Polymer-sand wells: device, advantages and disadvantages, installation rules

In the composition of drainage systems, water supply, external sewage and stormwater there are various well structures. Previously, they were equipped with wood, then made of brick and reinforced concrete. But now more and more polymer and composite materials have been used.

One of these options is a polymer sand well made of prefabricated elements. Why is it so good, can you assemble it with your own hands? We will analyze these issues in detail in our article.

And also consider the constituent elements of a polymer sand well, the features of its use, the main pros and cons.

The content of the article:

Device and specifications

Initially, the walls of well shafts were reinforced with log cabins made of wood of waterproof species. Then they began to do this with the help of reinforced concrete rings.

But in the last decade they have been replaced by composite building materials, which are not inferior to concrete in strength characteristics, and significantly surpass it in ease of installation.

Elements of polymer-sand well are made from:

- plastic (recyclable materials in the form of waste from various polymer products);

- fine sand with a moisture content of 0.1 to 10%;

- multicolored pigments based on iron oxide.

According to the manufacturing technology, the sand filler must be dry and uniform. Quality products are obtained only from alluvial sand. Then, voids do not form inside it, leading to a decrease in the strength and water resistance of the well parts.

Some unscrupulous manufacturers use a sifted career counterpart instead of a preliminary flush instead.As a result, after a couple of months, caverns and voids form in the polymer-sandy product, and simply holes - lumps of clay rocks fall out of the plastic.

With high humidity of the feedstock, not only increases the cost of evaporation of moisture, but also decreases the strength with moisture resistance of the material. It is no longer so durable, frost-resistant and resistant to water.

However, when buying, by eye, to determine poor-quality products is almost impossible. Here you have to rely entirely on the honesty of the manufacturer.

Dyes are added to the product at the stage of preparation of the mixture and baked with it in the process of hot pressing. They become part of the overall molecular structure of the material.

Therefore, even hatches made of polymer sand, which are constantly in the sun, do not fade and do not require tinting.

Characteristics of polymer-sand products

The sand filler used in the manufacture of the mixture accounts for about 75–80% of the total mass. He is responsible for the rigidity of the product. The rest is a binder polymer and a dye. Polymeric components bind sand into a durable, almost waterproof monolith.

As a result of hot pressing, a product is quite light, durable, strong and resistant to aggressive environments.

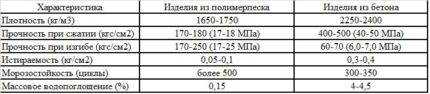

Polymer sand products are more durable and water resistant than concrete competitors. They calmly tolerate temperatures up to minus 70 Celsius. And withstand up to 500 freeze / thaw cycles.

In this case, the polymer-sand composite is resistant to chemicals. He is not afraid of the aggressive environment of sewage. And when washing the well, you can use any detergents, both domestic and industrial.

Operational Features

Structurally, the well is a vertically buried hydraulic structure. During operation, it is exposed to groundwater and wastewater, as well as to temperature changes during the winter freezing of the soil and subsequent thawing.

The material of its manufacture must have increased resistance to these factors, otherwise the tightness of the tank will be called into question.

Polymer-sand wells differ in the diameter of the inner rings and the hatch. These elements are quite durable, but if gaps appear, it will be difficult to repair them. The best option in this case is a complete replacement of the leaky part.

On the one hand, polymer-sand well structures are cheap and easy to assemble, while on the other hand, their individual parts are not subject to repair. If holes appear in the walls of the ring, you will have to change it. And for this it will be necessary to dig a well to the level of damage and re-shift its elements.

Manufacturers promise up to half a century of operation of products from polymer sand and perfect tightness of the joints of the rings. Provides tightness due to the groove along the edge of all elements of the well, which do not allow the rings to disperse when the soil moves.

Another weighty plus of the tongue-and-groove lock at the ends of the rings is that when assembling the well spontaneously verticality is observed.

A negative nuance is the flexibility of the polymer base to mechanical influences. If you use hard scraper when cleaning the well and apply excessive zeal in doing so, you can damage the polymer walls, as a result, reduce the water-repellent qualities of the underground structure.

Where are polymer sand tanks used?

Well structures made of composites can be found on roads, industrial sites and territories of private estates.

They apply:

- When organizing storm sewers for drainage well devices and manhole for drainage.

- As septic tanks, sewer drains.

- When arranging wells with industrial water.

- As tight walls during construction well box.

Sealed structures are assembled from separate polymer-sand rings mainly for the accumulation and discharge of effluents.

They perfectly retain sewage sewage inside, do not react to the aggressiveness of such an environment, perfectly prevent the penetration of liquids outside the sewer system.

The device of a typical well made of polymer sand composite

Well polymer-sand construction consists of several modules:

- Bottom (round base detail).

- Rings in the required number of pieces.

- Tapering up neck.

- Luke.

