What capacity for a septic tank is better to choose + how to make it yourself

The idea of building a septic tank sooner or later arises from any owner of a summer cottage or a country house. Local sewerage, along with water supply and heat supply, allows you to spend time outside the city without giving up the usual comfort.

Agree, not every summer resident is willing to spend a considerable amount of money to buy a septic tank. Many frugal owners solve the problem by constructing a wastewater storage facility on their own.

At the design stage of autonomous sewage, it is necessary to select a container for a septic tank, calculate its volume, study the requirements for the placement and installation of the tank. All these questions are detailed in the article.

The content of the article:

Types of septic tanks and their features

Septic tank is the main element of individual sewage system, which allows residents of a country house to use all the benefits of civilization (warm toilet, shower, dishwasher and washing machine, etc.) without poisoning the environment.

With its help, sewer water is effectively cleaned and disposed of.

The entire combination of these structures is divided into the following types:

- Storage device. So you can call a simple tank of plastic, dug in the ground. An ordinary hole is also considered to be a drive, the walls and bottom of which are isolated from the ground using bricks, concrete rings, or the continuous concreting method. In fact, we are talking about a cesspool, in which waste products are accumulated with their subsequent pumping and disposal.

- Overflow septic tank. This structure usually consists of two or three wells. Sewer drains are not only collected in them, but also treated in the process of settling and gradual separation when moving the waste mass from one chamber to another. Additional purification is carried out by anaerobic bacteria.

- VOCs (local treatment stations). These are the most modern, very convenient, although very expensive facilities. In addition to anaerobes with aerobes, multi-stage filtration systems, UV devices, etc. are involved in cleaning. There are many models of such stations, but their work requires electricity, which complicates their widespread distribution.

The first of these options requires regular drainage of the waste mass completely. In the second, clarified and treated waters must be passed through a soil purification system before disposal. The remaining fractions are removed using wastewater machines for this work.

The third type allows you to dump treated effluents into the soil, pond, ditch without performing additional treatment procedures.

Regardless of the technical complexity, degree of purification and dependence on energy supply in septic tank device the same types of containers are used, made of polymer compounds, concrete or brick.

The final choice of capacity for a septic tank is affected by:

- estimated volume of effluents;

- type of soil in the area of installation of the future structure;

- proximity of groundwater to the earth's surface;

- operating conditions of the facility - seasonality, intensity, etc .;

- the complexity of future installation work;

- the cost of materials and services.

It is possible that, choosing a container, you will come to the conclusion that it is easier and more convenient to build a septic tank yourself. Well, consider this scenario.

Manufacturing technology of homemade septic tanks

Like any other thing, a septic tank can also be done with your own hands. The requirements for this product will be unchanged. This most important element of the local sewage system must be functional, durable and safe to operate.

For the manufacture of containers for septic tanks do it yourself using a variety of materials: concrete rings, bricks, eurocubes and so on. Even used tanks of various purposes and car tires will do. Consider the most popular methods for the independent manufacture of the containers we need.

Concrete rings are the most popular material.

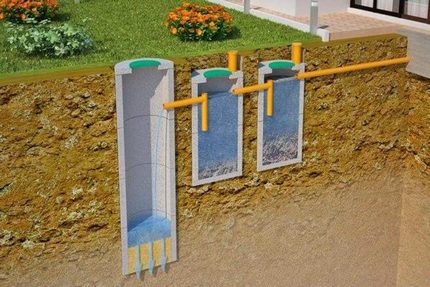

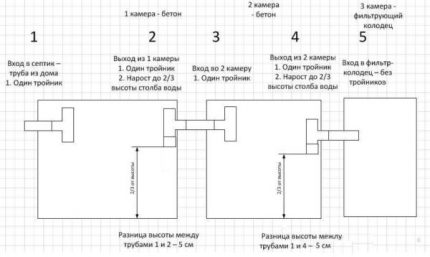

It is believed that it is the capacity of concrete rings easy to install and maintain. Therefore, they are most often used for the construction of septic tanks. An overflow sewage made of such material may, for example, include two or three wells, each of which has its own purpose.

In the first well of concrete rings, the bottom is also concreted.A drain pipe is brought to it, along which sewage will move. The slope towards the well when laying the drain pipes should be 2 cm per meter.

Inside the well, heavy fractions are separated from the lungs. The first settles to the bottom, and the second goes to the next tank.

As a rule, the second tank differs from the first only in size: it can be smaller. This is where the effluent is filtered. Filtering materials are used for this: expanded clay, gravel and others. Treated effluents are sent to the third well. Of this, the third in a row, the liquid should be absorbed into the soil.

This design has a number of advantages:

- Simplicity. The design is really plain. Its construction does not require deep knowledge. Need physical strength and minimal information about the basic rules of the sewer.

- Relatively low cost. If you compare the costs of constructing a septic tank from reinforced concrete rings and concreting a container with your own hands, then the rings will cost less.

- Construction speed. If the deadlines for commissioning the local sewage system are running out, then the concrete structure is what you need. It can be built quite quickly.

In addition, this structure is characterized by increased resistance to mechanical damage, has a significant usable volume.

There are construction and cons:

- Design Features. A well consisting of massive concrete rings may not be heavy enough to withstand the movement of expanded soil in an area where such a danger exists in principle. The septic tank rings are best welded to each other using brackets or metal plates.

- Difficulties in the installation process. Much attention should be paid to sealing joints. This is a rather time-consuming process that requires attention and concentration. With insufficient sealing of joints, untreated sewage can get into the ground.

- Costs of special equipment. The fact that it is necessary to deliver the rings to the assembly site of the septic tank by special transport is clear. But even in the installation process, you may need a crane, which will increase the total cost.

There are two options. mounting a septic tank from rings.

Option number 1. You can dig a common pit using an excavator. All rings are installed in it with a crane, after which overflow pipes are laid, all cracks and joints are closed.

Wells are sealed and insulated, then covered with soil and compacted.

Option number 2. With it, the lower rings of the wells are first installed on the ground, and excavation is carried out inside them and under the wall. The rings sink into the ground under the influence of their own weight. In this case, initially the wells will not have a bottom. It is poured later in each of the storage wells, which somewhat reduces the reliability of the design.

Insulating a septic tank with the second method becomes more difficult. For laying overflow pipes, you will also need to dig trenches. This is a more time-consuming and relatively long method, but it can be used by those who want to do all the work on their own.

Our task is to figure out how to make a tank for the septic tank yourself. And from the installation method, the method of creating the well does not change. Therefore, we consider in more detail the first installation method with digging a common foundation pit.

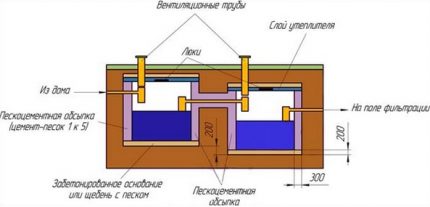

The construction process includes a number of standard steps:

For storage wells, we select rings with locks: their degree of sealing is higher, they are easier to install and less likely to shift in the event of frost heaving.

Even before installation, it is recommended that they be treated with Penetron-type impregnation or bitumen mastic for waterproofing.

The bottom of the pit is covered with rubble 20 cm thick. It should be well compacted, while achieving a strictly horizontal surface. The quality of work can be checked by a building level of 2 m.

Rings with a bottom are placed on the rubble. Between the storage wells we leave a gap of 0.5 m, which will be filled with soil and, in case of its movement, will play the role of a buffer. The walls of the initial rings should be strictly vertical so that the well is more stable.

If a decision has been made to fill a monolithic concrete slab under the accumulation wells, then its thickness should be at least 30 cm, and the sole by 20 cm from all sides should exceed the area occupied by the wells. The plate must be flat and strictly horizontal.

In this case, the first rings can be mounted only after the concrete has matured, and it will take 28 days.

The joint of the initial rings with the plate is sealed. For this, a Aquacement roller is laid under the ring - a concrete mortar with high waterproofing properties.

The Aquacement residue squeezed out from under the base is used for the joints of the rings. The rings are placed one on top of another, forming a well. All joints and cracks between them are coated with Aquacement concrete mortar and treated with a waterproofing compound.

Toxic compounds should not enter the well, otherwise they will disrupt the decomposition of bio-inclusions of effluents.

Connections with metal brackets mounted externally serve as additional fixation of the rings to each other. The “inputs” of the brackets are concreted and protected with waterproofing.That part of the septic tank, which is located above the freezing depth, is insulated with polystyrene foam.

Often over the upper part of the wells set the neck. They are made in order to save the volume of the empty part of the septic tank, which is higher than the overflow pipe.

Such necks are made of bricks coated with cement and waterproofing, finished reinforced concrete products or monolithic reinforced concrete, made by hand using formwork.

There are features of the installation of the third filter well or an absorption column. For her, the pit should be deepened down to sandy soils that can drain water. The bottom of the pit is covered with crushed stone by 20-25 cm, and then by sand - 30-40 cm. The lower ring of this well should not have a bottom.

If the filtration properties of rocks uncovered by the column are insufficient for the unimpeded disposal of treated wastewater, for example, in the sandy layer there are layers and lenses of sandy loam, then I arrange side filters.

In this case, perforated rings are added to the column. The holes in them are not less than 30-50 mm in diameter so as not to clog the soil.

