Aspiration systems: types, device, installation selection criteria

Production processes are often accompanied by the release of dusty elements or gases that pollute indoor air. The problem will be solved by suction systems designed and installed in accordance with regulatory requirements.

We will understand how they work and where they are used such devices, what types of air-cleaning complexes are. We will designate the main working units, describe the design standards and the installation rules for aspiration systems.

The content of the article:

How it works

Air pollution is an inevitable part of many manufacturing processes. In order to comply with established sanitary standards for air purity, aspiration processes are used. With their help, you can effectively remove dust, dirt, fibers and other similar impurities.

Aspiration is a suction, which is carried out by creating in the immediate vicinity of the source of contamination a low pressure area.

To create such systems, you need serious specialized knowledge and practical experience. Although the operation of aspiration means is closely related to the functioning ventilation systems, not every ventilation specialist will cope with the design and installation of this type of equipment.

To achieve maximum efficiency, ventilation and aspiration methods are combined. The ventilation system in the production room must be equipped supply and exhaust complexto ensure a constant supply of fresh air from the outside.

Aspiration is widely used in such areas of industry:

- crushing production;

- wood processing;

- manufacturing of consumer products;

- other processes that are accompanied by the release of a large number of substances harmful to inhalation.

It is far from always possible to ensure the safety of employees with standard protective equipment, and aspiration may be the only way to establish a safe production process in the workshop.

The removal of contaminants using this type of system is carried out through special ducts that have a large angle of inclination. This position helps prevent the appearance of so-called stagnation zones.

An indicator of the performance of such a system is considered the degree of non-knocking, i.e. the ratio of the amount of contaminants that were removed to the mass of harmful substances that did not enter the system.

There are two types of suction systems:

- modular systems - stationary device;

- monoblocks - mobile installations.

In addition, aspiration systems are classified by pressure level:

- low pressure - less than 7.5 kPa;

- medium pressure - 7.5-30 kPa;

- high pressure - over 30 kPa.

The complete set of aspiration system of modular and monoblock type differs.

Monoblocks consist of the following elements:

- fan;

- separator;

- waste storage.

The separator is a filter for cleaning air passing through the device. The waste accumulator can be both stationary, i.e. built-in candy bar, and removable.

Such a unit can be purchased ready-made and simply installed in a place suitable for performing aspiration procedures. However, they are not difficult to connect to existing centralized systems.

Modular systems are more difficult to install and more expensive, but their use is much more effective than when using monoblock designs. Such systems are not typical, they are first designed taking into account specific conditions and tasks.

This takes into account a number of factors:

- characteristics of the production room;

- features of the process;

- quality of the transported medium, etc.

This is usually a centralized system that consists of duct set and suction unit. For large enterprises, a system can be used not with one, but with two or more such units.

The material of the ducts may be different, depending on the nature and amount of contamination that is supposed to be transported through them.

The most durable constructions are made of ferrous metal, but they are also the most expensive. In any case, individual sections of the air line are hermetically connected using bolted flanges.

Among the advantages of aspiration systems can be noted:

- relative simplicity of design;

- compatibility with various types of production equipment;

- environmental safety;

- the ability to automate the work;

- increase fire safety of the room, etc.

The disadvantages of such installations include, first of all, the increase in energy costs, especially with improper design, as well as the low resistance of metal ducts to wear. These points should be considered when choosing a suitable design.

Why design is needed

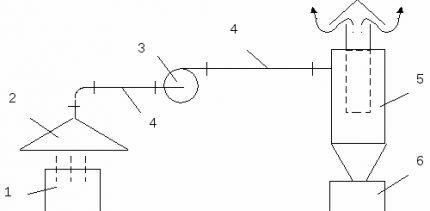

To create a modular aspiration system, the installation of the following elements is planned:

- local suction;

- inclined ducts;

- filter systems;

- high-pressure fan, etc.

As a local suction, various models of devices can be used, for example, airborne suction, “umbrella”, “shelter” structures and others.Air ducts are laid from the place of collection of waste to the point from moving to the outer space.

