Schemes of a steam heating device + example of calculation of a steam system

Owners of private homes will certainly encounter the issue of heating their homes. Everyone is trying to choose an option that allows high-quality heating of the room, while consuming a minimum amount of fuel.

Many owners of suburban real estate and country houses are attracted by the steam heating scheme, in which steam is able to heat the room in a matter of minutes. Before deciding to equip such a system, it is necessary to study the features of its work, to compare all the pros and cons.

We will help to understand these issues. And also we will describe different schemes of steam heating, we will give the calculation methodology and the rules of the system.

The content of the article:

Steam heating: schemes and features of the device

Without a heating system, life in a country house in the autumn, spring and, especially, winter months is impossible. Often for cottages, periodically visited by the owners, choose the option of steam heating.

It is able to provide very fast heating of the whole house, which will pleasantly please the owner and his guests, who decided to spend a weekend in the country.

Principal features of steam heating

It is convenient to arrange steam heating in houses rarely visited by the owners. All thanks to the features of the coolant circulating through the pipes. This is a pair that appears only when the boiler is operating.

Indeed, when no one is in the country, and the street has a frost of -15 ° C or more, you don’t have to worry that the pipes will burst, as is the case with water coolant.

Steam heating has its advantages:

- a large amount of heat released during condensation;

- require a smaller area of heat emitters in the room;

- quick start and stop of the system;

- saving money on heating;

- frost resistance.

As for the amount of heat released in the process of steam condensation, it is many times higher than the heat given off by the heated water circulating in the heating system.

1 kg of steam at a temperature of 130 ° С during condensation releases energy equal to 2300 kJ / kg. As for the volume, the condensate takes up 400-1500 times less space than the same mass of steam.

This feature allows the use of pipes of smaller diameter. In small rooms, you can do without batteries - the heat emitted by the pipe will be enough to heat them.

Another feature is the rapid heating of the room. Conveniently, when you get out of town for a few hours, you don’t have to deal with heating for a long time. The saved time can be used for more pleasant hassles, for example, frying a kebab and chatting with friends for a longer time.

Leaving the dacha in the cold season, you do not need to spend time on preserving the heating system, draining water and other measures designed to protect the system from failure.

In the absence of fuel in the steam boiler, steam does not enter the steam line. Accordingly, there is no water in the condensate line. Therefore, there will be no problems with freezing the system.

Disadvantages of a steam heating system

Steam heating, in addition to its advantages, also has disadvantages.

Firstlyhigh degree of danger. This is due to the specifics of the coolant.

When steam goes through the pipe under pressure, then:

- when breaking the steam line, it can seriously injure a person;

- if you accidentally touch the surface of the pipe or battery, it is easy to get a burn;

- improper use of heavy-duty equipment can explode.

Secondly, baking dust falling on the surface of the steam pipe. Under the influence of high temperature, dust particles decompose.The products of their decay negatively affect the inhabitants of the house, especially if there are allergic people among them.

Thirdly, the dry air that all the inhabitants of the home are forced to breathe. To improve the indoor climate, pick up a humidifier. This is an additional expense item, which should be provided even at the stage of designing the heating system.

Fourth, the temperature of the coolant is simply impossible to regulate and reduce at will. This disadvantage creates many difficulties when using the steam heating system in homes with permanent residence.

The way out of this situation is the laying of several branches of the steam pipeline with their subsequent inclusion in the work as necessary.

Fifthly, it is necessary to use special steam fittings designed for working with steam. The same applies to the material of pipes and radiators.

It should be borne in mind that the service life of the condensate pipeline will be much shorter when compared with water heating, where return pipes from the same material are installed. This is especially true for dry condensate pipelines.

At sixthcare should be taken to ensure proper wall decoration. After all, paper wallpaper does not have the desired level of heat resistance. Cement plaster painted with appropriate paint is suitable here.

Another interesting option is loft-style decoration. To do this, the inner wall surface, along which the steam pipe will pass, can be laid out from heat-resistant bricks. This will not only create a unique atmosphere, but also protect residents when a hot pipe affects the wall material.

Seventh, need in equipment for a boiler room. It is not permissible to place the steam boiler in the living room. It is very dangerous. The location of the boiler must be equipped with heat-resistant materials and well ventilated.

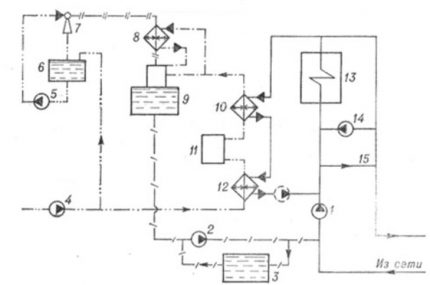

Steam Heating Schemes

The heating option using steam as a heat carrier has a variety of schemes.

They can be classified by the following parameters:

- system pressure;

- a way to communicate with the atmosphere;

- pipe connection diagram;

- condensate return method.

The pressure in a functioning steam heating (PO) system can be higher and lower.

Depending on its absolute value, the following systems are distinguished:

- low pressure - less than 0.7 kgf / cm2;

- high pressure - more than 0.7 kgf / cm2;

- vacuum steame - less than 1 kgf / cm2.

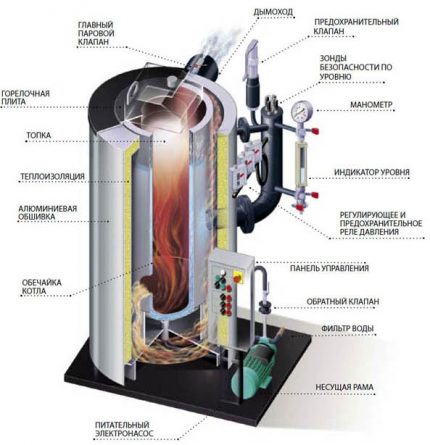

The first option is recommended for domestic use. Special boilers designed for steam heating allow you to implement a low pressure system in private house or in the country. They can operate on various types of fuel - coal, wood, gas, fuel oil.

The second option is dangerous for use at home. To work with high pressure systems, appropriate knowledge and specialization are required. If an unprepared craftsman decides to collect high-pressure steam heating in his country house, then he risks staying, at best, without a cottage.

A high pressure boiler is large and very expensive.This option is used in industry. But many home craftsmen experimentally try to implement a similar installation with their own hands. This option is extremely dangerous to use in the heating system.

The vacuum-steam system differs from the first two by the presence of an air collector and an additional device that ensures the evacuation of the entire internal space.

Depending on the method of connecting with the atmosphere, open and closed steam heating circuits are distinguished. In the first case, the system has a connection with the atmosphere - it is open. In the second, it is completely isolated from atmospheric pressure and air from the environment.

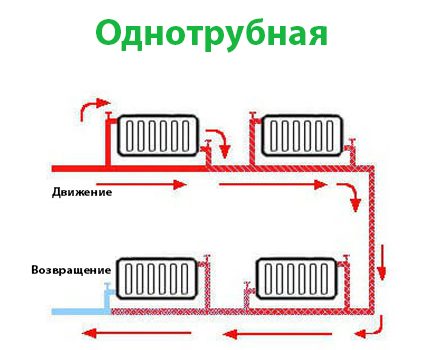

According to the method of piping tracing, software schemes are:

- horizontal single pipe;

- vertical two-pipe.

The former are used, as a rule, in one- and two-story houses and structures with ceiling heights of up to 2.7 m and an area of up to 80 m2where you do not need to adjust the temperature. The second is more suitable for the implementation of a steam heating system in buildings with 3 or more floors.

Moreover, software systems can be mounted:

- with upper, middle or lower wiring;

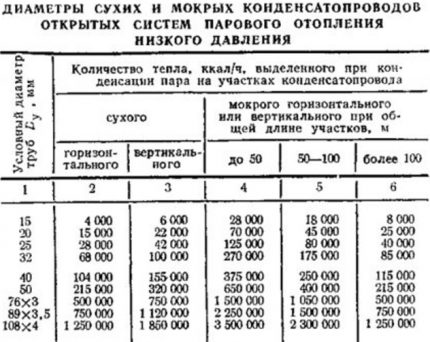

- with wet or dry piping for condensate movement;

- with deadlock or associated movement of both steam and condensate.

