How to reduce the power of a gas boiler: the best options to reduce gas consumption by the boiler

The cost of energy is growing with enviable regularity, so whether you want it or not, you have to think about how to reduce the power of a gas boiler in order to save. Indeed, overpaying for “blue” fuel is impractical, unprofitable, and simply unreasonable. Do you agree?

Moreover, in many cases, saving gas, and with them, money is not difficult. And how to do this, read further in our publication.

The content of the article:

The simplest ways to reduce power

The simplest and most effective, as well as operational methods that help save gas and reduce power include adjusting the boiler settings. Using them you can reduce consumption by a quarter.

These methods of reducing power include:

- adjust settings in manual mode;

- power adjustment in auto mode.

Both options can be used individually or in combination. That will help increase the energy efficiency of any heater to the optimum value.

Method # 1 - manual adjustment

This is the most inexpensive and fastest method of making adjustments to the operation mode of your gas boiler. Since the whole procedure resembles a decrease in the sound volume of the TV.

After all, all you need to do is perform 2 simple steps:

- Enter boiler service menu (not to be confused with regular custom). What happens after the introduction of a special code. You can learn it from the manufacturer, supplier, seller, in service centers and in many other ways;

- By pressing the “-” button set the desired power value.

An important advantage of the described method of reducing gas consumption is simplicity. Since almost any boiler user will be able to cope with the task. We recommend that you familiarize yourself with gas flow measurement methods.

The disadvantage is that when the boiler power is reduced, its efficiency decreases. As a result, if the adjustments are changed downward to a moderate value, this will be a reasonable compromise. Which will help to benefit from fuel economy.

In the same way eliminate impulse work boiler (its timing). Which is a common cause of excessive energy consumption.

At the same time, if you make an excessive decrease in the productivity of gas equipment (from maximum to minimum), the reduction in efficiency will be expressed in tens of percent of the optimal value. Which, again, will lead to additional and unnecessary costs.

Method # 2 - automatic adjustment

Cost-effective and efficient is the adjustment of the power of gas boilers using the so-called weather-dependent automation. Its feature is that the package includes external and internal temperature sensors. That is, when choosing the optimal operating mode, the indicators obtained during measurements on the street and inside heated rooms are taken into account, or rather compared,. That allows you to change the power of the boiler even before the air overheats in the rooms.

Example: with the onset of morning, the frost outside decreases, but at the initial stages of warming, internal sensors do not record temperature changes. Therefore, the boiler continues to operate with constant performance. But after a couple of hours this will lead to overheating of the indoor air, which means that part of the gas will be wasted.

At the same time, the use of an external temperature sensor will cause a temperature increase to be detected in a timely manner. This will allow to reduce the boiler power in advance. That is, it will not come to overheating the air. And this will provide a more economical gas consumption.

Manufacturers produce sets of weather-dependent automation for most of their modern boilers. But in most cases, it is not included in the basic package. That is, if necessary, the specified equipment will have to be bought.

Both of the above adjustment methods are quite efficient. But you should be aware that the maximum benefit from them will only be if the gas boiler, as well as related equipment (for example, ventilation, smoke exhaust, etc.) is correctly selected, technically sound and works normally.

Otherwise, the use of adjustments will simply be a disguise for the existing problem.And to solve it, you have to look for other ways.

Effective methods to reduce gas consumption

Reasons that significantly affect decrease in efficiency of gas boilers, and, accordingly, to increase fuel consumption, quite a lot. Therefore, the user should initially identify one that adversely affects the performance of gas equipment. In order not to experiment, using the trial and error method to reduce power.

Moreover, often all that is needed to identify a problem that prevents the boiler from operating in optimal mode is to conduct a visual inspection of it. What can be done in a matter of minutes by either an employee of the gas service, a specialized company, or a person who owns only a basic set of specialized knowledge.

And after identifying the problem, you should choose one of the appropriate options for resolving it. Which we will consider in detail below.

Method # 1 - eliminating the causes of chemical underburning

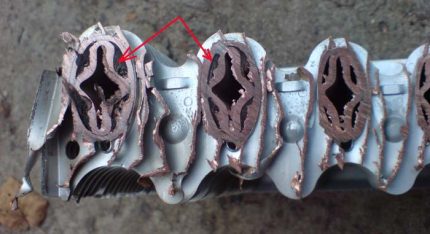

Such important structural elements of any heating device as a heat exchanger, burner are often covered with soot, sintered dust and other types of pollution.

As a result, there is a decrease in the efficiency of heat transfer. Therefore, in order to reach the set temperatures, the gas boiler has to work for a longer time. Which leads to an increase in energy consumption.

The reason for the clogging of the structural elements of the gas boiler is the burning of “blue” fuel. This phenomenon occurs when an insufficient amount of air enters the combustion chamber of the heater. The result of which is incomplete combustion of gas.

The problem is fixed in several stages:

- Carbon removal from heat exchanger surfaces, gas burner and other elements of the boiler design.

- Cleaning ventilation ducts. Moreover, this is a mandatory procedure. Since it is the inefficiency of the ventilation system that often leads to the fact that insufficient air is supplied to the gas burner.

- Cleaning the channels of the smoke exhaust system. This procedure is necessary due to the fact that the lack of oxygen can lead to inefficient removal of combustion products.

The specified manipulations can be performed by specialists of the gas service, specialized companies, as well as the owner of the boiler. But provided that he has sufficient knowledge and skills.

If the structural elements of the boiler and air ducts are cleaned, and carbon deposits continue to form, and very quickly, then the problem of under-burn and inefficiency can be solved with:

- commissioning;

- arrangement of ventilation systems, smoke removal.

Since commissioning is simpler and less expensive, you need to start with them. Why do you need to invite a gas specialist or a company that has the necessary license.

Arrangement ventilation systems, smoke removal begins with calculations. They make it possible to understand how much air is needed to eradicate such a phenomenon as under-burning, followed by excessive gas consumption.

For stable provision of the boiler with the required amount of air, it is better to use modern equipment (coaxial or sandwich ducts).

Method # 2 - eliminating the causes of mechanical underburning

This phenomenon occurs when part of the gas simply does not have time to burn out due to excess oxygen, while the surfaces of the boiler remain clean.

That is, the situation is the opposite of what happens with chemical underburning. And it is caused by the excessive performance of the smoke exhaust system, which leads to high traction. Which should be adjusted to eliminate the causes of incomplete combustion of "blue" fuel. What, with a traction limiter, can be done in seconds.

If the specified device is not provided, then using modern modular smoke removal systems, this drawback is easy to fix.

To solve problems with excessive traction, you can think about changing the type of smoke exhaust system, for example, to modern coaxial ducts with the right diameter. This will be a practical solution - the optimal dimensions and the absence of a restrictor, which is a transverse partition, will make the air flow more stable. What will affect the quality of gas combustion.

In addition, the causes of mechanical underburning, and, consequently, gas overruns, can be:

- incorrect power setting;

- incorrect choice gas boiler power.

In the first case, the problem can be eliminated by setting the heater in manual mode. How to do this is described at the beginning of the article.

Method # 3 - cleaning the heat exchanger and coolant

On the inner surfaces of the channels of the indicated structural element of the boiler, plaque is deposited, consisting of ferric iron, salt deposits and other foreign particles. This can lead to the fact that in order to warm up the coolant to the required temperature, it will be necessary to spend more thermal energy after several months from the start of operation. To develop which you will need increased gas consumption.

Even when installing a gas boiler, you should take care of the correct commissioning. Since a poorly tuned fuel valve, nozzle or electronics will not give the expected result. Moreover, from the first day of using the heater, in order to eliminate this drawback, the internal cavity of the heat exchanger must be regularly cleaned.

What can be done in various ways:

- mechanical, i.e. manual cleaning;

- chemical, for which special solutions are used;

- hydrodynamicthat is carried out using ordinary water (under pressure).

Mechanical cleaning the heat exchanger is made using various brushes, scrapers. That is, with certain skills, this procedure will be able to be performed independently, although it is labor-intensive.

Chemical the way cleaning consists in the fact that a special device called a booster is connected to the dismantled heat exchanger. And it repeatedly spills the internal channels with special fluids (acids). Which cope even with the most resistant plaque.

Hydrodynamic the way is the least labor intensive. Since all that is required when using it is to connect a special pump to the heating system. Then pure water is pumped into its channels, the pressure of which gradually increases. Which leads to stratification and subsequent removal of plaque.

The heat exchanger channels must be cleaned at least once every 2 years. To reduce the frequency of the specified procedure is possible only when using filters that are used to clean the coolant from all kinds of dirt particles. That allows you to clean the heat exchanger 2 times less often, that is, every 4 years.

To clean the coolant, you can use filters:

- rough cleaning;

- fine cleaning;

- magnetic.

All of these products can be used both together and separately. But the optimal combination of filters can only be established after laboratory analysis of water, which will be used as a coolant.

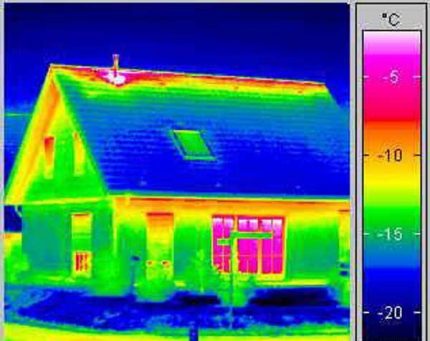

Method # 4 - reducing overall heat loss

If a gas boiler consumes gas disproportionately, but there are no external signs of a problem and it is correctly configured, then we can assume that the problem is not in the unit itself. And all the blame total heat lossto be eliminated. Otherwise, energy overruns cannot be avoided.