The soil surrounding the filtration column would also be good to replace with crushed stone. In this case, the treated effluents will be easier to absorb.

Eurocubes - an excellent basis for a septic tank

Plastic is an ideal choice, as this material will not burst even in case of severe frost. In addition, septic tanks built from plastic containers serve for a long time, as Does not respond to aggressive environments.

Eurocubes are light in weight, which provides additional installation benefits. For their installation does not need special equipment. External frames allow you to fill the Eurocube with earth: they do not deform.

It will take 72 hours for a high-quality sewage treatment. The required total capacity of the septic tank will depend on the total amount of water used by all residents of the dacha in three days.

Considering that one person on average consumes 200 liters of water per day, a family of three consumers needs a septic tank consisting of three tanks and containing more than 1800 liters of liquid.

Before you start digging a pit, you need to measure the tanks, after which they begin excavation. A sand pillow (30 cm) is poured at the bottom of the pit, then concrete (20 cm) is poured.

So, the depth of the pit should exceed the height of the eurocube by 50 cm and the top layer of the backfill. A Eurocube placed in a pit should be 30 cm away from its walls around the entire perimeter.

If the groundwater in your area is close to the surface and there is a risk of a lightweight plastic septic tank floating up, it must be made heavier by fastening with plastic straps to the concrete base or at least to standard curb stones, placing them on both sides of the structure.

Additional recommendations for choosing a septic tank for high groundwater are given in this article.

Cubes should be cascaded so that the drains flow from the upper to the lower independently. The first tank enters the pipe coming from the house, and the outlet goes to the adjacent tank. It, in turn, is connected to the third cube, the tap of which goes into the filtration field.

In addition to Eurocubes, 6 tees and plastic pipes of 150 mm diameter will be needed for transitions between cubes and the creation of ventilation holes.

To prepare the eurocubes for installation, you need to cut holes:

- around the neck of the cube so that a tee passes into the container;

- on the side of the cube 20 cm from its top for the incoming pipe, which is connected inside the compartment with a tee;

- on the opposite side surface 40 cm from the top for the outlet pipe going into the adjacent cube;

- on the cover for mounting the ventilation pipe.

The septic tank is assembled sequentially from the first tank to the second, and from it to the third. Each subsequent cube should be 20 cm below the previous one. You can do just two cubes, which will significantly reduce the cost of work. All connections of the structure are carefully sealed.

To fill the pit, you need a mixture of five parts of sand for one part of cement. The dry components of this mixture are mixed, covered with a layer of 30 cm, and then rammed.

Do the same with subsequent layers. At the same time, the cubic chambers are filled with water so that the soil being filled up does not deform them. The upper part of the cubes is protected from freezing by foam sheets or filled with penoizol.

Brick tank - long but reliable

The owner who took build a septic tank out of brick, possesses decent reserves of time, knows how to handle not only a shovel, but also a trowel, ready for painstaking work in the hope of a long-term construction.

After making preliminary calculations and determining the volume of the future foundation pit, you can proceed to its construction.

The advantages of this choice include:

- availability of source material;

- the brick product is designed for long-term operation;

- bricklaying requires certain skills, but their absence can be supplemented by the ability of a home master to adapt to any work;

- all models of septic tanks can be made of bricks;

- The brick tank can be of any size, which makes it easy to correlate it with the parameters of the site.

The disadvantages include the need for additional insulation of the brick, since it does not initially have special insulation properties. In addition, the construction of this facility will have to spend a lot of time and effort.

For work, you will need bricks, of which a full clinker 240x115x71 is preferable. The walls will be erected with single-row masonry, and the wall in two bricks.

It is necessary to prepare:

- sand;

- cement ШПЦ400 (not lower);

- waterproofing material such as bitumen mastic;

- 10 mm thick stainless steel fittings;

- for each of the cameras a cover with a hatch;

- tools for excavation and construction work.

The finished pit should be 10-15 cm higher than the corresponding dimensions of the future structure. Installing temporary formwork will prevent soil shedding. On a flat bottom of the pit, 20-30 cm of gravel are poured, and then 40-50 cm of sand.

The resulting pillow is moistened with water and rammed tightly. A reinforcing mesh is laid on top of it, which is poured with concrete (30 cm) and left to solidify for 10 days.

According to the scheme, the walls are removed, leaving gaps for the pipes. It is recommended to add liquid glass to the cement mortar to increase strength. Waterproofing is carried out using bitumen mastic, applying a layer of 3 mm. The finished tank is equipped with ventilation, an upper plate is installed, on which there is a hole for the hatch.