Most often on sale there are parts with a diameter of 850, 1000, 1100 mm. But everything here depends on the manufacturer and the purpose of the design. There are no strict state standards in this matter, all products are manufactured in accordance with technical specifications.

From polymer sand, you can make a well of almost any depth. It is enough to collect the required number of rings and connect them together. It is only necessary to correctly select the wall thickness so that they withstand the weight of the structure from above.

The base has a thickness of 4.5 - 5 cm, and the ring is available in a height of 20 cm. The hatch and neck in the form of a truncated cone come in different sizes. On all parts there is a protrusion ("comb") and a recess ("groove"), which allows you to quickly and tightly connect the parts in a monolithic structure.

Polymer-sand hatches differ in the type of load on:

- Lungs (withstand up to 3 tons). Are applied at the device of viewing and drinking wells on house adjoining sites of a private sector, and also in a zone of green spaces.

- Medium (able to withstand up to 5-6 tons). They are used in parks, on sidewalks and in small car parks for cars.

- Heavy (withstand up to 12 tons). Designed for roads and adjoining territories in cities.

- Super heavy (not destroyed even at loads of 25 tons).

The price of different manufacturers and in different regions varies in a fairly wide range. But on average, a ready-made set of a polymer-sand well three meters high will cost 25,000–28,000 rubles.

Composite hatches are without a locking mechanism, with threaded fittings (secret bolt) or a flag or spacer latch.

For private households, the first option is suitable, but in a park or on the sidewalk it is better to close the well with a polymer-sand hatch with reliable lock, otherwise it can simply be carried away.

Handing over a plastic product on metal will not work, but our compatriots are able to adapt any thing in the household. It’s better to be safe.

We examined the features of polymer sewer manholes in more detail. in this article.

Advantages and disadvantages of such a well

Among the advantages of polymer sand wells it is worth mentioning:

- Light weight of individual parts and the entire structure.

- Ease of installation work.

- The ability to make structures of any depth.

- Resistance of the polymer composite to moisture, frost and wastewater.

- Easy to connect sewer pipe in from home.

- Guaranteed service life of 50 years.

- Environmental safety of the material.

- Benefit at a price among analogues (by the total cost of consumables and installation).

Composite materials made of plastic and sand are not afraid of salts, acids and alkalis contained in sewage and soil. It calmly withstands the continuous exposure to water, and the accumulation of soil in the winter, and sudden frosts.

Some manufacturers claim a hundred years of operation without major repairs. But who checked this? Too little time has passed since their appearance on sale.

A polymer sand ring weighs about 50-60 kg, and its diameter is a little more than a meter. It can be transported in the back of the Gazelle, and even one person can handle loading / unloading.

When installing a polymer sand well, it will not be necessary to involve lifting equipment. To install the elements in the dug hole, just a pair of hands and ropes.

What can not be said about the reinforced concrete analogue. We recommend that you familiarize yourself with the installation features in more detail. reinforced concrete ring septic tank.

The only significant drawback of the well structure from the composite under consideration is the inability of the material to withstand heavy loads with the wrong choice of cover and ring thickness. If you put a truck on a light hatch, the first one will inevitably crack.

The same situation with rings. If products with thin walls are laid at the very bottom, and the well itself is made very deep, then it will not last long. The bottom row will simply fall under the mass above. No tricks in the form of props and reinforcements will help here.

Standard mounting technology

Work can be performed both in summer and in winter. Difficulties with the assembly of parts should be minimal. Problems can only be caused by the digging of frozen ground. The main thing is that the sealant used allows operation at the existing street air temperature.

Installation is carried out in five stages:

- Unloading composite parts.

- Digging a pit.

- Assembling the “constructor” from polymer sand segments.

- Piping connection.

- Backfill soil.

Everything is simple, you can cope with the work yourself without involving hired workers. It is important to correctly calculate the required number of rings or carefully follow the project.

Stage # 1 - Parts Preparation and Earthwork

The heaviest element in the well weighs no more than 60 kg. To unload the machine will be enough efforts of a couple of people. At the same time, the weight of the entire structure will not exceed a couple of tons; one “Gazelle” is enough for its transportation from the store.

Despite the high strength characteristics during transportation and storage, rings should be shifted by boards. And the bottom is better to put on a pallet or platform made of wood.

It will be necessary to dig a hole under the polymer-sand well 120-130 cm wide. The outer diameter of the rings does not exceed 110 cm. Ten centimeters on the sides is enough to lower the parts into the dug shaft.

If the well is made without a bottom, then a variant with a gradual excavation of the earth under the lower ring is possible. But with such a digging, the pit will have to be dug wider, otherwise working with a shovel will be inconvenient. Is it worth it to do the extra work, taking out one and a half to two times more soil - it's up to the digger to decide.

Stage # 2 - laying sections and insert pipes

The assembly of well rings can be performed both in the pit itself, and next to the subsequent descent downward at once of all or part of the structure. In any case, you can do with the forces of two people.But when lowering the already collected well into the pit, you will need a tripod with a winch or a crane.

