is indicated in the joint venture mentioned above. Where it is said that the distance from the pipe or protective case to the surface should be not less than 80 cm.

This means that the indicated value is relevant only for cases when the similar value is freezing depth for a specific region. That is, if it is more than 80 cm (for example, it is equal to a meter), then laying should occur at a depth of not less than 100 cm.

And also when preparing for laying, the following features should be considered:

- Pipe laying is possible at a depth of 60 cm, but only in cases when no transport drives over the place where the gas pipeline will be located.

- The presence of rocky soil in the place where the construction of the underground pipeline is planned is the reason for the creation of sand cushions. Thickness, which should be at least 20 cm. Therefore, the trench should become deeper by the specified number of centimeters.

The intersection of existing underground gas pipelines with any other utilities is allowed. But it is necessary to maintain the established vertical distance.

Which at the intersection should be:

- not less than half a meter for electric cables, any telephone armored cables;

- 1 meter for oil-filled electrical cables, the voltage of which is in the range of 110-220 kilovolts;

- from 20 cm - for water supply, sewage, gutters, unarmoured telephone cables, heat supply channels.

The distance between any power cables and other utilities can be reduced if they are laid in a protective case. The ends of which no less than a meter extend on both sides of the intersected pipeline.

But less than 20 cm between the gas pipeline and other communications with which there is an intersection, it should not be anyway.

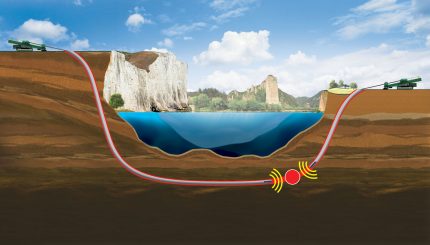

If there are collectors, heat supply channels, or any tunnels in the path of the gas pipe, the transition will be above or below them, then any kind of gas pipeline should be laid in case. In addition, additional weld inspection is required.

In this case, the protective case must be a pipe, the distance from the inner surface of which to the nearest point on the surface of the pipe with gas should not be less than 50 mm. That is, the diameter of the specified device must exceed the same parameter of the gas pipeline by no less than 100 mm. And when crossing the external walls of buildings, the difference can be up to 200 mm. In this case, the void between the case and the gas pipe is filled with bitumen.

The case serves to protect the gas pipe from mechanical damage, corrosion, and, as a result of exposure to aggressive soils, and from stray currents. Therefore, these devices are in demand, and their use in some cases is mandatory. For example, at the intersection of a gas pipeline with any utilities.

It should be remembered that any shut-off valves, as well as condensate traps, must be placed no closer than 2 m from the intersection of the gas pipeline with utilities.

It is allowed to lay two different gas pipelines in settlements with placing them in one trench. Moreover, they can be placed: nearby or one above the other. In this case, the exact distance between the pipes is not indicated, but the existing clearance should allow to perform all necessary work, for example, dismantling, installation, etc.

The laying of underground gas pipelines in channels, tunnels, and reservoirs is prohibited. But there is an exception - permafrost soils. It is permissible for them to lay pipes under roads (automobile, railway), the pressure in which will not exceed 0.6 MPa. The places of entry / exit of pipes from the ground must be enclosed in cases.

Method # 2 - the subtleties of laying pipes above the ground

In the case of the above-ground method of laying, the energy carrier is transported through pipes placed above the ground surface. Namely on heights up to 2.2 m.

What are used for:

- supports, and exclusively from non-combustible materials;

- building structures of various buildings and structures.

Moreover, as supports for the placement of gas pipelines can be used: columns, whatnots, overpasses, walls of industrial and other buildings, other designs.

A specialized joint venture regulates the issue of which buildings can accommodate gas pipelines and with what working pressure.

So, it says that:

- pipes for gas transportation, the pressure of which is not more than 0.005 MPa, are placed on the structures of residential, administrative, as well as household (non-production purposes) real estate;

- on the walls and roofs of industrial buildings, as well as boiler rooms of 1 and 2 degrees of fire resistance, as well as those related to fire hazard class C0 it is possible to place gas pipelines with a gas pressure of 1.2 MPa;

- on the walls of most other buildings it is allowed to place gas pipelines with a working pressure not exceeding 0.3 MPa.

We talked about pressure in gas networks of high, medium and low type in our other article.