The filtration system can assume both the removal of cleaned air masses from the room, and their return after filtration to the fence.

Before drafting the suction unit, it is necessary to conduct a technical examination of the condition of the facility. At this stage, it is possible to identify and eliminate system deficiencies. Existing ventilation and aspiration systems can be subjected to a similar test.

The effectiveness of aspiration largely depends on the volume of air that passes through the ducts per unit time. The higher this indicator, the more expensive the installation of the structure, as well as the cost of its operation.

If you select the system components correctly, then the costs, both initial and operational, can be significantly reduced.

This includes the selection of a suitable device for suctioning air, competent calculations for the distribution of supply air, etc. As a result, the load on the system will decrease, filters will require less cleaning, the service life of fans will increase, etc.

Some owners of industrial facilities, when choosing a cleaning system, go along the path of least resistance. They start from the parameters of the cyclone type installation, simply informing the supplier of the conditions of its operation: air consumption and the nature of the pollution.

As a result, they get a device whose performance is selected according to the tables without taking into account other parameters. Experienced designers argue that this approach usually leads to increased costs and reduced equipment efficiency.

The cost of the cyclone installation is the higher, the greater the volume of air that moves through it. If you optimize an existing air distribution system, you can choose the suction and filters that will give the desired effect with less air consumption.

Such equipment will cost less, saving may be about a third of the total cost. That is why, before choosing equipment for an aspiration system, you should take care of technical expertise and invite experienced designers.

Features of the installation of such structures

Since considerable volumes of contaminants are transported through the air ducts of the suction systems, increased demands are made on such structures in terms of strength, in contrast to the supply ventilation systems.

For their manufacture, steel with a thickness of 1.2 to 5.0 mm is used, and for shaped parts it is recommended to take steel, the thickness of which is 1.0 mm greater than the material of the duct.

Do not mount the suction ducts with clamps on the suspension. Only the use of clamps fixed with brackets is allowed, in some cases chains are used as fasteners.

The maximum distance between the brackets should be three meters for pipes with a diameter of more than 40 mm and four meters for structures with a diameter of 400 mm or less. These parameters will provide sufficient structural strength and reduce the risk of duct breaks during operation.

Another feature of the suction ducts is that they often have to be disassembled in order to clean from the accumulated dirt on the walls. In addition, as a result of rapid wear, individual elements have to be replaced periodically.

For this reason, it is recommended to use quick-disconnect coupling elements for installation of structures, rather than traditional flanges that quickly fail from frequent disassembly-assembly.

To adjust the air flow, oblique gates are used, which show less resistance to the flow and better prevent the accumulation of contaminants. The use of throttle control valves in aspiration systems is not recommended. It is very important that the ducts are positioned at the right angle.

The position of the structure depends on the set air flow rate, which is determined by the nature of the contaminants removed. So, to ensure a speed of about 20 m / s, a slope of 60 ° is needed, for a speed of 45 m / s, an angle of less than 60 °, etc.

If the nature of the impurities allows predicting the accumulation of sticky dust in the air ducts, it is recommended that such industrial aspiration systems be initially designed with a view to the maximum speed of movement of air masses.

To facilitate the cleaning of the structure, special inserts of film, paper and other suitable materials are inserted into the ducts. Conventional domestic and even some industrial fans for aspiration systems are not suitable, even if they have a sufficiently high performance.

We need devices with increased resistance to wear, which can work under high load for a long time without interruptions.

A common problem for low-efficiency aspiration systems is air loss. To prevent this phenomenon, experts recommend choose fans with some power reserve. Air loss in practice can reach 30% compared with the calculated data.

Wrong choice of local suction can adversely affect the entire system. You can not choose this element without taking into account the features of the process.

In some cases, an umbrella type shelter will be effective, in others a “showcase”, a fume hood, a cabin, etc. This point must necessarily be agreed with the technologist at a particular production.