The bottom or starter ring is laid on a sand pad 15–20 cm thick, pre-poured and rammed at the bottom of the pit.

Next, the groove in them is filled with sealant or bitumen mastic and the next part is inserted into it with a comb. So one by one all the other rings are stacked, and the neck is installed on top.

Polymer sand is quite easy to handle. Holes in it under the pipeline entries can be made without the use of powerful tools. Enough ordinary drill with a conventional crown for concrete or ceramics. Plus, it is not necessary to grind the edges after such drilling or otherwise process.

To seal the junction of the pipe and the wall, it will be enough to insert a rubber cuff into the hole.

Stage # 3 - connecting pipes and checking for leaks

After installing the polymer-sand well in its place in the pit, sewer pipes are connected. For more information on installing external sewage pipes, go to this link.

Then, the joints are checked for tightness, for which water is poured into the resulting container. If the leaks are not noticeable, it remains only to fill up the gap between the walls of the pit and the well structure.

The material of the polymer sand well does not require insulation. But in cold regions, a heat insulator in the form of foam is still recommended to be laid, otherwise the liquid inside will freeze. Here it is necessary to be guided by the design of a sewer or storm system, of which the assembly is part.

If the polymer sand type of well does not suit you, we suggest that you read the instructions for installation of sewer wells from other materials.

Conclusions and useful video on the topic

Answers to frequently asked questions about such wells:

Nuances of installing a polymer-sand well:

Advantages and disadvantages of polymer composite products:

A prefabricated well, sections of which are made of a polymer-sand composite, has many advantages over its counterparts from other materials. It is resistant to various negative factors, durable and fairly cheap.

This is an excellent option for forming inspection shafts when laying cable lines and septic tank chambers. But when buying polymer products for the device of a drinking well, you should look at the certificates. Not all products are applicable in this case.

Have you made a well of polymer sand rings at your cottage with your own hands? Tell me, did you need assistants in the assembly and installation, or did you manage all the work alone?

Or maybe you are just planning the construction of this type of well and you still have questions after reading the article? Define them in the comment box below.

Viewing wells for drainage: types, arrangement and installation features

Viewing wells for drainage: types, arrangement and installation features  Plastic sewer wells: varieties + installation features

Plastic sewer wells: varieties + installation features  Plastic wells for drainage: device, types, classification, installation instructions

Plastic wells for drainage: device, types, classification, installation instructions  Sewer pipes PVC and HDPE for outdoor sewage: types, characteristics, advantages and disadvantages

Sewer pipes PVC and HDPE for outdoor sewage: types, characteristics, advantages and disadvantages  Sewer wells: full classification and examples of arrangement

Sewer wells: full classification and examples of arrangement  How to lay sewer pipes in a private house: schemes and rules for laying + installation steps

How to lay sewer pipes in a private house: schemes and rules for laying + installation steps  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

When you read about this, you think: where were you twenty years ago? I still remember how we dug and laid a well with brick and stone. It took us a couple of weeks. Now this period can be reduced to a few days, for a maximum of a week. It seems to me that they have now created such conditions - “I do not want a system”, I even began to envy. Still wondering how much it all costs?

Good afternoon, Alexey. The cost is not indicated on the site due to the difference by region. Reference point:

1. Luke - 1500 rubles;

2. Neckline - 2500 rubles;

3. Ring - 1500 rubles;

4. The bottom - 1500 rubles.

To voice the cost of work will be incorrect. Remuneration in Moscow and, for example, in the same Krasnodar is several times different.

Good afternoon! Will sanding concrete be required after installing a caisson made of polymer sand material so as not to “stick out”?

Good afternoon, Ivan. If you pay attention, there are stiffening ribs along the outer circumference of the ring. Their purpose, among other things, is to keep the collected well in place. Most often, backfilling is done with sand or soil with a layer-by-layer tamping. In the case of unstable soils in the area, I would recommend backfilling with sand concrete.

Do not forget about the weak point of the polymer sand well, this is the fragility of the material. The market offers ready-made options for 1.5 m., 2 m., 3 m., And the longer the length, the thicker the walls of the components of the well.

Hello! Tell me, please, how is it better to insulate the caisson from such a well for a drinking well in the Siberian region, the landmark is the city of Krasnoyarsk? And is it necessary to make a concrete base for anchoring this design?

To be honest, for the Siberian region it is better to approach the construction of a caisson thoroughly. I recommend making concrete rings to a depth of more than 2.5 meters, then additional insulation will not be needed.

I attach images where it is clear that there is frost inside the caisson in the area of contact with the soil line, and below it is no longer there. In the caisson itself, the temperature is positive, the water in the bottle did not freeze.

If you decide to mount a caisson made of polymer, then with a small depth it is necessary to insulate, in this regard, penoplex is best suited. A concrete base is required. With a caisson depth of more than 2.5 meters, additional insulation will not be needed.