Overhead installation of any transit gas pipeline in accordance with the design of administrative, public, domestic (non-production) buildings is prohibited.

Allowed one pipeline designed to transport gas to other consumers, placed on the walls of a residential building. This rule applies exclusively to low pressure gas pipelines. At the same time, its diameter should not exceed moderate 100 mm, and the distance to the roof should be less than 20 cm.

It is allowed to lay elevated gas pipelines on bridges made of non-combustible materials.

For transportation of energy is allowed to use mixed systems. That is, a part of the gas pipeline can be located in the trench, and if necessary, bypassing the barrier the pipes are taken out of the ground and placed on supports. If you need to cross the road, the pipes are again buried in the ground.

We recommend that you familiarize yourself withdevice underground and above-ground gas pipeline.

What pipes can be used?

Modern gas pipelines can be made of various materials, but only two of them are in demand: steel, polyethylene. Moreover, in the joint venture repeatedly mentioned, it is recommended to give preference to pipes made of the latest variety of material.

The reason for the demand for polyethylene pipes is that they are not affected by stray currents and are more resistant to corrosion. Due to which they retain their performance characteristics over the entire life cycle.

The listed features are important - they reduce operating costs and make the pipeline safer.

For comparison, steel pipes, according to the requirements of a specialized joint venture, should be protected from:

- underground (soil, soil) corrosion - This provision is relevant for all underground gas pipelines;

- corrosion caused by so-called stray currents - This rule applies to underground gas pipelines;

- atmospheric corrosion - The requirement applies to overhead gas pipelines.

Protection of pipes and other elements made of steel, the procedure is mandatory.

This is stated in SP 62.13330.2011which refers to:

- GOST 9.602-2005, which sets out the requirements for the fight against corrosion in the case of underground gas pipelines.

- SNiP 2.03.11-85 - This document contains the rules for the protection of elevated steel pipelines.

Each of the listed documents repeats the requirement that corrosion prevention measures are mandatory.

So in GOST 9.602. 2005 it is written that the laying of steel pipes of any gas pipeline is impossible if they are not covered with a protective layer, for the creation of which are used:

- bituminous mastics;

- coal mastics;

- polymer roll materials;

- polyethylene spraying.

To protect against stray currents use cathodic polarization. It must be completed no later than 1 month from the moment when the steel structural element was laid in the trench.

For overhead gas pipelines, the fight against corrosion should begin at the design stage. So in SNiP 2.03.11-85 it is said that even the construction of supports should be designed in such a way as to reduce the effect of moisture and its accumulation. It is also necessary to eliminate the accumulation and stagnation of aggressive gases.

And without all of the above, the gas pipeline will not be allowed to operate. That is, corrosion protection is no less important element in the creation of the gas pipeline than the depth of the trenches under the gas pipeline when conducting the pipe into a private house or any other building.

Conclusions and useful video on the topic

The first video will help you understand how gas pipelines are laid along the streets of settlements. And also to understand what horizontal drilling is:

This video material gives you the opportunity to learn about what problems they face when creating gas pipelines in cities and any other localities:

Gasification of buildings in a settlement or repair of an existing gas pipeline will make life more comfortable and safe. But such a result will be achieved only in cases where all the work (design, selection of components, laying, intersection with other communications and others) is done correctly. That is, taking into account the requirements of relevant guidance documents. Otherwise, troubles can be expected, including sanctions by the gas services.

Want to complement the above material with useful information? Or do you have questions about gasification of settlements? Ask them in the discussion of this publication - our experts and other visitors to the site will try to help you.

Laying a gas pipeline to a private house: methods, equipment, basic requirements

Laying a gas pipeline to a private house: methods, equipment, basic requirements  Gas pipeline looping: its functions and features of arrangement for a gas pipeline

Gas pipeline looping: its functions and features of arrangement for a gas pipeline  Is it possible to close a gas pipe with siding: the rules and subtleties of masking a gas pipeline

Is it possible to close a gas pipe with siding: the rules and subtleties of masking a gas pipeline  Elevated and underground gas pipelines: features of the device and gaskets

Elevated and underground gas pipelines: features of the device and gaskets  Requirements for installing a gas boiler in a private house: installation tips and rules for safe operation

Requirements for installing a gas boiler in a private house: installation tips and rules for safe operation  Requirements for the door to the kitchen with a gas stove: rules and regulations

Requirements for the door to the kitchen with a gas stove: rules and regulations  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements