Sewer pipes PVC and HDPE for outdoor sewage: types, characteristics, advantages and disadvantages

When installing the drainage system, PVC sewer pipes are used for external sewage, as well as HDPE pipes. In many respects similar in their technical and technological characteristics, these products still have a number of significant differences that affect the ease of installation and subsequent operation of the sewer system.

We will talk about the properties of polymer materials for the production of pipes. We will show you how to choose the type of pipe so that the installation is less time-consuming and faster. Based on our advice, you can easily select products for the installation of external sewer networks.

The content of the article:

General requirements for pipes for outdoor sewage

Since the construction of an external sewage system requires a lot of effort, and its service life directly depends on the stability of the network elements to adverse conditions, an appropriate margin of safety is laid in the production of sewer pipes: greater resistance to temperature fluctuations, to soil pressure.

What parameters characterize PVC and HDPE sewer pipes used for outdoor sewage:

- Material. For external sewage pipes made of durable materials are used, which are able to withstand not only the aggressive environment of wastewater, but also a temperature drop, mechanical loads. The properties of these materials are the most important criterion when choosing the type of pipe.

- Wall thickness. Given the pressure that is a ball of soil, as well as the location of some types of soil to heaving in the winter, the pipe wall thickness for the external line should be 1.5 times furtherthan for the inside.

- Design. The strength of the pipe, resistance to deformation, and the method of installation of the system depend on this parameter.

- Sizes. The diameter of the pipes, their lengths are calculated at the design stage of the sewer system

- Colour. Pipes for outdoor use are painted orange. This contributes to their easier detection during the repair of the drainage system or other earthworks and helps to avoid damage.

The choice of pipes for the external sewer network is a responsible task, because the installation work is expensive and time-consuming and the longer the pipes last, the better.

When choosing and buying sewer pipes it is better not to save on their quality, to study the characteristics of products and operating parameters.

The use of polymer pipes

Polymer pipes include products made of synthetic compounds made of PVC and HDPE. All polymer pipes have similar properties and characteristics that appeal to both builders and consumers.

Significant advantages are lightness, durability, low cost. These and many other qualities have made polymer pipes popular in the construction of waste water networks.

The use of polymer pipes when installing an external pipeline is especially important.

What makes polymers so convenient material:

- Ease. Laying to a depth of 1.5 m, the large length and diameter of the pipes for laying the external sewage system means a rather large complexity of installation work. The use of polymer elements greatly simplifies installation, reduces the cost of installation and eliminates the use of special equipment and tools.

- Strength. The material withstands heavy loads, suitable for laying pipes in the ground. It is resistant to mechanical damage, has great compressive strength.

- Surface smoothness. An important property for pipes that discharge drains is a smooth inner surface on which deposits do not linger.

- Corrosion resistant properties. Polymeric materials do not interact with moisture at all, as well as with most chemicals.

In addition, plastic pipes normally tolerate temperature surges, seasonal weather changes. But in the open air it is not worth laying PVC pipelines - they are destructively affected by ultraviolet rays. On the street, pipes made of polymeric materials can last for a long time only in a protective casing.

PVC pipes for outdoor sewer

PVC sewer pipes are made from polyvinyl chloride - an affordable and popular plastic that is widely used for the production of many plastic products.

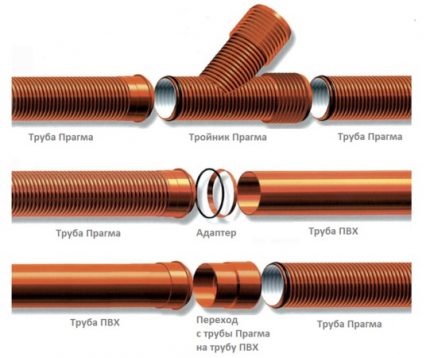

Products can be single-layer (monolithic) and three-layer, in which the intermediate layer is made of porous PVC-U, and the other two from the primary PVC-U. In laying external sewer branches, they are popular corrugated pvc pipewell resisting soil pressure.

PVC pipes are used mainly for the construction and repair of pressureless sewers with a system pressure of not more than 0.16 MPa, for the removal of storm drains. They are used for the disposal of aggressive wastewater, liquid and gaseous media with chemical resistance in the range of 2-12 pH, temperature from 0 to +60 ° С.

At installation of the external sewerage Pvc pipe dipped to a depth below the freezing of the soil or use heat-insulating materials to protect against freezing.

Open sections of the system protect from sunlight.Long-term exposure to ultraviolet radiation on pipes made of polyvinyl chloride leads to photodestruction - loss of elasticity, strength.

According to the ring stiffness class, products are marked as:

- SN2 - 2 kN / m2 - the depth of laying such pipes underground to 1 m;

- SN4 - 4 kN / m2 - laying depth up to 6 m;

- SN8 - 8 kN / m2 - laying depth up to 8 m.

The thickness of the walls distinguish between light, medium, heavy type of pipes with indicators from 2.2 to 12.3 mm. For external sewage, PVC pipes with wall thicknesses from 2.7 mm are used, their diameter varies from 110 to 630 mm.

The standard dimensions of sewer pipes are sections 0.5 m, 1 m, 2 m, 3 m, 6 m long, sometimes up to 12 m - the dimensions are indicated by the manufacturer without a bell.

The most popular sizes of PVC pipes are products with a diameter of 110-200 mm and a stiffness class of SN2. In terms of price and performance, they are an ideal option for construction autonomous sewer on a country site.

HDPE pipe for installation of an external sewer network>

HDPE pipes are made of low-pressure polyethylene; the continuous extrusion method is used. The material does not interact with acids, alkalis, organic acids and water - the higher its density, the more resistant it is to organic solvents.

The smooth inner surface of the pipes does not impede the free movement of effluents with mechanical particles and is not subject to silty, calcareous deposits.

The operating temperature range of a polyethylene pipe for sewage is from -20 to 60. HDPE pipes are used for the installation of pressure and non-pressure sewage, drainage and storm systems.

For a short time, the polymer pipeline can withstand temperatures up to 100. Pipes are mounted underground or protected by insulating materials from sunlight - the material is sensitive to UV radiation and decays quickly enough under its influence.

Double Layer Corrugated Pipe

In the construction and repair of communal and industrial facilities, it is corrugated pipes made of polymers that are widely used. The first such options were made of PVC, now they use polyethylene as a material that better resists the effects of aggressive wastewater and organic compounds.

Since pipes with a diameter of more than 315 mm with stiffness classes SN16, SN8 are more in demand for large-scale construction, it is corrugated products that are the most acceptable option when evaluating the price-strength ratio.

The winning characteristics of corrugated pipes are achieved by using a special manufacturing method, in which both walls of the pipe are produced at the same time, are interconnected and form a monolithic structure.

Between the outer wavy surface and the inner smooth cavity are formed, contributing to the relief of the product. Corrugated outer wall provides sufficient annular rigidity, provides resistance to deformation.

The inner layer of the pipe has a perfectly smooth surface and does not contribute to the formation of deposits and the accumulation of sludge, mechanical particles.

The polyethylene sewer pipe is designed to operate at a temperature not exceeding + 40 ° C and a short-term increase to +60 ° C. For external networks in which the temperature of the drained liquid does not rise above + 35 ° C, this is quite enough.

Comparison of PVC and HDPE pipes for outdoor sewers

To summarize, the advantages of PVC pipes include:

- wear resistance;

- light weight;

- widespread use;

- anticorrosive properties;

- ease of installation sewer system;

- low cost.

Disadvantages of PVC pipes:

- do not tolerate subzero temperatures;

- sensitive to shock at low temperatures;

- Do not transport substances with temperatures above 45 ° C through the pipeline.

PVC pipes are used both in laying the external lines of the system and in organizing the inside sewer of a private house.

Pipes PND differ in the following advantages:

- material strength;

- not susceptible to corrosion;

- wear resistance, durability;

The substantiated technical and technological advantages include ease and versatility of use. Very attracted by a larger range of operating temperatures.

The disadvantages of polyethylene pipes include:

- high cost compared to other types of plastic pipes;

- more laborious process of mounting system elements.

The main parameters that pay attention when buying pipes for sewage are the material of manufacture, design, dimensions.

In addition to pipes for the installation of the outer part of the autonomous sewer system, plastic wellsused to organize rotary, collector and viewing points. The guidelines of their choice will be introduced by our recommended article.

Conclusions and useful video on the topic

Types of pipes for external and internal sewerage:

Installation of PVC pipes for outdoor sewage:

The assortment of pipes used for the construction of an external sewage system is quite wide, but PVC and HDPE sewage pipes are most in demand due to their quality characteristics and cost.

It is impossible to unequivocally affirm and advise which type of pipe to choose when installing a sewer system - from polyvinyl chloride or polyethylene, since when choosing it is necessary to take into account the conditions in which the system will be used, the financial capabilities of the owner.

Do you want to talk about what type of pipes you chose to organize an external sewage system in a suburban area? Share the arguments based on which you chose your option. Please leave comments in the block below, ask questions, post a photo on the topic of the article.

Sewer polymer hatches: types and characteristics + features of use

Sewer polymer hatches: types and characteristics + features of use  Polymer-sand wells: device, advantages and disadvantages, installation rules

Polymer-sand wells: device, advantages and disadvantages, installation rules  How to lay sewer pipes in a private house: schemes and rules for laying + installation steps

How to lay sewer pipes in a private house: schemes and rules for laying + installation steps  Pipes for domestic sewage in the house: a comparative overview of modern types of pipes

Pipes for domestic sewage in the house: a comparative overview of modern types of pipes  How to clean sewer pipes in a private house: varieties of blockages and methods of cleaning

How to clean sewer pipes in a private house: varieties of blockages and methods of cleaning  Insulation for sewer pipes: types, selection rules and overview of laying technology

Insulation for sewer pipes: types, selection rules and overview of laying technology  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements