How to choose enamel for bath restoration: a comparative overview of popular products

Sooner or later, everything becomes worthless. This applies not only to things, but also to plumbing equipment. A bathtub, which until recently has shone with whiteness, after some time will inevitably turn yellow, lose its luster and become covered with a network of cracks.

Agree, a complete replacement of plumbing is an expensive and troublesome event. If the integrity of the bowl is preserved, then it will be possible to extend its life by repainting the surface of the bath. Such a service can be ordered from a specialized company or do the work yourself. The main thing is to choose a quality composition.

Before you choose the enamel for the restoration of the bath, you need to find out more information about the products presented in plumbing stores. We described in detail the pros and cons, as well as the specifics of applying different formulations.

To make it easier for you to make a choice, we offer you to read a review of popular enamels that have received many positive feedback from consumers. Among them are goods of domestic and foreign companies.

The content of the article:

What is enamel bath?

Each cast iron bathtub undergoes a complex enameling process during the manufacturing process. The enamel itself on its surface is a special glassy substance, which under special conditions is applied to the surface of the bowl. This occurs in several stages by spraying.

Enamel powder is applied to the very hot inner surface of the bath. Under the influence of high temperature during firing, it is baked.

This procedure is repeated several times until a strong enamel coating of sufficient thickness is obtained.It is clear that at home it is impossible to repeat this procedure.

However, manufacturers offer tools for the so-called cold enameling. She suggests that the enamel will be applied without firing. The resulting coating can only be arbitrarily called enamel, it will have other performance characteristics.

Home restoration: pros and cons

Before deciding to enamel the bath at home, its owners, as a rule, find a lot of positive and negative reviews from those who have already done this. Let's try to systematize them.

So, from the advantages of self-enameling can be noted:

- Aesthetics. The ability to get an updated bath without dismantling the old equipment and without carrying out related repairs.

- Availability. The cost of funds for restoration is relatively low.

- Self-painting option. Work on cold bath enameling, if desired, can be done with your own hands, therefore, save on the services of specialists.

- Color variations. Enamel, which is applied to the bowl, can have almost any color. It is obtained using a tinting agent that is included with the enamel or purchased separately.

- Maintainability. The coating obtained during the process of cold enameling is subject to restoration.

Home enameling also has disadvantages.

It should be noted that they are quite weighty:

- Fragility. The life of the applied coating is much shorter than that of factory enamel. It depends on the material that covers the bath. On average, such an enamel is enough for 5-8 years, after which you can apply a new layer of funds for restoration.

- Low stability to various mechanical damage. Even a not very heavy object falling into the bathtub from a small height can damage the coating.

- Chemical sensitivity. Bleach, paint, photo reagents, etc. compounds provoke a change in the shade of enamel.

- Exacting care. AT cleaning products There should be no abrasives and bleaches. Ideally, the bath should be washed with ordinary soapy water.

We have listed the main advantages and disadvantages of home enameling.What outweighs, everyone decides for himself.

The only thing I would like to pay special attention to is the correctness bath restoration. If all the requirements of the manufacturer of the product are not exactly met, the new coating will not show the declared operational characteristics, it will be fragile and will last very short.

The process of applying an enamel coating to the inner surface of the bowl of your favorite plumbing involves several standard steps:

What you need to know about enamels

Enamel reducing agents for baths are plentiful. They differ not only in composition, but also in the method of application.

Enamel can be laid on the base with a brush or roller. In this case, the composition should be quite thick. It is best to take a hard brush so that it makes it easier to rub the enamel on the base. It is advisable that the bristles from the brush do not come out, this will spoil the attractive appearance of the bowl.

Enamel is easier to apply with a roller. It distributes the composition as evenly as possible, but it is impossible to completely treat the entire bowl with a roller. Where it bends, you need a brush.

Another method of applying enamel is spraying. Professionals most often use a spray gun in their work. A liquid composition is poured into it, which is applied in several layers. For non-professionals, this option is often unacceptable due to complexity.

You can use a spray can with special enamel. With proper application, a sufficiently strong and uniform coating is obtained. If the work is carried out incorrectly, the color may be uneven and spots of different shades will appear on the surface of the bowl.

Some experts believe that enamel in the form of an aerosol is optimal for masking small defects, but not for the restoration of the entire bath.

When buying a product, you should pay attention to its configuration. Best of all, if it includes a means for pre-treating the bowl, possibly even with a special application tool.

It is desirable that tinting compositions are included in the kit, allowing you to get any desired shade. If a two-component enamel is purchased, it is worth looking at the color of the hardener. Dark tones are not recommended. They can give an undesirable shade to the finished product.

Varieties of compositions for cold enameling

Restoration of the bath can be carried out in different compositions. Consider the main types of varnish and varnish materials used for this purpose.

Two-component epoxy enamel

It is a suspension in which epoxy resin, fillers and pigments are present. The peculiarity of the material is a two-component composition, therefore, hardener is added to the solution before application and mixes well.

A ready-to-use composition must be used for a limited amount of time; it hardens quickly enough.

The advantages of epoxy enamel include:

- after hardening the composition, a uniform, glossy, very smooth coating is obtained;

- good adhesion to cast iron and other metals;

- high wear resistance and strength - correctly applied coating can be cleaned with abrasive products, it will last about 15 years;

- epoxy enamel is insensitive to alkalis and acids;

- the cost of the material is relatively small.

Such enamel also has significant disadvantages. First of all, it is toxicity and a sharp unpleasant odor. When working with the composition, wear a respirator and protective rubber gloves. The material is prone to sagging, therefore, the manufacturer's recommendations regarding the consistency of the solution should be strictly observed.

Given the high speed of hardening of epoxy enamel, you need to work with it quickly. This can be inconvenient for those who are trying to restore an old bath for the first time. Another minus - over time, the coating may turn yellow, this is especially true for compositions with a hardener of a dark color.

Aerosol products

In the form of an aerosol, various enamels can be produced: epoxy, acrylic, one- and two-component. This must be considered when buying. The composition in the can is completely ready for application, it only needs to be shaken well.

Advantages of using aerosols:

- simple and quick application of the composition - no tools are required for this;

- aerosol enamel fits well, the coating is smooth and shiny;

- special additives in the compositions make it possible to imitate different textures, to obtain a pearlescent or fluorescent surface;

- it takes several hours to completely harden this type of enamel.

Among the disadvantages is the small thickness of the applied layer. The composition in the can is very liquid, due to the peculiarities of its application. It contains a large amount of solvent.

Therefore, the enamel lays on the surface with a very thin layer, which is quickly erased. For the same reason, the foundation must be carefully prepared.

Enamel from a spray can not cover small defects in the bowl, such as chips or cracks. Mixing compositions from different spray cans in order to obtain a new shade is not allowed. If the application of enamel did not comply with the manufacturer's requirements, it will lie unevenly. Leaks or streaks may appear.

Latex or Acrylic Enamel

Also known as liquid or bulk acrylic. The material is an acrylic two-component enamel, so it needs to be mixed thoroughly before use. As a result of using the composition, a glossy uniform coating is obtained.

The advantages of liquid acrylic are:

- high resistance to abrasion, as well as to various mechanical damage;

- thermal conductivity is low, which makes it possible to keep heat well;

- over time, the coating does not lose whiteness;

- the bowl covered with acrylic becomes non-slip and therefore safe to use;

- good adhesion to substrates of various materials: cast iron, steel, acrylic;

- simplicity in leaving.

There are also disadvantages to the coating. The material has a pungent odor, so you can work with it only in a respirator. Acrylic enamels do not fit well on a plastic base. To improve adhesion, additional preparatory work will have to be carried out and the base must be primed.

Preparing the bowl is done anyway. If it is carried out poorly, the coating will begin to peel off over time.

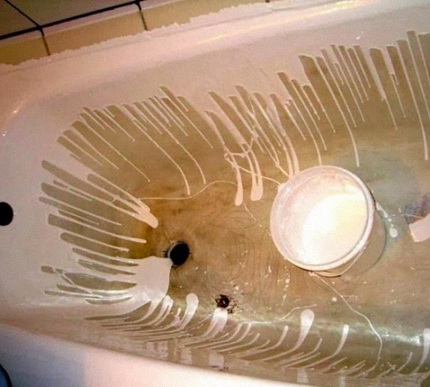

Liquid acrylic is applied to the bowl by pouring. This means that the thick composition is carefully poured onto the side, from where it flows down into the bowl on its own, forming a new coating.

This way applying liquid acrylic requires a large amount of material, so its consumption is much higher than when applied with a roller or brush. Accordingly, the financial cost of acquiring enamel is quite significant.

In order to cover the bathtub with liquid acrylic, you need to perform a number of traditional actions:

Overview of popular bath restoration enamels

The range of materials for restoration of the bowl is large, so it is very difficult to say which enamel for the bath is considered the best. For each bath, the composition should be selected individually, taking into account the characteristics of a particular product. Practice shows that such compositions are most in demand by consumers.

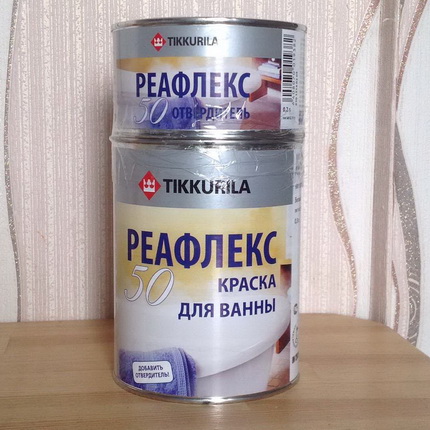

Reaflex 50 from the famous Tikkuril brand

Epoxy two-component material designed to restore enameled baths. It can be used for concrete pools.Available in white, high gloss. The manufacturer warns that over time, the composition may turn yellow. Only solvent is used to dilute the composition. Novopox.

Enamel can be applied to the substrate by various methods: roller or brush, as well as spraying at low or high pressure. For each type of application, a specific density of material is selected. Before work, you need to prepare the composition.

For this, four parts of enamel and one part of hardener are mixed. The solution can be operated for four hours after mixing.

The composition dries for a long time. Drying "from dust" occurs within one hour, and the complete hardening of the layer takes from eight hours to two days. After this time, each subsequent layer is applied. After restoration, the bath will be ready for full operation only after seven days.

Before starting work, the old enameled surface is cleaned, sanded to a matte state, washed and degreased. Further, priming with enamel diluted by 20% is mandatory. Reaflex.

After that, if necessary, defects in the base are closed. Eight hours after priming, you can begin to apply enamel. It is laid in at least two layers.

Epoxin 51 and its variety Epoxin 51C

Two-component epoxy-based enamels. As the second component, a colorless transparent hardener of amine type is used, which protects the finished coating from yellowing.

As a result of application Epoxin a glossy uniform coating is formed. The working composition is quite thick, so it can mask small defects in the base.

The solution is mixed immediately before application. The exact proportions for mixing are indicated on the packaging of the material. The composition can be diluted with solvents R-12, 647 and 646. For applying enamel, you can use a brush or a roller.

After applying the hardener, the composition must be used within 50-60 minutes, after which it is unsuitable for use. The manufacturer recommends diluting the enamel separately for each of the applied layers.

Before starting work on applying enamel, the bowl must be thoroughly cleaned until the gloss is completely removed. Then sand all the defective areas present on it to a metallic luster. The largest of them are recommended to be putty.

The surface of the restored bath is freed from dust and washed. After that, in order to warm up, hot water is collected in the bowl for five minutes. This is necessary to quickly dry the bath.

After the hot water is drained, the bowl is wiped dry and dried. On the surface thus prepared with a flat brush, the first layer of the product is applied. The composition is thick, which makes it difficult to apply, since leaks easily appear. They must be rubbed immediately with a brush.

After the first layer has dried, which takes about an hour, the second layer is applied. Full curing of enamel occurs in a day.

Aerosol KU-130 from KUDO

Enamel is made on the basis of modified artificial resins. Designed for restoration of enameled and ceramic coatings. The enamel coating is distinguished by high strength, good adhesion to various substrates, resistance to detergents and long service life.

The enamel is completely ready for use, before applying it, the bottle is thoroughly shaken.

The manufacturer does not recommend working with the composition at an ambient temperature below + 10 ° C. The surface of the bowl before applying the enamel must be well cleaned and sanded. All base defects must be puttied.

The composition is liquid, so it does not cover even small flaws on the surface. The base must be degreased. To do this, it is recommended to use a solution Silicone Remover of the same brand.

On the prepared base, the enamel is applied in two or three layers from a distance of 0.25-0.3 m. After applying each layer, it is allowed to dry for 20-25 minutes, after which the next is applied.

Full drying of the enamel occurs in a day. You can use the bathroom restored such a composition after three days after applying the composition.

Eco Acrylic Liquid Acrylic

The manufacturer produces several formulations that differ in additional additives. The line has an antimicrobial, fast-drying and bactericidal coating. All materials are enamels of a two-component type, require mixing before application to the bowl.

Liquid acrylic from Eco baths It has a low odor, non-toxic and completely environmentally friendly.

For applying the composition, the filling method is used, and this requires certain skills. The consistency of enamel is such that it is applied without bubbles and sagging. No impurities in the solution.

Properly applied coating will last up to 15 years. It is possible to work with the composition only at temperatures from + 21 ° С to + 26 ° С, the temperature should be from + 23 ° С to + 25 ° С.

Before applying enamel, the bath is thoroughly cleaned, washed from dust and dirt, and then degreased with acetone. The bowl is dried, and you can begin to apply the composition. It is poured in a circle along the sides of the bath and, if necessary, is distributed with a soft rubber spatula.

After applying the enamel to the bowl, it should dry for a day, after which you can install overflow.

Some enamels touted to be suitable for bath restoration are actually not. These include alkyd compounds. Theoretically, they can be applied to metal, but the surface should be especially carefully prepared and primed.

In addition, alkyd paints are prone to sagging, which is quite difficult to deal with. It is necessary to impose such a composition in at least three to four layers. At the same time, the service life of the coating will be only 5-6 years.

Conclusions and useful video on the topic

Watching a video is a great opportunity to see the practical application of enameling old bathtubs and learn basic skills.

How to properly restore the bath using enamel and brush:

We restore the bath with an aerosol:

What is the loading method - all the subtleties of the procedure:

Finally, I would like to once again advise you to carefully choose a tool for restoration of the bath. An abundance of such compounds can be misleading. It is important that the material is of high quality.

There is a certain guarantee when buying enamel of a popular brand. Otherwise, all the laborious work of preparing the bowl and applying the composition will not give the expected result and you will have to do it again or, what I really do not want, change the bathtub to a new one.

Have experience restoring an old bath and using enamel? Please tell our readers what tool you used, share your observations regarding the quality and ease of application of the composition. Leave comments and participate in discussions - the feedback form is located below.

Polypropylene or plastic pipes: a comparative overview and the choice of the best option

Polypropylene or plastic pipes: a comparative overview and the choice of the best option  Glue for PVC pipes: an overview of the best compositions and instructions for use

Glue for PVC pipes: an overview of the best compositions and instructions for use  How to choose an iron for welding polypropylene pipes and how to use it correctly

How to choose an iron for welding polypropylene pipes and how to use it correctly  A cable for cleaning pipes: types, how to choose the right + instructions for use

A cable for cleaning pipes: types, how to choose the right + instructions for use  How to choose a soldering iron for polypropylene pipes: tips from professional plumbers

How to choose a soldering iron for polypropylene pipes: tips from professional plumbers  Press pliers for plastic pipes: how to choose + instruction on use

Press pliers for plastic pipes: how to choose + instruction on use  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

You opened my eyes. I have long wanted to change the enamel in my bath. I thought that if it was “painted”, then the enamel would last about 20 years. I don’t feel like throwing away a good cast-iron bowl. I also heard about such a method as an acrylic insert “bath in bath”. Good or not? Of the affordable and easily feasible, almost everyone likes spray painting the bathtub. Most likely, I will use this method. Simple and budget.

Hello. Aerosol painting is one of the most difficult and subtle application methods. About acrylic liners here.

Isn't it better to cover the bath with acrylic? As for me, enamel is much more practical and more beautiful. Although the application process is more complicated. Is there such an article on the site?

Here, everyone at his own discretion decides what is the best way to cover a cast-iron bathroom during restoration. Enamel is easier to apply, with acrylic there are many nuances that need to be considered. As for the articles on the site on this topic, they are, and not even one. In my opinion this article best describes the process, especially the attached videos.

But during the restoration of the cast-iron bath, it must be borne in mind that over the years any applied coating will still turn yellow, even acrylic, even enamel - there is no difference. So every 5-6 years you will have to repaint or fill with acrylic on a new one. There is nothing to be done, these are the features of cast-iron van.