Corrugated pipes for external sewage: types, rules and standards of application

The invention of corrugated pipes greatly facilitated the fate of the builders of external communications. They are practical and convenient in transportation, styling, connection.

High strength and rigidity of corrugated systems is excellently combined with light weight, resistance to water and aggressive environments. But for a competent purchase, you need to get acquainted with the types and advantages of the corrugation. Do you agree?

If you want to know how to choose the right corrugated pipes for outdoor sewage, we will find answers to all your questions. Using the information provided will help in the assembly and construction of a reliable network.

The article describes the technological subtleties of the construction of sewer communications from corrugated pipes, provides valuable recommendations on the installation and operation of the finished system. The leading foreign and domestic manufacturers of a popular type of product are listed.

The content of the article:

- Features of corrugated pipes

- Varieties of applications

- Pipe classification by material

- Corrugated pipes: advantages and disadvantages

- PVC and PNT product standards

- Sewer Pipeline Service

- Corrugated Pipe Connection Methods

- Domestic and foreign manufacturing companies

- Conclusions and useful video on the topic

Features of corrugated pipes

Corrugated pipes made from modern types of polymers have a peculiar appearance due to the elastic folded surface.

Such products can have a single or double layer structure, while the second option, combining the corrugated outer shell with a smooth inner surface, is especially common. In this case, the corrugated structure reliably protects the core of the pipe from mechanical stress, in particular from soil pressure.

Typically, the diameter of a two-layer plastic pipe varies between 110-1200 mm, while the ring stiffness is 4 to 16 KN per square meter. m

Like smooth outdoor sewage products, corrugated elements are usually orange, red or brown, however, some manufacturers produce pipes of this type of other tones, for example, black.

Differences of ribbed products from smooth ones

Corrugated pipes surpass smooth analogues in a number of indicators:

- they are many times more reliable, stronger, more resistant to impacts;

- they have increased flexibility and elasticity, which makes their laying easier, including in difficult conditions, for example, on relief changes;

- for the installation of corrugated products, fittings and other connecting elements are practically not required, without which it is impossible to assemble the system from smooth pipes;

- corrugations have the ability to regulate the degree of rigidity by thickening some rings - this function may be needed when laying underground sewers;

- in the event of a leak or other flaws, the corrugated pipe is easier to repair than a smooth one.

It is easy to make sure that the consumer qualities of corrugated elements significantly exceed the performance of traditional counterparts.

The use of various types of corrugated pipes

Products with a folded structure are widely used for various purposes:

- assembly of drainage schemes;

- non-pressure rainwater drainage devices;

- installation of systems designed for the disposal of industrial effluents;

- non-pressure wiring underground drainage schemes - household, general alloy;

- constructions intended for agriculture.

Special varieties of plastic corrugated pipes, which have increased rates of ring stiffness and frost resistance, are suitable for arranging passages under highly loaded highways.

Varieties of applications

Given the areas of use of pipes having a folded structure, the following categories can be distinguished.

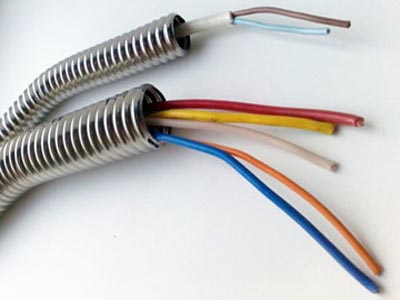

To protect wires and cables use electrical corrugations. These products have average elasticity and resistance to mechanical damage.

Single-layer corrugated pipes are lighter with more flexibility. Such large-diameter elements are often used to protect the gas pipeline, and compact products for cable laying.

Double-layer corrugated hoses are characterized by good rigidity and durability, which allows them to withstand heavy loads. Usually they are used for mounting cables in difficult conditions, for example, deep underground.

Corrugated pipes consisting of two layers. Such products have excellent strength / resistance to aggressive substances, which allows them to be used for laying sewers.

Pipe classification by material

Most often, polymers such as polyvinyl chloride (PVC) and polyethylene modifications (PTN, PND) are used to produce corrugated pipes of various modifications. Below we will consider in detail both types of materials:

Option # 1: PVC Products

One of the most common types of plastics - polyvinyl chloride - has the following qualities:

- high coefficient of wear resistance;

- inertness to aggressive environments, including alkalis, acids, mineral oils;

- frost resistance: even with complete freezing, cracks do not appear on the material;

- incombustibility - at + 120 ° C, PVC decomposes with the release of carbon monoxide.

The disadvantages of such a material include sensitivity to high temperatures: polyvinyl chloride products begin to deform even at + 60 ° C.

PVC pipes are considered universal: they can be used for laying industrial and private sewer systems. The high strength of such products, as well as resistance to loads, allows them to be used for underground installation in the most stressful places, for example, under busy roads with a large traffic flow.

Two types of elements used for laying communications can be distinguished, namely:

- sewer corrugated pipes;

- probes used as protective structures for cable lines.

Depending on strength polyvinyl chloride pipes can be divided into the following categories.

Lungs. They have low resistance to stress. Mainly used for mounting external systems.

Heavy. The average mechanical strength allows you to lay similar structures underground at a depth of 15 m.

Super heavy. They have the highest stiffness indicators, so they are suitable for mounting schemes in areas experiencing increased mechanical stress: heavy soils and areas located under the roadway.

To optimally solve a specific problem, it is also important to consider the diameter of the pipe and other qualities.

Option # 2: polyethylene products

For the production of corrugated products, high-quality brands of polyethylene PE80, PE63, as well as polyethylene obtained at low pressure (PND) are used.

Used varieties of plastic have the following properties:

- absolute resistance to alkalis and acids;

- excellent frost resistance (it should be noted that pipes made of this material are stretched during freezing;

- good strength, durability;

- increased elasticity;

- environmental friendliness, because the polymer can be recycled.

The only drawback of polyethylene is the lack of resistance to elevated temperatures. However, there are some modifications of this polymer that can withstand the transportation of warm and even hot waste up to + 80 ° C.

Corrugated pipes made of polyethylene have a two-layer construction.Such products are used for the installation of external sewers, and due to the high rate of ring stiffness, they can be laid at a depth of up to 20 m.

The scope of polyethylene corrugated elements is very extensive, but most often they are used for laying sewer lines and organization of drainage systems. Products for soil drainage are made of perforated materials, so they have an excellent balance of light weight and high strength.

Easily mounted circuits are extremely efficient in operation and can last for many years.

Another advantage of HDPE pipes is increased elasticity: they can be mounted without fittings, which greatly simplifies the process and reduces the cost of installation.

Comparison, specifics of application and marking of PVC and HDPE pipes for external sewage are described in this article.

Corrugated pipes: advantages and disadvantages

Regardless of the material from which corrugated products are made, they always have a number of important advantages:

- A light weightdue to which the warehousing, transportation, laying of such elements is facilitated.

- Easy installation, for the implementation of which additional devices, equipment, sophisticated equipment are not required.

- Low cost all types of products.

- Long life. A properly mounted corrugated pipe system will last at least 50 years and more.

- Smooth inner wallswhich create an ideal surface that prevents the formation of congestion.

- Excellent performance: High coefficients of ring stiffness and strength allow the use of corrugated pipes for any purpose.

The disadvantages of such products include sensitivity to high temperatures. It is better not to use polymer corrugations for transporting hot waste or to use special modifications for this, for example, from cross-linked polyethylene.

Plastic constructions are often excessively susceptible to ultraviolet light, so it is advisable to organize their storage under a canopy to avoid direct sunlight.

PVC and PNT product standards

There is a normative document relating to PVC sewer pipes, namely GOST 51613 "Pressure PVC pipes", which lists the standards for products with a diameter of 10 to 315 mm, including those including bell-shaped elements with rubber seals.

At the same time, other versions of pipes made of this material have long been used in construction, including corrugated structures for external sewage. Similar products with a diameter of up to 630 mm are manufactured according to TU (TU 2247-001-97341529-2008 and others).