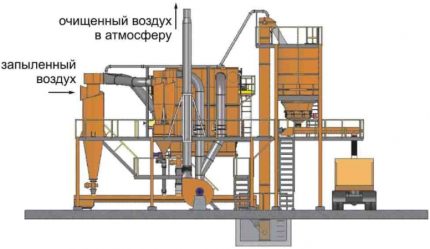

For rough cleaning of air from dust, dust bags, partitionless dust chambers, encased gas ducts, dry cyclones and other similar devices are used depending on the nature of the dust.

Scrubbers are often used for medium cleaning, and fine cleaning is carried out using a set of tools, which may include a cyclone type electrostatic precipitator and a bag filter, in some cases a high-pressure venturi pipe or other suitable units are used.

Why problems arise

Even if there is an aspiration system in the production room, it is necessary to periodically check the level of pollution in the air. It happens that the system operates normally, the filters are in order, but the air pollution remains too high.

The cause of the disadvantages may be some phenomena:

- dust accumulated in the ducts;

- low performance exhaust fan;

- too much air consumption;

- insufficient flow of fresh air masses.

If a large amount of dust accumulates in the ducts, this indicates that the project initially had too low speeds for moving air masses. Another reason for this phenomenon is flaws in the configuration of the elements of the aspiration system.

The presence of excessively sharp turns, sections with a small slope, the lack of a sufficient number of cleaning hatches, etc., can prevent timely removal of dust particles from the system.

Incorrect installation or errors can cause excessively high air losses in the system, resulting in a general decrease in device performance. Air leakage can occur as a result of improper operation of the filtration system. For this reason, when calculating it is recommended to lay a sufficient percentage for such losses.

If a sufficient amount of air passes through the system, but the operation of the system still does not demonstrate the expected efficiency, it may be necessary to revise the design of the local suction-shelter.

It should be located so as to collect the maximum amount of contaminants, preventing them from entering the room air. This structure is designed so that it does not interfere with the work and movement of personnel.

If the room does not receive enough fresh air, then it will not be enough to operate the suction system. In order to compensate for the increased efficiency of air exchange, a supply recuperated ventilation.

In hot workshops, heating of the incoming air from the outside is not needed, just make an opening in the wall and close it with a damper.

Conclusions and useful video on the topic

Here is an overview of the unpacking and installation of the RIKON DC3000 mobile aspiration system for the woodworking industry:

This video demonstrates the stationary suction system used in the manufacture of furniture:

Aspiration systems - a modern and reliable way to clean the air in industrial premises from hazardous pollution. If the design is correctly designed and installed without errors, it will demonstrate high efficiency at minimal cost.

Is there anything to supplement, or have questions about aspiration systems? Please leave comments on the publication. The contact form is located in the lower block.

Types of ventilation systems: a comparative overview of the options for organizing ventilation systems

Types of ventilation systems: a comparative overview of the options for organizing ventilation systems  Arrangement of ventilation to the ceiling: types of ventilation systems and features of their arrangement

Arrangement of ventilation to the ceiling: types of ventilation systems and features of their arrangement  Ventilation plastic pipes for hoods: the nuances of selection and installation

Ventilation plastic pipes for hoods: the nuances of selection and installation  Hood for bathroom and toilet: the subtleties of creating a project and the nuances of arranging the system

Hood for bathroom and toilet: the subtleties of creating a project and the nuances of arranging the system  How to make a ventilation calculation: formulas and an example of calculating a supply and exhaust system

How to make a ventilation calculation: formulas and an example of calculating a supply and exhaust system  Natural ventilation in a private house: rules for arranging a gravitational air exchange system

Natural ventilation in a private house: rules for arranging a gravitational air exchange system  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

The fact that aspiration systems is a very complex system for calculation and design was convinced from our own experience. The company in which I worked expanded production. We built our own carpentry workshop. Having a higher building education, he tried to design an aspiration system to remove dust and small waste from machine tools. There it was. I realized that there are too many nuances. Handbooks and manuals were not enough.Special knowledge is needed so as not to redo the entire system again.

Oleg, in the comments, of course, everyone writes, but why write so watery about what is already obvious? And those who themselves would like to try, and then saw your comment, could at least add some specifics. What specific knowledge is specific, and what are the most important nuances to consider? What problems did you encounter in the first place? More, more specifics.