Warehouse and warehouse ventilation: standards, requirements, necessary equipment

High-quality warehouse ventilation is necessary to ensure occupational safety and optimal storage conditions for products. When equipping a ventilation system, it is necessary to adhere to the established norms of the frequency of air exchange, and choose equipment whose parameters correspond to the regulated requirements.

Before proceeding with the design of the engineering network, you should study the principles, as well as find out how to arrange warehouse ventilation, agree?

We will tell you about the features of the organization of natural and forced air exchange, list the requirements for equipment, and also give the normalized microclimate parameters for warehouses for various purposes.

The content of the article:

Basic principles for warehouse ventilation

Code of rules SP 60.13330.2012 “SNiP 41-01-2003. Heating, ventilation and air conditioning ”is the main document that spells out the requirements for the organization of ventilation of the premises for the storage of products used in household equipment, building materials and other products.

Features of natural air exchange

Natural air exchange of the warehouse occurs due to the difference in static pressure of the different-temperature air columns. Cooler street air enters the room through the air inlet, and internal air exits through the hood.

In the warm season, the supply openings are located at a level of 0.3 to 1.8 m. In cold weather, they are arranged at a distance from the floor of at least 3 m with a total room height of up to 6 m, and 4 m with a larger room height.

If the height of the warehouse is small, then a lower position of the holes can be designed, however, it is necessary to take into account the possibility of snow covering it and take measures to prevent this scenario.

Natural ventilation is almost impossible if it is necessary to process the incoming air. Cleaning it from dust through filters, heating or humidification creates resistance in the supply duct and significantly reduces the flow rate.

With natural ventilation, the main problem is the dependence of the flow rate on the parameters of the external environment. In case of excess air intake, manually or automatically operated flaps are mounted on the holes.

Insufficient air circulation can be partially compensated by setting ventilation deflector. A more effective way is the installation of forced ventilation.

Use of forced ventilation

According to paragraphs 7.1.3-7.1.4. a ventilation device, the functioning of which requires mechanical stimulation, is installed in the following cases:

- if the necessary microclimate parameters cannot be achieved with natural air circulation;

- if at certain times of the year there are such temperature and humidity characteristics of the outdoor air that natural ventilation does not provide the required microclimate in the warehouse;

- in the presence of rooms or their zones without natural ventilation.

The placement of exhaust openings must be carried out in the most contaminated parts of the warehouse. In the case of a non-zero balance of the volume of transported air, its compensation occurs due to the process of infiltration through the walls and roof of the structure.

The use of forced ventilation leads to the need to purchase and install expensive systems, as well as constant costs for electricity, equipment maintenance and activities aimed at compensating for its wear.

Therefore, combined natural and forced air exchange is often used. The operation of mechanical devices is used to compensate for the difference between the required volume of replaced air and ventilation capabilities.

Uncontrolled air exchange through infiltration

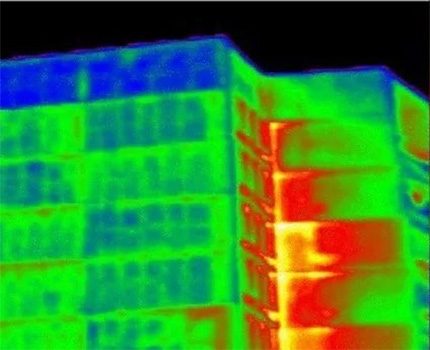

When calculating the parameters of equipment used to create the required microclimate, it is necessary to take into account air infiltration through the warehouse perimeter. The presence of leaks in the structures leads to uncontrolled inflow and outflow of air.

If compliance with a certain temperature and humidity is not necessary, then sometimes you can completely abandon any means of organizing ventilation in favor of infiltration.

However, if it is necessary to create a certain microclimate, uncontrolled air exchange creates problems. This is due to inconsistent environmental parameters and the volume of incoming air.

At minus temperatures, the exit of a warm stream through the slots promotes the formation of condensate and ice. This is fraught with the gradual destruction of the supporting structures, the formation of fungus and mold, an increased risk of short circuit and other problems.

Since the volume of infiltration is unstable and depends on many parameters, it is not taken into account in the normative calculation of air exchange. However, it appears with some assumptions when calculating heat loss and modeling the moisture index.

If infiltration in warehouses is undesirable, then it is necessary to eliminate the prerequisites for its occurrence. In addition to the presence of gaps in the walls of the building, there are other reasons leading to unaccounted air exchange.

On the windward side there is a dynamic pressure of the air mass on the wall of the building and the penetration of air into the room. Therefore, when designing warehouses, it is necessary to take into account the wind rose and not position the wall of the building perpendicular to the prevailing direction.

An effective solution to the problem can also be the installation of wind defenses.

On the lateral and leeward sides, the wind pressure is negative. As a result of the resulting difference, conditions are created for the outflow of air from the room.

To minimize the pressure gradient, it is necessary to adhere to recommendations on the geometric parameters of roofs and to eliminate the separation points of the boundary layer of the flow by installing wind-guiding elements.

The internal reason for the occurrence of infiltration may be the difference in the amount of supply and exhaust air. The unbalanced operation of the ventilation system leads to compensation for the missing or excess volume due to infiltration.

Therefore, periodic calibration of fans, cleaning of air ducts and filters, as well as other preventive maintenance are necessary.

Requirements for the installed equipment

Ventilation equipment works in conjunction with other devices to create and maintain conditions for normal functioning and technical condition of the warehouse. Therefore, it is necessary not only to comply with the requirements specified in SP 60.13330.2012, but also to take into account the provisions of other regulatory documents.

Basic rules for equipment placement

The power of ventilation equipment must be selected based on the estimated air circulation, taking into account possible volume losses due to incomplete tightness of the system.

In small warehouses, equipment is placed on the basis of the following principles:

- accessibility and convenience of preventive and repair work;

- compliance with fire and electrical safety requirements;

- availability of free space.

In large warehouses where compliance with standards is required, equipment is installed in a special room or on the roof of a building. It depends on the classification of the warehouse in certain categories of fire hazard.

Standby and emergency ventilation systems

In the event of a breakdown of the ventilation equipment and a shutdown of the system, an emergency situation in the warehouse may occur. A prolonged absence of air exchange can lead to damage to stored products and to the creation of conditions for a high concentration of undesirable impurities in the air.

Therefore, normative documents spell out the procedure for installing backup systems and their parameters.

According to clause 7.2.8, if people are supposed to stay permanently in the warehouse premises, then the air exchange systems must be equipped with redundant fans or two or more units are used.

According to clause 7.2.18, in rooms with a capacity of more than 10 tons and a high fire hazard category, it is necessary to provide a backup system that fully meets the need for air exchange.

An emergency situation with the release of a large amount of pollutants is also possible at the warehouse. The short-term operation of the ventilation system in forced mode will help to solve the problem. Demonstrate effective work suction systems.

According to paragraph7.6.1 the air flow rate and other parameters of the emergency system are determined on the basis of the provisions of the technological part of the project.

Hoods to remove the contaminant are placed depending on its density. If volatile components are heavier than air, then the nozzles are installed in the working area, and if it is lighter, then under the ceiling.

Climate control devices

The most effective way to ensure the temperature and humidity regime is the integration of air heaters and humidifiers in the supply ventilation. In this case, air will be supplied with predefined parameters.

Heaters can be of electric and water type. The second are more common for ventilation systems of warehouses and large complexes.

In a season with characteristic subzero temperatures, actual use heat recovery systems. This solution significantly reduces the cost of heating the warehouse.

Due to the presence of a separate zone for equipment, when choosing a recuperator or regenerator, you can only be guided by the financial costs and system efficiency. Noise level and mass of devices are not so important as when using them in apartment ventilation.

Rotary recuperators and water heaters have built-in or external motors. According to clause 7.2.7, it is necessary for them to provide backup motors and pumps in case of breakdown of the main components.

Microclimate parameters for typical warehouses

The microclimate parameters in warehouses and the air exchange rate are prescribed in NTP-APK 1.10.17.001-03 “Norms for the technological design of bases and general-purpose warehouses for resource support enterprises”, as well as in industry documents.

So, for example, the air environment parameters of a food warehouse depend on storage conditions and the nomenclature of specific products.

The concept of air exchange rate

Warehouse air exchange is necessary to achieve two goals:

- creation of a special microclimate of the premises optimal for storing this type of product;

- removal of harmful, explosive and other impurities and aerosols from the premises.

The calculation of the frequency of air exchange is performed according to the formula:

K (1 / h) = A / V,

Where:

- A - the volume of incoming air in one hour, (m3/ h);

- V - warehouse volume (m3).

For the storage of most types of products, normative documents prescribe a ventilation rate equal to one. With non-commercial use of the premises as a warehouse, often this figure is significantly lower. This is justified if ventilation of such power is guaranteed to provide the necessary indicators of temperature and humidity.

When commercial activities are required to comply with the requirements of regulatory documents on ventilation.

The total capacity of the installed systems should provide the air circulation of the necessary multiplicity. Otherwise, it is impossible to obtain a positive opinion from Rospotrebnadzor and the fire inspection on the intended use of the warehouse.

If there are several types of products in stock, it is necessary to provide microclimate parameters that satisfy the storage conditions of each of them.

Storage of building materials and products

When storing most types of building materials, the room temperature can be unregulated.Warehouses with rolled waterproofing bitumen-polymer and polymer materials used in the arrangement of roofs, foundations and walls of rooms with an unusually high level of moisture fall under the exception.

The air temperature in this case should not be lower than +50C.

Humidity in warehouses of this type is not standardized, except for the case of storage of bulk building materials. Do not allow moisture and contamination of cement, graphite and gypsum. Permissible relative humidity during storage is determined by the manufacturer and depends on the material and the method of its packaging.

Air circulation for sanitary-technical and sanitary-ceramic products is not standardized. For building materials, the required air exchange rate is taken equal to unity.

Features of wood storage

There are no general regulatory documents governing air in a timber warehouse. The main criteria when choosing ventilation is the humidity permissible for a particular type of material or finished product.

If the specificity of production involves the simultaneous receipt of a large amount of raw wood, then it is necessary to have forced ventilation, which is used immediately after loading the product. When the material reaches the natural moisture index, the mechanical purge is turned off.

In storage rooms with lumber, the microclimate is constantly monitored, using special humidity testers.

For uniform ventilation of wood and products based on it, their proper storage is necessary. It is necessary to observe the procedure for laying roundwood and lumber in stacks.

When transporting small items, the tight packing method is often used with space saving. After receiving such products in the warehouse, it must be decomposed or scattered so that all components are formed air access into the heap.

Otherwise, with high humidity of the material, favorable conditions will arise for the formation of fungus and mold.

Often a warehouse is equipped in the warehouse for primary processing of wood - sawing round logs or sawing edges. As a result of these works, wood dust of various sizes is released into the air. Her constant inhalation is a common non-infectious factor in the appearance of chronic bronchitis.

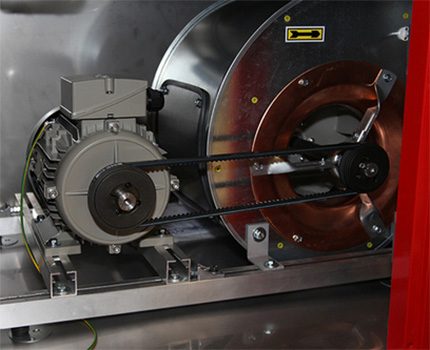

If dust is removed using general ventilation, the entire warehouse will become contaminated over time. Therefore, they provide for the installation of local chip and dust extractors of the cyclonic type with a separate hood, if such devices are not included in the set of woodworking equipment.

Storage of metal and equipment

For metal products, such as pipes, faucets, valves, temperature and humidity indicators are not standardized.

Electrical equipment and spare parts for internal combustion engines must be stored in compliance with anti-corrosion conditions.

Hand-held power tools, metal cutting and bench tools are stored at a temperature not lower than + 5 ° C and air humidity up to 70%.

For complex equipment, such as woodworking machines, manufacturers give recommendations on the temperature and humidity conditions during their conservation.

These requirements must be strictly adhered to, because complex units contain elements created using combinations of different materials, the properties of which can change if stored improperly.

Often the processing of metal products and equipment from corrosion is carried out directly in the warehouse.When performing it in order to avoid exposure to an increased concentration of toxic fumes, it is necessary to ventilate the room for 1-1.5 days.

In rooms where flammable and explosive substances are stored additionally should be equipped smoke ventilation.

Conclusions and useful video on the topic

The video demonstrates the organization of ventilation of a warehouse complex:

Installation device for removing sawdust in a separate hood:

Strict adherence to the requirements of regulatory documents on the ventilation of a warehouse will create the microclimate necessary for high-quality storage of products.

The variety of equipment offered will help to implement almost any system configuration, taking into account the required mode and design features of the building.

Have something to supplement, or have questions about the organization of ventilation of a warehouse? You can leave comments on the publication and participate in the discussion of the material. The contact form is located in the lower block.

Standards for ventilation and air conditioning: air exchange in rooms for various purposes

Standards for ventilation and air conditioning: air exchange in rooms for various purposes  Air exchange rates per person for various premises

Air exchange rates per person for various premises  Humidity in educational institutions: legal requirements and standards

Humidity in educational institutions: legal requirements and standards  Fire safety of ventilation chambers: rules and norms of equipment for special rooms

Fire safety of ventilation chambers: rules and norms of equipment for special rooms  Cleanroom ventilation: design and installation rules for ventilation systems

Cleanroom ventilation: design and installation rules for ventilation systems  Ventilation of industrial premises: rules for the organization of air exchange

Ventilation of industrial premises: rules for the organization of air exchange  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Properly organize ventilation in a warehouse with vegetables, for example, means preserving the harvest. Parents live in the village, they decided to seriously engage in the agricultural business: to grow vegetables, and then sell them. There was a question with storage. Converted a warehouse on which coal was previously stored.

We began by studying information on how to store vegetables, what needs to be organized and arranged for this. We came to the conclusion that ventilation was necessary, but it was not in stock before. For vegetables to remain edible, a certain temperature and fresh air are required.

We chose a supply air ventilation with a natural extract. In the first month, they did not take into account that vegetables breathe and emit carbon dioxide. Then added ducts that push the recycled air out.

We bought a nice warm warehouse, were going to store our equipment there. We didn’t stop right away, but six months later, the warehouse was empty. I saw that black mold went on the walls, talked with specialists and they told me that most likely the problem was in ventilation, or rather in its absence, because what was done did not meet the standards. I had to hire people and redo everything, it turned out a pretty penny, and I was still so happy that I took the room cheaply, and here they are pitfalls.