There is also GOST 14254-96, which regulates the degree of protection for corrugated PVC pipes for sewage.

In addition, different countries may have their own standards for polymer corrugations, such as EN 13476-3, adopted in the EU countries.

Sewer Pipeline Service

Thanks to corrosion resistance, resistance to frost and mechanical stress, corrugated systems have improved performance, which can significantly reduce the repair work. However, periodically it is advisable to take measures to prevent the formation of blockages.

For this purpose, two methods of cleaning pipes are used:

- Dry cleaningbased on the use of active drugs that are introduced into the sewage system.

- Hydrodynamic cleaning, which is carried out using a special tool that allows you to load steam or water under high pressure into the pipeline.

The first option is usually used as a preventive measure, while the second, with a stronger effect, can effectively eliminate already existing congestion or deposits of mineral substances.

Corrugated Pipe Connection Methods

When installing the pipeline, it is important to follow the following instructions.

All work is preferably carried out in spring or summer at an air temperature above 15 ° C. Before starting laying, it is important to carefully inspect the products to make sure there are no visual defects, as well as compliance with the dimensions that are provided for projects.

Pipes are laid out along the side of the dug trench, so that their bells are oriented on the opposite side of the slope.

Before starting installation, thoroughly clean the socket and the smooth end of the element, removing dust and dirt.

With a bell-shaped connection of structures, it is necessary to use rubber seals. To do this, the ring is inserted into the groove on the second turn of the corrugation, while it should be observed that the profile of the sealant is oriented in the opposite direction from the direction of insertion of the element into the socket.

In some cases, instead of a socket connection, butt welding is used, which is carried out in accordance with GOST 16310-80. The process is similar to the connection of conventional polymer pipes using welding machines the same type.

To do this, heat up the end of the pipe until the polymer begins to melt. Then it is enough to connect the elements by applying a certain pressure. After complete cooling of the structure, a monolithic seam will be visible on the plastic surface.

To get a good result, it is important when choosing the welding mode to take into account the diameter of the parts to be welded, as well as the wall thickness of the components.

For dissimilar compounds, for example, plastic corrugated pipes with products made of cast iron, asbestos cement, steel, reinforced concrete and other types of material, special devices are usually used - flanges or couplings.

More complex options, ensuring the tightness of the design of several elements, is the use of a coupling with a sealing ring, which is installed in the groove of the corrugated pipe.

It is important to fulfill the following condition:

- if the diameter of the product is 250-1200 mm, it is inserted into the first groove of the corrugation;

- if the channel cross section is 125-200 mm, then in the second.

When installing the ring, it is important to ensure that its profile is directed in the opposite direction from the end of the pipe.

Domestic and foreign manufacturing companies

Corrugated products are produced by many enterprises. We will name only a few of them as an example.

Popular Russian companies

Russian manufacturers produce an extensive assortment of corrugated products for piping. At the disposal of customers pipes of different diameters and connecting fittings to them.

POLITEK

A domestic company, founded in 1999, has production facilities in Tula and in Odintsovo (Moscow region), where modern imported equipment is installed.

In the production of products, innovative technologies are used to produce products of European quality.Much attention is paid to the quality control system: each batch is mandatory checked in factory laboratories.

The assortment of the company includes a variety of polymer products, including two-layer corrugated pipes of various sizes, designed for laying an external sewer and cable.

POLYPLASTIC

The largest multinational company, headquartered in Moscow, and units in several CIS countries (Russia, Kazakhstan, Belarus).

The company, whose activities began in 1991, offers a huge assortment of pipes made from different types of polymers. Products in the catalog differ not only in size, but also in consumer qualities, as well as in the internal structure, which allows customers to choose the best option for a particular purpose.

For outdoor sewage, the company offers a line Corsis, including plastic products with a diameter of 200 to 3000 mm. The choice of options is quite wide: two-layer corrugated pipes of different sizes, multilayer reinforced options, spiral-wound elements.

NASAHORN

One of the most respected domestic companies operating in the market of our country since 2004. The company produces various types of plastic pipes for internal / external sewerage, including corrugated products (single-layer, double-layer).