The causes of common heat loss are:

- improper installation of radiators;

- non-optimal total heat output of radiators;

- poor thermal insulation of doors, windows;

- lack of insulation of floors, roofs, walls of the building;

- insufficient thermal insulation of ventilation ducts, smoke exhaust, others.

You should know that the efficiency of any gas boiler directly depends on the correct operation of radiators. And the worst news is that to achieve a reduction in energy consumption by any manipulations with the heating boiler, with improper installation of radiators, it will not work.

Therefore, it is necessary to proceed to the indicated question as soon as it becomes clear that the boiler is serviceable and correctly configured.

When checking the correct installation of radiators, make sure that:

- Skewed. This is an important point, since the heatsink roll of more than 1 ° begins to affect the efficiency of the heating system. And significant inaccuracies made during the installation of several products will lead to a significant loss of efficiency, and by tens of percent;

- Batteries are located in places where the heat loss is usually greatest. (for example, at windows). And placed 12 cm from the floor, 2 cm from the wall and 10 cm from the windowsill, which should overlap the radiator by 2/3.

And also pay attention to the absence of excessive bends in the places of rotation of the pipes through which the coolant flows, the correct installation air vent valves.

As already indicated, the total thermal power of the radiators and the gas boiler used should be approximately equal.

If this rule is not observed, then at a low total power the gas boiler will heat the coolant to critical 75 ° C. At which quick wear of all the structural elements of the heating system made of polymer plastics will begin. What threatens leaks.

In addition, at this temperature, dust particles massively burn out, which does not contribute to the comfort of living.

And the worst thing is that the difference in the performance of the equipment that is used as part of the heating system will lead to clocking (frequent on / off). At which a considerable part of the gas will simply fly out into the pipe without burning out. The reason is that the electronics of all boilers are programmed so that gas is supplied first, and after some time a spark is produced.

In addition, when turned on, the performance of gas boilers traditionally reaches peak values, which is designed to eliminate problems during their ignition. And this feature with frequent launches leads to even greater losses.

It should be remembered that the efficient operation of gas boilers in a room equipped with windows, doors with cracks, cracks and not insulated walls, floors, ceilings cannot be. That is, the listed disadvantages should also be eliminated.

The importance of boiler maintenance

Effective methods that allow solving such a problem as reducing gas consumption by the boiler were listed above. But they all have an unpleasant feature. The reason is that the procedures described are used when the heating unit, and with it the entire heating system, has become less effective. Which leads to increased fuel (gas) consumption and reduced living comfort.

And such a disadvantage can be eliminated only through maintenance. The main feature of which is the ability to prevent an increase in gas consumption, as well as prevent premature wear of structural elements of any gas boiler. That allows you to save even more.

The specified procedure is a complex of various works, namely:

- control;

- verification.

Which allow you to timely identify signs of all problems leading to a decrease in the efficiency of boilers. The exception is only the clogging of the heat exchanger channels, since it cannot be visually detected. Therefore, in this case, you just need to combine the cleaning work with maintenance (with the right frequency).

Maintenance must be performed at least once a year before the start of the heating season. But it is more practical to carry out maintenance up to 3 times for every 12 months:

- before seasonal operation;

- during its operation;

- after the end of the heating season.

An important advantage of boiler maintenance is that its owner can carry out a significant part of the work. Since all that is needed is to have a certain set of knowledge and practical experience.

Conclusions and useful video on the topic

The first video material will allow you to better understand the reasons that lead to an excessive consumption of energy by the boiler.

The next video talks about how to reduce the consumption of "blue" fuel to a minimum.

It is quite realistic to reduce gas consumption by a domestic boiler, and in many cases this can be done quickly and without financial costs. But it should be remembered that the most effective method is regular maintenance.

In addition, when performing any work on gas equipment, one should not forget about security measures.

Do you want to supplement our material with useful comments or tell your secrets to reduce gas consumption? Or do you still have questions about reducing fuel consumption by a gas boiler? Add your comments, ask for advice from our experts and other visitors to the site - the feedback block is located below the article.

Floor boiler gas consumption: daily standard consumption + calculation example with formulas

Floor boiler gas consumption: daily standard consumption + calculation example with formulas  How to increase the efficiency of a gas boiler with your own hands: the best ways to increase the efficiency of the boiler

How to increase the efficiency of a gas boiler with your own hands: the best ways to increase the efficiency of the boiler  Replacing a gas boiler in a private house: norms and rules for completing the procedure for replacing gas equipment

Replacing a gas boiler in a private house: norms and rules for completing the procedure for replacing gas equipment  Voltage stabilizers for a gas boiler Baxi: TOP-12 of the best models according to consumers

Voltage stabilizers for a gas boiler Baxi: TOP-12 of the best models according to consumers  Immergas gas boiler errors: error codes and solutions

Immergas gas boiler errors: error codes and solutions  Repairing a gas boiler valve: how to fix a unit by correcting a typical malfunction

Repairing a gas boiler valve: how to fix a unit by correcting a typical malfunction  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements