Installation of a water supply system from polypropylene pipes: typical wiring diagrams + installation features

Metal pipes are no longer considered the only right solution for organizing intra-house utilities. Increasingly, owners of households rely on the installation of water pipes from polypropylene pipes, which are distinguished by their affordability and durability.

The choice promises lower financial costs, and the criteria for the maintenance and operation of polypropylene seem more attractive compared to metal. But before proceeding with the assembly of the water circuit, it is necessary to find out the features of the choice and installation of polymer pipes, agree?

The article is devoted to the solution of these questions. We described the characteristics of different products of pipe rolling, gave a decoding of their marking and designated working wiring diagrams. In addition, the article provides detailed instructions for assembling the highway, and also lists the technical nuances of the installation of a water supply system from PP pipes.

The content of the article:

Distinctive features of polypropylene pipes

A seemingly complicated water supply system made of polypropylene pipes can be done independently. But first, it is advisable for the plumber master to get as much information as possible on the topic of installing a water supply system based on PP pipes.

Since the main element of the installation process is polypropylene pipes, it should be remembered that there are products on sale:

- PN10 - single-layer for pressure up to 10 ATI;

- PN20 - single-layer pressure up to 16 ATI;

- PN30 - three-layer for pressure up to 25 ATI.

PN10. The first type of polypropylene hoses for a working pressure of up to 10 atmospheres is quite suitable for the installation of a cold water supply line for the domestic sector and the construction of water heated floors. Of such material, a cold water supply system with a working pressure of up to 10 atmospheres is usually mounted.

PN10. Pipes are designed for operating pressures up to 16 ATI; they are also used for wiring of cold water lines. They can also be used for the construction of hot water pipelines, if the limit temperature in the system does not exceed + 60ºС.

PN20. The modification is represented by more durable products, suitable for mounting not only cold and hot water supply systems, but also heating circuits. Such polypropylene can be used in systems with high working pressure (up to 20 ATI) and a coolant temperature of up to + 80ºС.

PN25. it pipes for heating systems, but can also be used for domestic hot water. Made on the basis of the same three-layer technology. Only the reinforcing layer is made of aluminum foil. Maximum value of working temperature + 95ºС.

Products under the PN25 brand are positioned as an innovative development, thanks to which it was possible to get rid of a significant drawback of polypropylene sleeves - thermal expansion. In fact, these products are a universal product that can be used for any type of water supply system.

You should take into account the peculiarity of the installation of such pipes - when soldering, the reinforced layer is removed. Only a polypropylene base is to be heated with a soldering iron.

The entire existing range of polypropylene pipes for water supply, as a rule, is marked on the basis of a specific purpose.

Typically, markings are colored stripes applied directly to the outer wall of the pipe:

- blue / green under the cold water

- red / brown for domestic hot water or heating,

- orange under any water supply system.

Color marking facilitates pipe selection.

Typical wiring diagrams

There are many circuit decisions regarding the layout of water lines from propylene. Each of a single scheme is usually considered taking into account the financial costs of the construction and taking into account the technical requirements for the premises of the facility.

Most often, the classic wiring diagram is used, the same type with respect to the cold water and hot water lines.

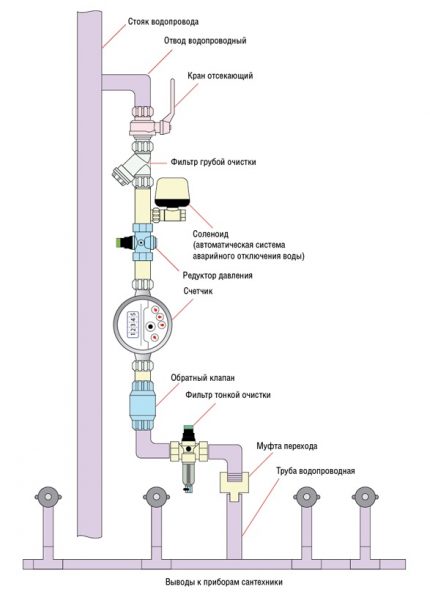

Water is supplied from the riser of the centralized main by pipe discharge with a stopcock installed on it. Then, system elements are mounted in series: filter, gearbox, meter, check valve and connected to the distribution manifold.

From the collector, cold or hot water is distributed among plumbing fixtures. This solution is traditionally used for water distribution in the apartment.

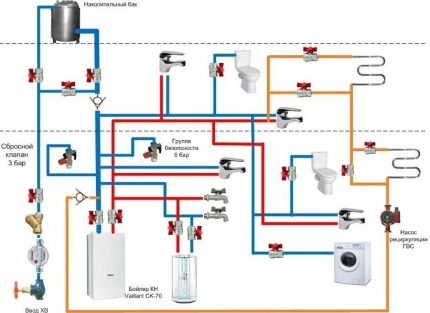

Many private households use an autonomous water supply system. Therefore, a departure from traditional circuit solutions in such cases is not excluded. But usually the principle of collector distribution for water supply systems (not heating) is maintained in any case.

Private home boiler systems often only provide cold water. Moreover, a well can serve as a source of cold water instead of a centralized highway. Then the wiring diagram can be approximately as follows:

The wiring diagram in any case should include the presence of shut-off (shut-off) valves for each individual plumbing fixture. For autonomous type circuits (with boilers or boilers), the mandatory presence of bypass lines on devices that perform the functional process is characteristic.

Such solutions allow you to quickly switch the system from offline to centralized supply if necessary.

Read more about wiring the water supply in a private house is written in this article.

Features of the installation of pipes made of polypropylene

The installation of a water system based on polypropylene pipes, as a rule, is accompanied by the acquisition of a special tool and a set of elements - fittings, which ensure full-fledged installation. Special tool - soldering iron polypropylene pipes - You can buy or rent more reasonably.

The installation of a water supply system from PP pipes requires compliance with a number of technical and technological nuances:

From a set of necessary tools pipe cutter (special scissors). However, it is quite acceptable to cut polypropylene sleeves with a hacksaw for metal. For measurements, you will need a construction tape measure, as well as a marker (pencil) or something similar.

An angle ruler or protractor will not be superfluous in the installation business. For a complete set, you also need wrenches or an adjustable wrench.

The process of assembling polypropylene pipes does not require any special technological actions from the plumber. But, any experience with soldering polypropylene is still necessary. A complete lack of skills threatens to turn into unpleasant consequences of running a water supply system in the future.

And the sequence of work is approximately the following:

- The pipe of the water supply line is cut to size.

- The place of cut and connection is cleaned from burrs.

- The necessary fitting element is selected and adjusted.

- Polypropylene soldering iron is equipped with appropriate nozzles.

- Turn on the heating at the soldering station - heating limit 260ºС).

- The abutting elements (fitting and pipe end) are brought into contact with the nozzles.

- They are heated for several seconds (4-10), depending on the wall thickness.

- Remove from the nozzles and quickly quickly manually connect by inserting the end of the pipe into the body of the fitting until it stops.

The peculiarity of the last action is that it must be performed quickly enough with a clear fixation of the pipe and fitting in one position. After connecting the elements, wait at least 30 seconds. This time is enough to harden the heated areas and tightly connect them to each other.

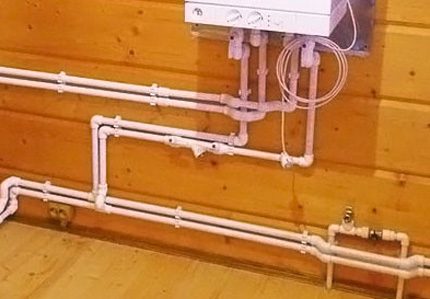

Properly considered is the installation of any type of water supply system from polypropylene pipes, when the lines are drawn from plumbing fixtures to the main source of water. Pipes should be installed as straight as possible, parallel to the floor or walls of the building.

If the domestic hot water and domestic hot water lines are located in close proximity to one another, it is recommended to install the domestic hot water line above the domestic hot water line.

Polypropylene pipes, when compared with a metal pipe, have significantly lower rigidity. Therefore, when installing polypropylene, attention should be paid to the reliable fastening of pipelines to the base. Fixing support brackets must be placed every 1.5-2 m of the pipeline line.

It is desirable to build water mains taking into account the minimum loads on the pipelines. It is not recommended to bend the body of the polypropylene pipe, heating the bend, in order to bypass the obstacle in this way. To solve such problems, you should use special fittings - corner or bypass.

Bell-shaped connection of parts of a polypropylene pipeline produce welding method:

Fittings PP water supply systems

The term fitting is taken from English. Translated literally: mount, fix, do the assembly. Structurally, the fitting is a component of the pipeline, in particular, made of polypropylene.

This component can take the form of a corner (90º or 120º), tee, cross, etc. There are fittings with threaded inserts for connecting shut-off and other valves. There are special bypass elements that allow you to carefully bypass the places where one pipe bumps into another.

Using any of these mounting elements, it is convenient to build piping layouts in almost any configuration. So, in order to connect in a straight line one polypropylene pipe to another, a sleeve is used.

The same fitting is used if you need to make a transition from a pipe of one diameter to a pipe of another diameter on a straight section. It is easy to connect the pipes to the turn with the help of corner fittings.

Are issued various fittings for installation of water pipes by polypropylene pipes. If one type of such elements is intended to be used for soldering, another type is used for mechanical threaded connections.

Fittings for a mechanical threaded connection allow using a power crimp method to create a completely durable reliable connection, eliminating soldering technology from the process.

In addition to the threaded connecting technique, the technology of gluing water pipe parts is often used. For example, using special glue, tees and polypropylene pipes, you can easily make a distribution manifold for cold water with your own hands.

The actions of the master plumber in this case are reduced to the following steps:

- The pipe is cut to size and deburred.

- The surface of the pipe at the junction is degreased.

- A layer of glue is evenly applied to the surface.

- The end of the pipe is inserted into the fitting until it stops.

The drying time of the glue is 20-25 minutes.

Conclusions and useful video on the topic

Useful tips for the correct welding of PP pipes you will learn from the following video clip:

Obviously, the introduction of polypropylene pipes into the constantly used plumbing materials was a kind of technological revolution. From now on, it became possible to build water pipelines with a high economic effect. At the same time, reliability and quality remained at the level of the same metal pipes.

The only limitation for propylene is temperature. But in the domestic sector, temperature parameters are consistent with the characteristics of polypropylene pipes.

Do you have personal experience in installing water pipes from polypropylene pipes? Want to share your knowledge or ask questions about the topic? Please leave comments and participate in discussions - the feedback form is located below.

DIY installation of polypropylene pipes: technology for working with PP piping

DIY installation of polypropylene pipes: technology for working with PP piping  Do-it-yourself installation of plastic pipes: connection technology and wiring examples

Do-it-yourself installation of plastic pipes: connection technology and wiring examples  Soldering polypropylene pipes: work rules and analysis of possible errors

Soldering polypropylene pipes: work rules and analysis of possible errors  DIY welding technology for polypropylene pipes: an overview of methods and nuances

DIY welding technology for polypropylene pipes: an overview of methods and nuances  How to make a chair from polypropylene pipes with your own hands: step-by-step instructions for manufacturing

How to make a chair from polypropylene pipes with your own hands: step-by-step instructions for manufacturing  Replacing pipes in the toilet from A to Z: design, selection of building materials, installation work + error analysis

Replacing pipes in the toilet from A to Z: design, selection of building materials, installation work + error analysis  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

HM interesting! I didn’t even know that there is such a technology for gluing water pipe parts. Usually, everything is screwed onto a threaded connection. It will be necessary to implement this technique in our team)

A mobile soldering iron is a thing you need! I don’t need to carry pipes all the time for soldering, as I remember in the 90s we had a soldering iron of 40 kg weighed. There is not a soldering iron, but almost a machine. Now of course hoo technology !!

Yes, technology, of course, is a class. I even mastered it already. In summer, he replaced the water supply in the house. First I learned the instructions from the Internet. Here Sanya in the video taught how to solder polypropylene pipes. I bought a soldering iron, pipes, elements for docking, and go. Everything turned out as it should. The only inconvenience was that a very unpleasant, strong odor of molten polypropylene was released during the soldering process. I think that breathing is not only unpleasant for them, but also harmful.My wife grumbled that I wanted to poison everyone. It’s good that it was warm and all windows and doors were open. But I did not have to hire a welder, in terms of money, savings.

Installation looks pretty simple. But to buy or rent a soldering iron for PP pipes is a question. On the one hand, it’s not a fact that it will come in handy more than once, on the other hand, the price is adequate, you can buy it just in case.

In this article, I quote: “If the hot water supply and hot water supply lines are located in close proximity to each other, it is recommended that the hot water line be installed ABOVE the hot water line.”

And in the other, on the contrary - hot water over cold water. It seems more logical, since condensation will not form on the “hot” pipe.