In their manufacture, advanced technologies and high-quality raw materials are used, which allows the manufacturer to give a 50-year warranty on all types of products.

Pipes NASAHORN can be purchased in many cities of Russia, as well as in several CIS countries. The company is constantly improving its range, offering consumers more and more new options for polymer products.

Well-known foreign companies

The Russian market presents products from foreign companies. You can buy inexpensive products and products from the highest price segment.

OSTENDORF

German concern Ostendorf Kunststoffe was created in 1973 for the production of polypropylene pipes and fittings, rapidly breaking into the markets of Europe.

The company quickly took a leading position, which it still does not lose, remaining the leading supplier of polymer products in Germany, as well as supplying products to many countries of the world.

In 2011, the company opened a factory Ostendorf rusoperating in the city of Yegoryevsk, Moscow Region. The entire range of products is manufactured here on the latest German equipment from imported raw materials with strict quality control carried out by specialists from Germany.

The company produces pipes and accessories for the installation of an external sewage system, which are made from a particularly hard variety of polyvinyl chloride. Multilayer products are of the highest quality, which allows you to use them under any conditions

Wavin

The Dutch company, founded in 1955, was one of the first in Europe to begin production of sewer and plumbing polymer pipes. Currently, its products are supplied to many European countries.

For the external sewage system, the company's specialists have developed an extremely reliable pipe system. X-Stream having a double wall with high ring stiffness (SN8). Products have different diameters (100-800 mm) and fully comply with the standards adopted in Europe.

In addition to corrugated pipes, the range also includes various options for fittings having a special bell shape, which allows installation without any bonding.

FRANKISCHE

German family company, founded more than a century ago, in 1906. The assortment includes products made of polymers and metal, which are necessary in various fields of the national economy: in civil and industrial construction, for laying motorways, etc.

The company's products are well known both in Germany and in several European countries.

Corrugated products intended for the installation of waste or storm water drainage systems occupy an important place in the catalog. Options with two-layer walls are offered, with various indicators of ring stiffness (SN16, SN8).

The proposed products provide complete tightness, they are easy to assemble, reliable, easy to operate.

Conclusions and useful video on the topic

In the video below, you can clearly see the process of connecting two-layer corrugated pipes at the facility:

Corrugated pipes combine many advantages: ease of installation, resistance to aggressive materials, mechanical stress, low temperatures. With careful selection of products and proper installation, the sewer systems created from these elements will serve for a long time and reliably.

Do you have experience using corrugated pipes for arranging external sewers? Or have questions about the topic? Please share your opinion and leave comments - the contact block is located below.

Cast iron pipes for outdoor sewage: types, features of application and installation

Cast iron pipes for outdoor sewage: types, features of application and installation  PVC pipes for outdoor sewage: types, sizes, advantages and disadvantages

PVC pipes for outdoor sewage: types, sizes, advantages and disadvantages  Sewer pipes for outdoor sewers: types and overview of the best brands

Sewer pipes for outdoor sewers: types and overview of the best brands  Sewer cleaning cable: types of tools and how to use them correctly

Sewer cleaning cable: types of tools and how to use them correctly  Concrete sewer rings: types, labeling, manufacturing methods + manufacturers overview

Concrete sewer rings: types, labeling, manufacturing methods + manufacturers overview  Sewerage ventilation in a private house: schemes and design rules

Sewerage ventilation in a private house: schemes and design rules  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

When the question arose of which pipes to use for sewage in a new private house, we dug up the entire Internet. We consulted with a specialist contractor and agreed that it is better to use a corrugated pipe designed for these purposes.Bribed by the fact that they are lightweight, durable and fairly cheap, easy to install. Due to their smoothness, they prevent the formation of congestion.

Corrugated pipes, of course, have more advantages over ordinary smooth ones: installation is much easier and in operation this material is more reliable, better resists to negative environmental influences. He worked with the German Frankisch (FRÄNKISCHE), the quality is high, but they do not have a different way. However, our Polyplastic is no worse, and at a cost even more profitable. Polymers serve for a long time, are undemanding in care.