How to make a septic tank out of rings with your own hands: schemes and options + step-by-step instructions

The construction of a country house is best to begin with the arrangement of sewers. You must agree that it is not an easy task to design and organize the proper disposal of wastewater on the site. We'll have to think carefully about the solution to this problem. After all, improper arrangement of the sewer threatens to make life in the house unbearable.

We will tell you how to independently create a functional septic tank on the site. So, among the affordable materials used in the construction of local treatment facilities, today the most popular are concrete rings.

It will be about how to build septic tanks from the rings with your own hands, and what to consider during the installation process. In addition, in the article you will find videos with the advice of experienced specialists, detailed instructions for installing a septic tank, as well as many useful recommendations about the sewage system in a country house.

The content of the article:

Septic tank from the rings: pros and cons

Concrete rings, which are the basis for the manufacture of walls of the structure, have high operational parameters.

Due to the technical advantages, the tanks built from them are distinguished by their strength and excellent resistance to aggressive environments.

Among the main advantages septic tanks made of concrete rings it is worth highlighting:

- Affordable price. Due to the low cost of the septic tank from the rings, the owners can afford to erect such a structure, even with limited material capabilities.

- Strength and durability. In terms of strength characteristics, concrete surpasses brick and is not inferior to natural stone.He is able to withstand strong pressure, he is not afraid of large volley discharges. And the service life of the structure can reach more than half a century.

- Tightness of tanks. The addition of properly arranged waterproofing makes the concrete ring construction resistant to groundwater from the outside and completely sealed from the inside.

In order to build a sewage system from the rings, you will have to spend much less money than to purchase the same polypropylene tank.

A septic tank made of concrete rings is not without drawbacks.

These include:

- Heavy design. Therefore, for the installation of such a multi-chamber design, it will be necessary to use special equipment or small-scale mechanization means.

- The likelihood of sewage entering the underlying soil strata. It occurs during the operation of the structure due to the appearance of cracks in concrete, as well as the destruction of the sealing of joints, which leads to the loss of its protective functions.

Before deciding on the arrangement of a local sewage system using rings, analyze the pros and cons of the material. And do not forget to evaluate your capabilities regarding the involvement of construction equipment.

Construction options

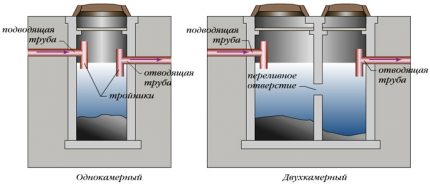

The design of the septic tank made of concrete rings is not difficult. It can be a two- or three-chamber structure. Single chamber drives operating on the principle of cesspoolsare used much less frequently.

Regardless of the type of construction, when servicing it, it will be necessary to attract sewage equipment. It will remove solid waste accumulating on the bottom and walls of the storage tanks.

Single-chamber septic tanks are selected when designing a sewer system for small seasonal dachas with a seasonal area, provided that the volume of wastewater is small. The good reasons for installing a single-chamber storage also include a high level of groundwater and the predominance of clay rocks in the geological section of the site.

Two- and three-chamber structures are installed when laying autonomous sewers for cottages designed for year-round use with large volumes of wastewater.

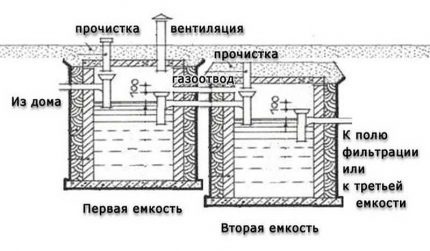

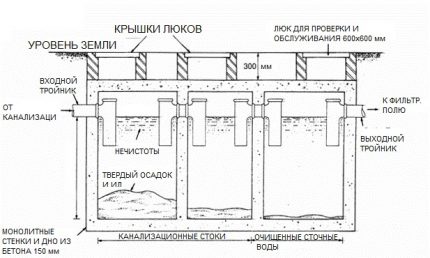

At arrangement of a two-chamber designsupplemented with a filtering well or a filtration field, the first compartment is a sealed container with limited oxygen supply.

It is equipped with a cast-iron or concrete hatch, as well as an inlet and outlet for drains. The second compartment for creating oxygen access conditions is equipped with a ventilation pipe.

During the construction of the purifier, including two or three tanks, the effluents will be subjected to multi-stage purification by sedimentation and filtration:

- In the first drive - the primary cleaning process is carried out, in which large suspensions are precipitated and decompose under conditions of oxygen deficiency, and the organics are processed by anaerobic bacteria.

- In the second chamber - the purification and filtration process continues, but with the participation of oxygen and aerobic bacteria. The decomposed organic residues in the form of sludge settle to the bottom, and the clarified liquid enters the drainage well, which is also absorbing or filtering, in the well.

After treatment, the water flows into drainage well, from where through holes in the walls and passing through the filter through the sand-gravel layer goes into the ground.

If the land is located on soils with good filtration properties that absorb and pass water well, and the groundwater level is not high, it is worth considering the option of equipping a septic tank, in which the clarified liquid is discharged into an absorption well.

In areas with a groundwater level of only 2.5 m, the process of ground cleansing is most often impossible, since there should be at least a meter between the bottom point of the drainage well and groundwater. In this case, it is better to drain drained septic tanks to drainage fields.

The arrangement of such systems requires large squares of space. But under given conditions, sometimes only such a system works.

Construction Location

When designing a septic tank, the sanitary zone is placed in such a way that organic waste cannot penetrate into drinking water and fertile soil. To do this, when choosing a place should be guided by sanitary and construction norms and rules.

The correct location of the cleaning system in the area is regulated by:

- SNiP 2.04.03.85. It spells out the rules for the construction of external sewage structures.

- SanPiN 2.2.1 / 2.1.1.1200-03. It lists the requirements for creating environmentally hazardous areas.

According to the norms, in order to avoid the foundation getting wet in case of emergency leaks, the septic tank must be placed lower than the house is located.

When choosing a place, it is worth considering the presence of ponds with running water, maintaining a distance of 5 m from them. The distance from trees should be 3 m, from shrubs - reduced to one meter.

You also need to know where the underground gas pipe is laid. The distance to it should be at least 5 m.

But keep in mind that directly above the place of deepening of the sewage treatment plant, machines should not be placed. By their weight, they can destroy the entire structure.

General installation rules

To create a strong and durable treatment design, it is worth following a number of basic rules:

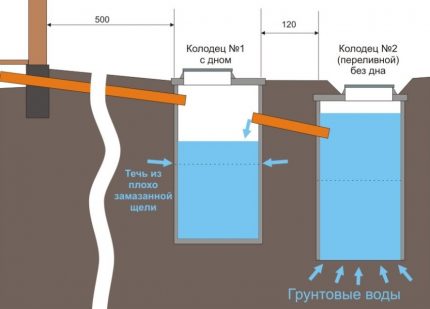

- The distance between the wells of the septic system must be at least half a meter. The gap filled with bitumen will act as a buffer when soil shifts occur.

- The presence of crushed stone or gravel-sand cushion. Such an interlayer will ensure the immobility of the structure even if the soil under the reservoirs “cools”.In addition, it is necessary for water drainage in case of leakage of wells.

- Do not neglect waterproofing. To seal the joints between adjacent rings, it is recommended to use several types of insulating materialsprocessing both the inner surface and the outer walls of the tanks.

The better the preparatory work will be carried out and all installation conditions will be carefully observed, the less often it will be necessary to call the masters to repair and clean the receiving tank.

Septic tank installation technology

There is nothing complicated in making a reliable and durable septic tank out of rings. When designing several compartments, the linear construction principle is used, in which all concrete columns of rings are built along one line.

The receiving compartment and the tanks following it are placed in close proximity to each other, and the filter column is located at a slight distance from them.

Step # 1 - measurement and design

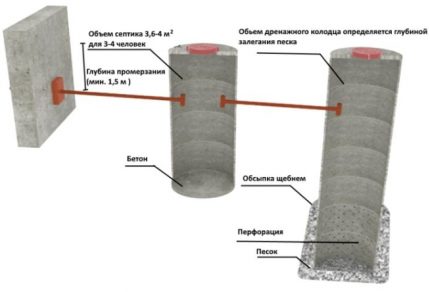

One of the prerequisites for effective wastewater treatment is the creation of conditions so that they are inside the walls of the septic tank for at least three days. Therefore, the dimensions of the chambers are determined on the basis of the total three-day volume of effluents.

According to the standards, the daily volume of water consumption per household, provided that household appliances are used, is about 200 liters.

So for a family of two or three people, the minimum volume of a treatment plant should be about two cubes. For a family of 5-6 households, a more capacious structure of 3-4 cubic meters will be required.

But when determining the volume of the structure, it is worth making a small margin. Indeed, in the event of the arrival of guests there is a risk of "overflowing" the norm. And eliminating the consequences is a rather complicated and at the same time expensive procedure.

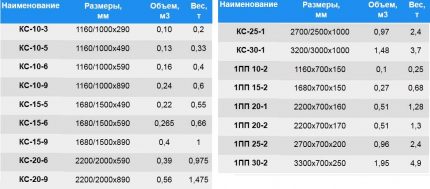

The table below will help you determine what size rings will be needed and in what quantity.

When choosing rings, take into account that the actual column volume should be clearly higher than the calculated one. This is due to the fact that the drains as they fill up only rise to the level of overflow holes and never reach the top edge. Therefore, the calculated volume of liquid should be placed up to the level of these pipes.

Step # 2 - preparing the necessary materials

At choosing rings for a septic tank it is advisable to buy products with locks. The presence of locks not only simplifies the installation process, but also prevents their displacement under the influence of frost heaving. When purchasing products, it is necessary to pay attention to the evenness of the seats and carefully examine the integrity of the locks.

In addition to the rings themselves from materials and construction tools, you will also need:

- sewer pipes;

- fine gravel;

- river sand;

- polyurethane foam;

- cement mortar;

- waterproofing compounds;

- rolled heat-insulating materials;

- building level;

- stairs;

- hammer drill;

- wide brush;

- container for mixing the solution.

To create overflows between wells, you will need asbestos-cement or polypropylene pipes marked "for external sewage».

The diameter of asbestos-cement or polymer pipes used for overflow should be 110-120 mm.

Step # 3 - digging the pit and arranging the bottom

Earthwork is best done after the first frost or in the hottest months. During this period, the lowest groundwater level is observed.

You can dig a pit manually by hiring a team of “diggers” for this, or by using the services of an excavator. If we take the costs of excavation, the costs of the digging team will be comparable with the amount that will go to the call of special equipment.

The dimensions of the finished pit should exceed the dimensions of the installed rings by 50-80 cm. This will simplify the installation process and allow external waterproofing of the joints of the structure.

When calculating the depth of the pit, three values are summarized: the height of the monolithic or filter cushion (20-30 cm) + the height of the rings (indicated in the table) + the height of the plate (15 cm).

The pit for the installation of the treatment plant should turn out to be two-tier: its second tank should be buried 50 cm lower than the first. Alternatively, dig a pit for each tank.

To bring the sewer pipes, they dig trenches, laying them below the depth of freezing of the soil. The width and depth of the trenches is selected based on the dimensions of the rings used for the construction of tanks. Most often they are made with a width of 50 cm with a depth of 1.2-1.5 m.

The bottom of the dug trenches should slope 2-3 cm distributed per linear meter. It is better to calculate in advance the difference between the extreme points by multiplying the distance between them by the slope declared by the standards.

Compliance with this condition will ensure gravity of the liquid. The flattened and tamped bottom of the trenches is covered with sand, forming a layer 10 cm thick.

The bottom of the pit is again carefully tamped. For concreting use a standard cement mortar, prepared in a ratio of 3: 1.

If you intend to install a bottom ring equipped with a bottom, concrete screed can not be built. In this case, it is possible to limit ourselves to crushed stone filling, having formed a layer 20 cm thick.

It is necessary to achieve an effect in which the pillow sags as much as possible.To thoroughly tamp the embankment and achieve maximum density, the tamper is alternated with filling the fill with water.

Step # 4 - installing rings and sealing joints

The construction of a septic tank begins with the installation of its closed part - the lower ring, equipped with a bottom. It is exposed exactly so that the walls are located strictly vertically. Compliance with this condition will ensure the strength and stability of the structure.

When using a ring without a bottom as the basis, the bottom of the pit must be pre-concreted. To do this, pour a concrete screed 30 cm thick. The dimensions of the concrete screed to be created should be 20 cm larger than the diameter of the immersed ring.

Concrete hardening can take up to two weeks. As soon as he gains the necessary strength, install the first ring. Putting the rings without help is almost impossible. This work is performed with two or three assistants.

To protect the structure from leakage and reduce the harm of groundwater to concrete, the joints between the base and the lower face of the ring are thoroughly coated with a waterproof cement mortar.

As waterproofing materials, it is perfect:

- bituminous mastic;

- deep penetration impregnation.

As an impregnation for processing concrete rings, it is good to use cement-based compounds such as Penetron or Aquacement.

For internal processing can not use toxic compounds. During operation, they can destroy the bacteria that are responsible for the decomposition of bio-inclusions.

On the first ring, all subsequent ones are installed in turn. To create a stronger fixation, metal brackets are installed on the outside of the structure. The “entry” points of the brackets are concreted and covered with a layer of insulation.

Dip the rings into the tank using a crane. The joints formed between the elements are also carefully sealed. The voids between the outer walls of the tank and the pit are filled with a mixture of soil, excavated by digging a pit, and sand.

"Pockets" should be filled up evenly, alternating compacting the soil composition with water filling.

The upper part of the structure, which is above the level of soil freezing, should be insulated. In severe frosts, the formation of an ice plug inside the reservoir is likely. And this significantly reduces the speed and efficiency of cleaning.

It is convenient to use as a heat insulator:

- stretches of polystyrene foam;

- finished products "shell".

In the upper part of the columns are mounted necks with holes for sewer manholes. They are equipped with concrete or cast-iron covers.

The second compartment of the purifier is equipped with a vent tube. It should rise above the ground by 70-80 cm.

Step # 5 - installation of overflow pipes

The location of overflow pipes is determined by the level of placement of the pipe leading from the house. Since the device of the overflow septic tank is designed to ensure the movement of fluid by gravity, the highest point of the sewer pipe should be placed below the level of freezing of the soil.

The overflow on the opposite side of the tank should be approximately 15-20 cm below the feed point.

To bring the sewer pipe in the wall of the ring using a punch, make a hole of the appropriate size. Fixing the pipe in concrete is easiest with mounting foam. It will retain moisture and act as a damper pad.

The pipe entry into the tank wall is carefully sealed. The inlet pipes coming from the house, as well as overflow pipes between the cameras, are equipped with tees.

Tees at the ends of the outlet and inlet piping will provide unhindered access for clearing blockages.

To increase the resistance of pipes to the most severe frosts, it is advisable to apply a layer of insulation on them, and close them with a protective cover on top.

Creating a filtration well

The filtering well can only be installed on a soil base that allows water to pass and absorb well. If sands, gravelly or gravel-pebble deposits are lying under its conditional bottom, then the disposal of treated effluents into the underlying soil layers will occur without any obstacles.

The absorbing well at 1 m is filled with a soil filter so that the fractions of the backfill decrease with height. First, the bottom is filled with sand - the thickness of the sand layer should be 30-40 cm, then a layer of fine gravel is formed - 30-40 cm.

The upper tier of the soil filter is usually larger crushed stone or gravel, and it is covered with a layer of 20-30 cm.

If it is planned to dispose of waste water not only through the bottom, but also through the walls, the bottom ring of the drainage well should be perforated. They install it according to the same technology as rings with solid walls. The voids between the walls of the pit and the concrete rings are covered with gravel.

If it is intended to construct a filtration field, perforated pipes are used. They are laid on a gravel-sand "cushion", which ensures the infiltration of treated effluents into the underlying soil strata, and on top they are covered with geotextiles and covered with earth.

How to save on construction?

If it is not possible to use special equipment during the installation and finances do not allow attracting a team of workers, try using such methods.

Instead of the traditional digging of the pit, followed by immersion of the rings in them, apply a technology in which the soil is removed gradually as the ring deepens. It is built on the fact that the ring under the influence of its weight falls down. The task of the master is to dig up the soil inside the ring and under its wall.

The concrete bottom in this case will have to be poured later. And it will be located exclusively inside the ring.

A significant disadvantage of the described method is the inability to perform thermal and waterproofing on the outer walls of the structure. In addition, due to the fact that the bottom is located inside the ring, the reliability of the structure is reduced.

In an effort to reduce the cost of the construction itself, the craftsmen propose a construction design that looks like a triangle.

By choosing this arrangement option, you will save space for the placement of rings and can significantly reduce the amount of land work.

But during installation, take into account the feature that the revision entrance in this design will be one in three rings. And therefore, all overflows should be placed outside the zone of its availability.

Conclusions and useful video on the topic

Option for arranging a two-chamber septic tank:

How to deepen rings without a tap:

In general, the installation of a septic tank from rings is not particularly difficult. It is only necessary to strictly adhere to technology and comply with safety rules. Due to this, the risk of wall collapse and their displacement will be reduced to zero, and the construction will last for more than a dozen years.

Have experience in arranging a septic tank from rings? Please share information with our readers or suggest your method of organizing an autonomous sewage system. You can leave comments in the form below.

How to arrange a septic tank from tires with your own hands: step-by-step instructions

How to arrange a septic tank from tires with your own hands: step-by-step instructions  How to make a two-chamber septic tank from concrete rings: a building instruction

How to make a two-chamber septic tank from concrete rings: a building instruction  Do-it-yourself monolithic concrete septic tank: schemes and rules for arranging a concrete septic tank

Do-it-yourself monolithic concrete septic tank: schemes and rules for arranging a concrete septic tank  How to make a septic tank with your own hands from barrels using plastic containers as an example

How to make a septic tank with your own hands from barrels using plastic containers as an example  Septic tank made of concrete rings: device, schemes + step-by-step installation process

Septic tank made of concrete rings: device, schemes + step-by-step installation process  How to make a septic tank from European cubes with your own hands: step-by-step assembly instructions

How to make a septic tank from European cubes with your own hands: step-by-step assembly instructions  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Although it is said that you can do it yourself, but there are so many nuances. The placement is regulated, it is necessary to consider the conduct of communications, and the general installation requirements must be taken into account. For such work, it is necessary to properly prepare, read, and it is better to deal with specialists. But the idea is excellent in its budget, but probably not for my site, which is constantly drowning.

Good day, Elena. In case of constant flooding, this option for arranging sewage will not work.

Pay attention to deep-septic tanks. Treated effluents up to 98% are allowed to be diverted into a ditch. When choosing, pay attention to horizontal models. They are most designed for installation in areas with high groundwater.

The proven Tver septic tank is a proven low-cost model. A detailed review is on our website. here.

ICE. This is where the table with ring sizes comes from? According to the formula V = p * R * R * H, the volume of the ring KS 20-9 is 890 mm * 2000 mm in size = 3.14 * 1 * 1 * 0.89 = `2.79 cubic meters, and you have only 0.59 cubic meters