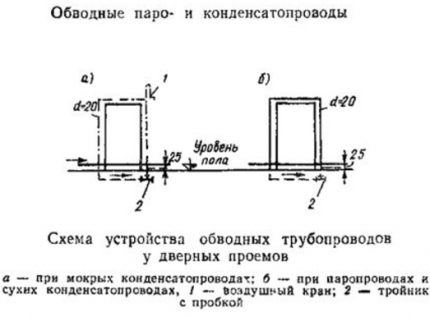

The condensate return method allows you to select a closed and open circuit. In the first case, the water formed in the condensation process is directed by gravity into the boiler. In this case, the recommended slope of steam and condensate pipelines must be maintained - from 1.0 to 0.5 cm slope per 1 running meter.

Moreover, the bias is correctly done in the direction of steam movement for the steam line and in the direction of condensate movement for the return pipe. The boiler itself with this scheme must be located below the level of the return pipe.

In the circuit of an open steam heating system there is a special tank for collecting condensate - a tank. From it, with the help of a pump, liquid can be sent to the boiler or removed from the heating system. In the second case, the boiler must be constantly fed with fresh water for the continuous formation of steam.

It is preferable for a country house to choose a closed steam heating circuit with an upper wiring and a wet condensate pipe, i.e. the entire volume of the channel filled with water. For open circuits, a dry pipeline variant is used to partially move condensate filled with condensate.

How to calculate the steam system correctly

Having chosen the steam system, it is necessary to draw up a project of its location in the building and perform preliminary calculations.

There are two options:

- to calculate the main components of steam heating on their own;

- Seek help from a professional designer.

The second way to resolve this issue is most preferable.After all, only a specialist, having more than one successfully implemented project for arranging a heating system, is able to take into account all the wishes of the owner, not forgetting the regulatory requirements.

If there is no possibility and desire to contact the designer, you can proceed to the independent calculation of the steam heating system. You can use the standards and useful recommendations from the specialized literature, for example, from the designer’s guide.

To calculate, you have to take the plan of your house and calculate the area that you want to heat. Then mark the locations of the radiators.

Radiators are selected depending on the required power. Moreover, it is important to consider the technical characteristics of the device you like - it must withstand the load when working with steam.

It is best to calculate the length of the steam and condensate piping while in the room itself. So it’s more convenient to plan the height of their gaskets and the location of the radiators, if necessary.

After calculating the required number of linear meters of the pipe, do not forget about steam valves - valves, tees, and, if necessary, steam traps, a pump.

To determine the capacity of a steam boiler, it will be necessary to calculate the volume of all heated rooms and multiply this figure by the indicator of the required amount of energy for heating 1 m3. This indicator depends on the region of residence. So, for the European part, the figure is 40 watts.

You can calculate the boiler capacity for a 3-bedroom house with a ceiling height of 2.6 m.

First you need to calculate the area of individual rooms:

- 1st room: 5 * 2.95 = 14.75 m2;

- 2nd room: 3 * 2.45 = 7.35 m2;

- 3rd room: 2 * 5.4 = 10.8 m2.

Then you have to calculate the volume of the whole house: 14.75 * 2.6 + 7.35 * 2.6 + 10.8 * 2.6 = 38.09 + 19.11 + 28.08 = 57.02 m3.

Now the obtained volume must be multiplied by the heat demand: 57.02 * 40 W = 2288 W. To the obtained value it is necessary to add a power reserve of at least 20%: 2288 * 1.2 = 2745.6 W or about 3 kW.

The second option for determining power is by area. It is conditionally accepted that for heating every 10 m2 1 kW of boiler power + 30% of the reserve is required if the ceiling height does not exceed the permissible level of up to 2.7 m.

Moreover, you need to buy the unit 20-30% higher than the calculated power size. In practice, experts advise taking a boiler no less than 30% more powerful so that it does not work to the limit of its forces.

Select a steam boiler from a trusted manufacturer. The unit must have a certificate of quality and a guarantee of the plant that produced it. Steam boiler must be equipped safety valve. Also, temperature and pressure monitoring devices and a pressure reducer are needed to normalize the pressure, if necessary.

Errors with steam heating

Being engaged in the device of individual heating, it is necessary to carefully study the existing options.

To choose for your home ownership is the most suitable option in order to further receive:

- economical fuel consumption;

- efficient heating;

- convenience of system maintenance;

- long service life of the equipment.

Stopping among all the options for heating on steam, it is important to try to avoid mistakes made during its construction.

Firstly, most often, home owners believe that water serves as the coolant in the system. This is not true.When heated by steam, it will be steam that flows through pipes and batteries.

Proceeding from this, it is necessary to choose the right material for the reinforcement with which the steam and water obtained during condensation will come into contact.

Secondly, even at the stage of designing the heating system, they forget to provide protection for batteries and pipes. Steam moving through a steam line has a temperature of 100 ° C. It heats all structural elements sufficiently strong, which is dangerous for residents of the house / cottage.

Thirdly, when installing the steam and condensate pipelines, novice masters forget to foresee a bias towards the movement of steam and water, respectively.

Fourth, Some home craftsmen incorrectly select the power of the boiler. As a result, instead of the desired room temperature, + 13-15 ° C is obtained. For daily comfortable living, such a temperature regime is clearly not enough.

FifthlyInexperienced welders can make a mistake when welding a steam pipe. As a result, at any time, the pipe can break through and the steam flow moving under pressure through it will rush directly to a person who is nearby. This is an extremely dangerous situation, the possibility of which should not be forgotten.

All of these errors are likely when self-arrangement of the system heating. Wanting to save money and choosing the option with steam, the owners decide to cope on their own, deciding not to contact a professional designer, welder and other specialists.

Lack of personal practical experience and a frivolous attitude to the process can interfere with the proper installation of steam heating. Some of the mistakes made during installation can not only disrupt the usual way of life, but also seriously harm the health of those living in the house.

Conclusions and useful video on the topic

Video material about the device of the steam boiler:

A clip on how to weld pipes:

Visual video about the features of installation and soldering of copper pipes:

Steam heating video:

Detailed video about the operation of the steam boiler:

After reviewing the positive and negative sides of steam heating, you can decide whether this option is suitable to meet the needs of a particular home ownership.

If you decide to use steam heating, you have to choose the most optimal scheme for your home. To calculate the heating system, it is better to contact specialists in order to protect yourself and the household.

If you have experience heating a house using a steam heating system, please share this information with our readers. Leave comments on the article and ask questions in the form below.

Two-pipe heating system of a private house: device diagrams + overview of the advantages

Two-pipe heating system of a private house: device diagrams + overview of the advantages  How are heating systems with pump circulation arranged: organization schemes

How are heating systems with pump circulation arranged: organization schemes  Closed heating system: schemes and installation features of a closed type system

Closed heating system: schemes and installation features of a closed type system  Natural circulation heating system: common water circuit designs

Natural circulation heating system: common water circuit designs  How the radial heating system works: schemes and wiring options

How the radial heating system works: schemes and wiring options  One-pipe heating system Leningradka: schemes and organization principle

One-pipe heating system Leningradka: schemes and organization principle  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Extremely dangerous and expensive heating system. A couple of years ago, when I threw new communications in my country house, I was advertised this option for heating the house. I doubted for a long time, but nevertheless made a choice in favor of a traditional system with a liquid coolant and an electric boiler. But the neighbor decided to test the steam technology on himself.He says that he regrets his choice, since the annual maintenance of the boiler and the entire heating system flies to him “a pretty penny”. He thinks in the near future to switch to electric heating.

I found a lot of new, interesting and useful for myself in this review. I have a two-story house, a water heating system with a boiler and wiring on two floors. There is such a problem: in severe frosts, below 30, the first floor is much cooler than the second, as the heat rises up. I thought, maybe it makes sense to add a steam heating circuit to the lower floor and use it in cold weather. Can someone share their experiences?

Hello! The problem is clear to me, but not completely. The second floor in your house is warmer during severe frosts. But you did not write a word about the temperature of the radiators. If it is the same, on the first floor, on the second, then you need to think about warming the house. This is a separate issue, so we will not dwell on this issue. At the same temperature, the radiators on the ground floor can only be colder due to heat loss.

If on the ground floor the system warms less, then you need to redo or upgrade it. But to begin with, it is worth checking whether everything is working properly: wherever the pipes are clogged, to check the correct operation of the air vents (if there are none, install it). If this does not help, then proceed with the modernization: add a contour, a hydraulic arrow, redo the return (depending on the situation). I attach several heating schemes for a two-story house as an example.