They fill the brick structure with clay, after connecting the septic tank to the sewer system. The work of the finished structure is checked by filling it with clean water. An clay castle with a width of 1 meter and a depth of half a meter can be used as the external insulation of the structure.

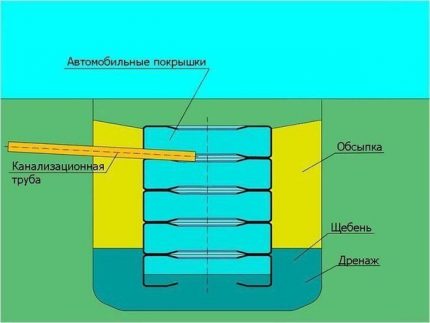

Old tires are also an option

The most budgetary material from which they make containers for a septic tank is old car tires. The advantages of this option are obvious - it is affordability and straightforward installation.

However, the disadvantages of the method are also obvious:

- with the help of such a septic tank, only a small amount of effluent can be processed;

- a septic tank from tires is cumulative, that is, it involves periodic pumping of accumulated contents;

- joints and tires themselves are problematic to seal, so there is a high risk of contamination of the soil with sewage.

Volume septic tank depends on the norm of water consumption by one tenant of the house and the total number of residents. As a rule, 5-7 tires per well are enough. However, tires are also different.

Installation of a treatment plant is simple. Before digging a foundation pit for a septic tank from two wells, you need to mark out the territory. The dimensions of the wells are marked with tires, laying them on the ground.

The tire for the second tank is placed close to the first. It may be larger: the second well is better to make more than the first. After marking under both tanks, we dig one hole.

The bottom of the well must be protected from the penetration of wastewater into the ground. To do this, it is either concreted or a clay plug made of clay with a thickness of 20-25 cm is made on it. The well itself is made up of tires, in which the upper part is removed using an electric jigsaw.

The strength of the connection of the tires to each other is ensured by their pairwise bundle: the upper tire is tied with wire to the lower one. All seams, punctures and joints reliably seal.

The adapter pipe is inserted into the hole, which is cut at a height of 2/3 from the bottom of the pit. For the incoming pipe at the top of the first well, you also need to cut a similar hole.

Plastic pipes are used to transport wastewater. The foundation pit should be filled up with sand and the soil that was excavated during digging. For each of the wells you need a cover made of a material that does not rot - you can choose polymer sewer manhole.

Conclusions and useful video on the topic

The visual representation of any process is better perceived than the printed word. That's why we put all these videos together.

See how you can independently build a septic tank, consisting of three wells, using factory-made concrete rings for tanks:

The happy owners of Eurocubes have almost perfect material for the construction of individual sewers. It is important not to forget that the relatively small weight of the cubes themselves can be a problem when swelling the soil.

How to use Eurocubes, look at the video:

Often when building different objects, bricks are used. They can become good material for a septic tank. The nuances of such a structure will be opened for you by the video:

The choice of material for a septic tank is not an easy task. It is necessary not only to estimate their financial capabilities, but also to find out the features of the area where this building will be operated. Having collected all the necessary information and armed with information, you will make a choice that you will not have to regret later.

Have experience in solving such problems? Or have questions about the topic? Please share your opinion, tell us which septic tank capacity you use. You can leave comments in the block below.

How to make a septic tank out of rings with your own hands: schemes and options + step-by-step instructions

How to make a septic tank out of rings with your own hands: schemes and options + step-by-step instructions  Do-it-yourself monolithic concrete septic tank: schemes and rules for arranging a concrete septic tank

Do-it-yourself monolithic concrete septic tank: schemes and rules for arranging a concrete septic tank  How to make a septic tank from European cubes with your own hands: step-by-step assembly instructions

How to make a septic tank from European cubes with your own hands: step-by-step assembly instructions  How to make a septic tank with your own hands from barrels using plastic containers as an example

How to make a septic tank with your own hands from barrels using plastic containers as an example  Installation of septic tank “Topas”: do-it-yourself installation + service rules

Installation of septic tank “Topas”: do-it-yourself installation + service rules  DIY septic tank installation: installation and maintenance instructions

DIY septic tank installation: installation and maintenance instructions  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Here I am convinced once again that not everything can be done with one's own hands. Well, why invent a bicycle. It is better to order a container for a septic tank, it will not cost so much than then try to fix the leak or some other problem. For me, this is already a completed stage. We have a drive in the country, for 3 rings, it’s enough. It’s convenient, we are there every weekend.

For each, this process will be individual. It is important to note that plastic containers are cheaper and lighter than concrete rings.This makes it possible to transport them without additional physical strength, and, accordingly, without additional costs. Personally, I bought a plastic container and installed it myself in the country without effort. Already 2 years in operation. I advise those who want to buy such containers, first figure out which types are better for them.